Aviation engine labyrinth seal structure with tapered leading air holes

A technology of aero-engines and air-inducing holes, which is applied in the direction of engine components, machines/engines, gas turbine devices, etc., can solve the problems of improving the sealing effect, and achieve the effects of reducing leakage, reducing leakage, and increasing circumferential flow damping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

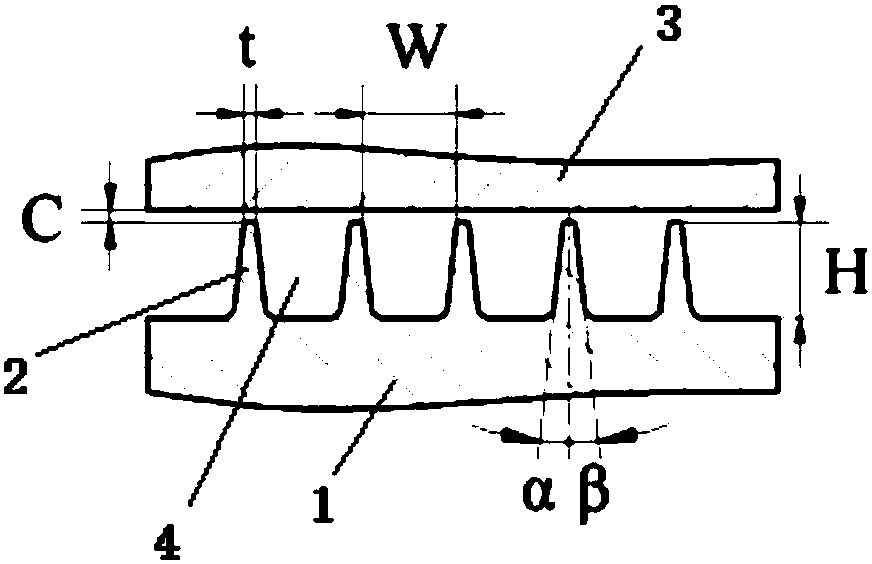

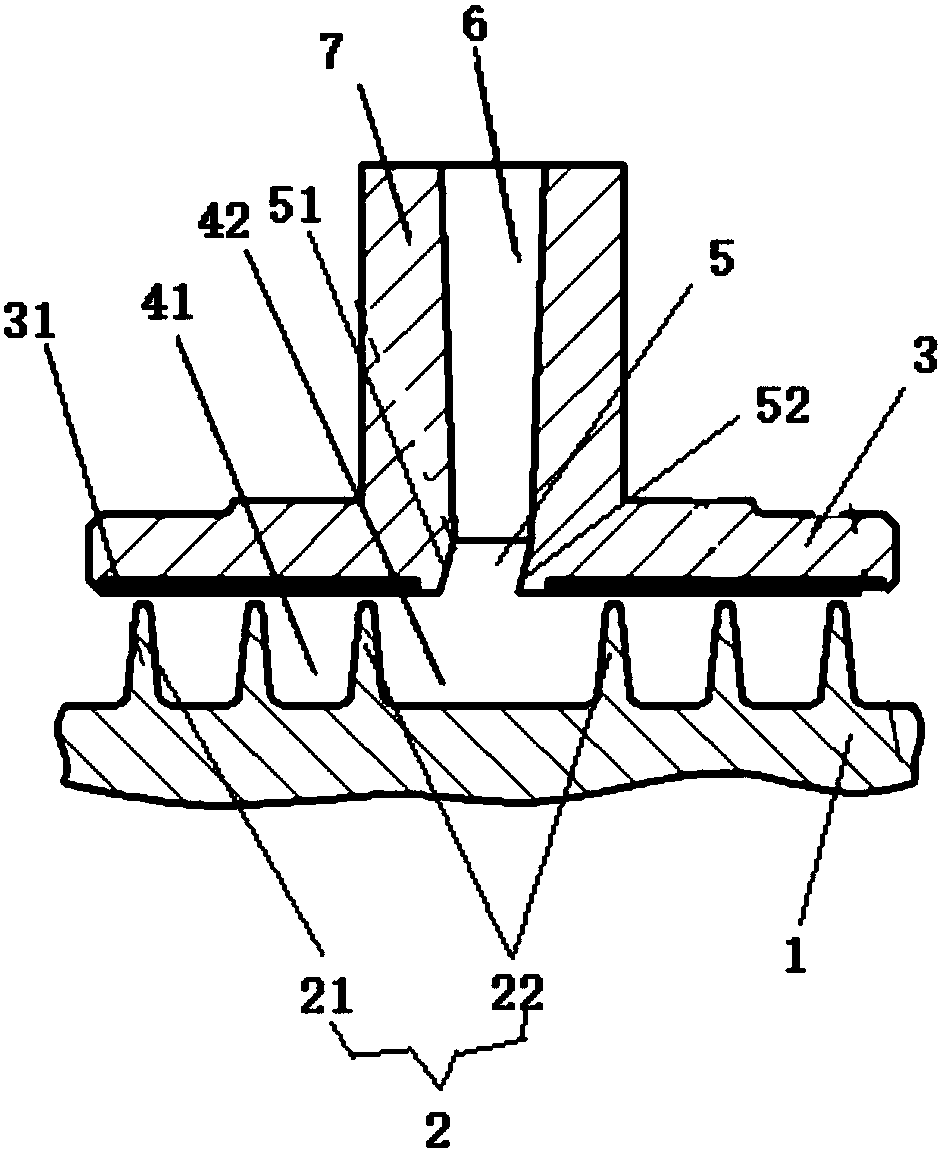

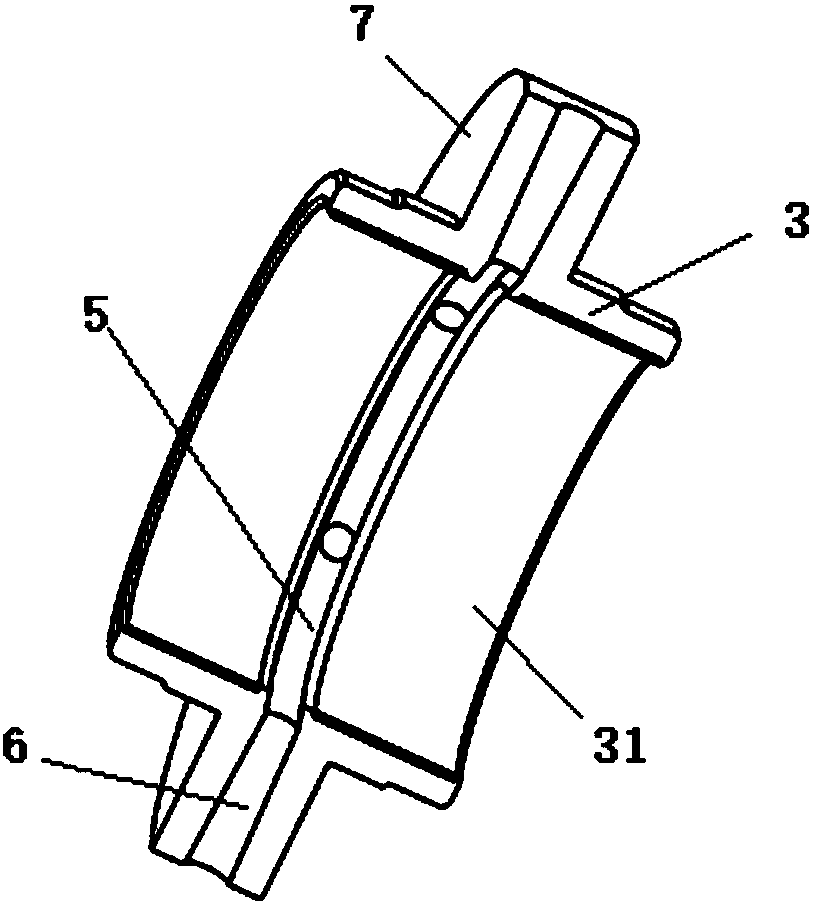

[0019] Example 1 as Figure 2 to Figure 4 As shown, the aero-engine grate seal structure with tapering air-introduction holes in this embodiment includes a rotating shaft 1 and a grate bushing ring 3. The rotating shaft 1 is provided with 6 sections of grate teeth 2, and the first one of them is arranged according to the flow direction of the airflow. The 1st, 2nd, 5th, and 6th grate teeth are the end grate teeth 21, and the 3rd and 4th grate teeth are the central grate teeth 22; Strict clearance C is not more than 0.5mm, between the 1st section and the 2nd section, between the 2nd section and the 3rd section, between the 4th section and the 5th section, The tooth distance W between the 5th section and the 6th section is the same to form a vortex cavity 41 of the same size; the tooth distance between the 3rd section and the 4th section is the 5th section 2.15 times of the tooth pitch between the teeth and the 6th section grate teeth, so that a wider central bleed air tooth ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com