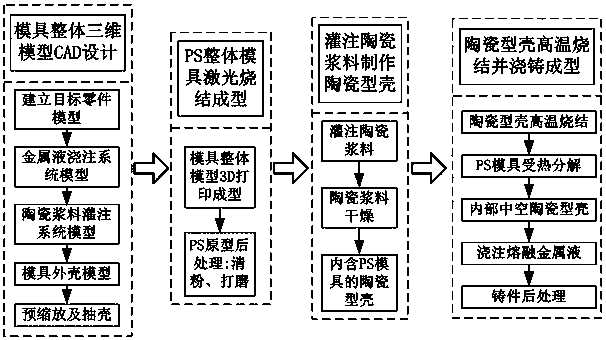

Ceramic mold casting PS (polystyrene) integral mold based on selective laser sintering and quick casting method of integral mold

A technology of laser selective sintering and rapid casting, which is applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc. It can solve the problems of not using laser selective sintering and single-piece casting, so as to improve product development efficiency and mold manufacturing cost. The effect of low and high dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0029] Example.

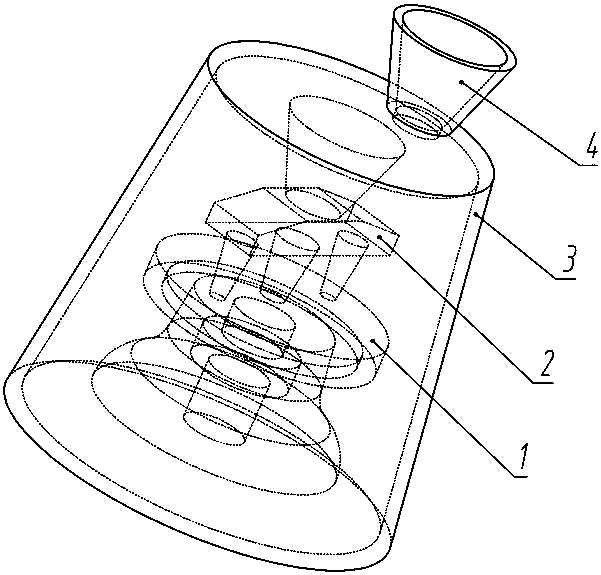

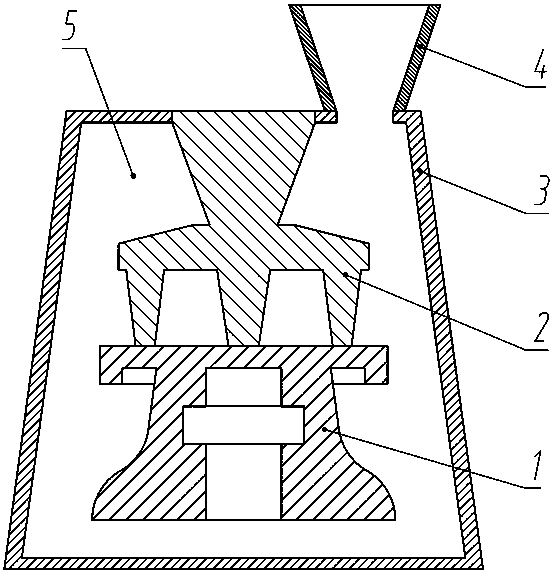

[0030] see Figure 1 to Figure 4 In this embodiment, the ceramic casting PS overall mold based on laser selective sintering includes target part PS model 1, molten metal pouring system PS model 2, mold shell PS model 3, ceramic slurry pouring system PS model 4 and ceramic slurry pouring cavity. Cavity 5, the molten metal pouring system PS model 2 and the target part PS model 1 are connected and fixed inside the mold shell PS model 3, and except for the connection and fixation, the outer walls of the molten metal pouring system PS model 2 and the target part PS model 1 are connected to A ceramic slurry filling cavity 5 is formed between the inner walls of the mold shell PS model 3, and the minimum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com