Lithium ion battery, coating separator and preparation method thereof

A coating and diaphragm technology, applied in the field of new energy, can solve problems such as battery deformation, battery efficiency reduction, safety hazards, etc., and achieve the effects of reducing the probability of short circuit, enhancing hardness, and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] The present invention also proposes a preparation method for preparing a coating diaphragm, comprising the following steps:

[0064] S1. Mix the inorganic compound particles, the surfactant, the first polymer binder and the deionized water uniformly according to the first mass ratio to obtain the first coating slurry.

[0065] The inorganic compound particles are ceramic particles, including one or more of aluminum oxide, silicon dioxide, magnesium hydroxide, boehmite, zirconium dioxide, calcium oxide, and zinc oxide, wherein the average particle size of the inorganic compound particles The diameter ranges from 0.1 μm to 4 μm; the surfactant includes one or more of alkylphenol polyoxyethylene ether, fatty alcohol polyoxyethylene ether, fatty acid polyoxyethylene ether, fatty amine polyoxyethylene ether; the first polymerization The polymer binder includes one or more of styrene-butadiene rubber, polyacrylonitrile, polyacrylic acid, and methyl methacrylate, wherein the a...

Embodiment 1

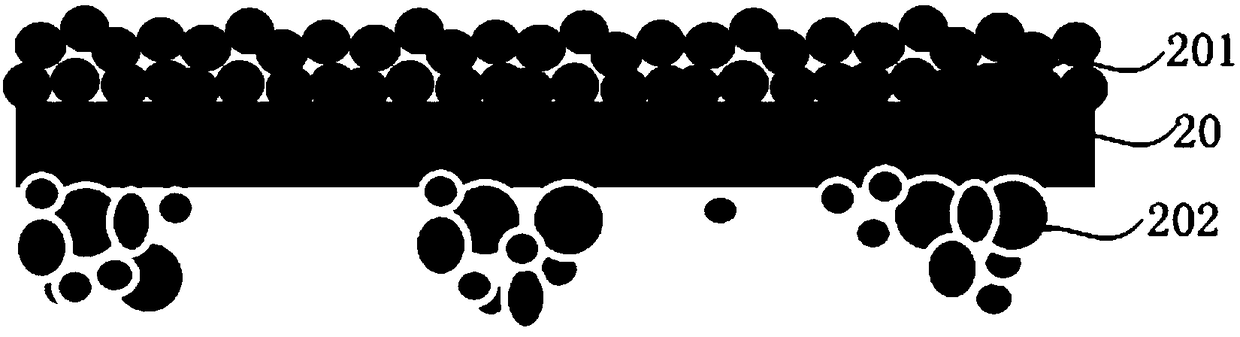

[0077] refer to figure 1 , is a schematic diagram of the structure of the coating diaphragm in Example 1 of the present invention. The diaphragm base material 10 selects a polyethylene porous film layer with a thickness of 12 μm; the upper surface of the diaphragm base material 10 is coated with a first coating 101 with a thickness of 3 μm; the first The upper surface of the coating 101 is coated with a second coating 102 . The inorganic compound particles of the first coating 101 use boehmite with an average particle size of 2 μm, the first polymer binder uses styrene-butadiene rubber with an average particle size of 0.5 μm, and the surfactant uses alkylphenol polyoxyethylene ether The organic compound particles of the second coating 102 are vinylidene fluoride-hexachloropropylene polymer with an average particle size of 5 μm, and the second polymer binder is styrene-butadiene rubber with an average particle size of 0.5 μm.

[0078] The preparation process of the embodiment ...

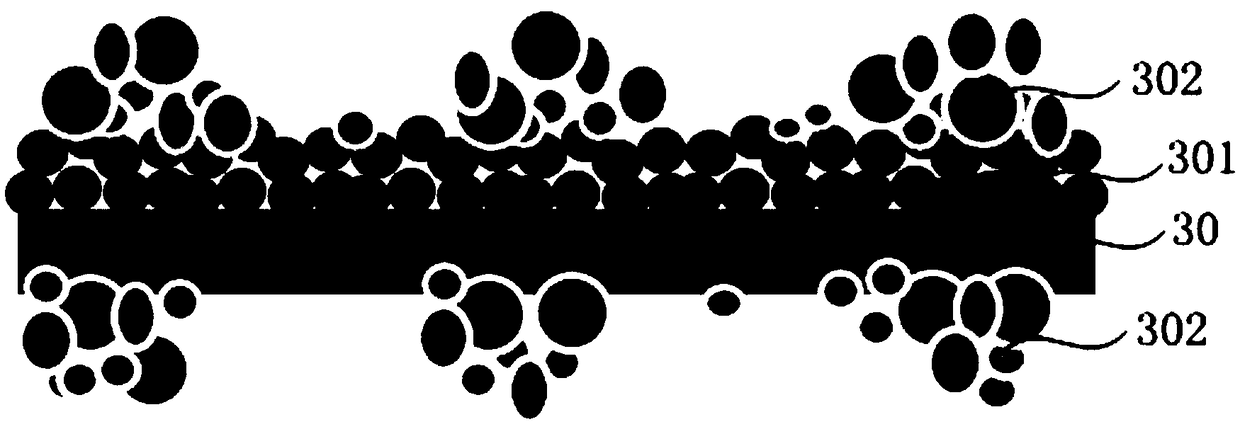

Embodiment 2

[0093] The structure of the coating membrane in Example 2 of the present invention is the same as that in Example 1.

[0094] The raw material is different from that of Example 1 in that the inorganic compound particles of the first coating 101 are aluminum oxide with an average particle size of 4 μm, the first polymer binder is polyacrylonitrile with an average particle size of 1 μm, and the surfactant Fatty alcohol polyoxyethylene ether is used; the organic compound particles of the second coating 102 are polyvinylidene fluoride with an average particle size of 5 μm, and the second polymer binder is polyacrylic acid with an average particle size of 1 μm.

[0095] The preparation method is different from that of Example 1 in that: the solid content of the second coating slurry is 13%, and the viscosity is 150 mPa·s. Adjust the flow rate of the pressure pump to deliver the second coating slurry to be 0.6L / min, and the rotation speed of the dispersion disc is 7000r / min, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Single sided density | aaaaa | aaaaa |

| Bottom diameter | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com