Self-supporting indium film with mass thickness ranging from 600 to 1200 mu g/cm<2> and its preparation method thereof

A quality thickness, self-supporting technology, applied in the direction of ion implantation plating, coating, metal material coating process, etc., can solve problems such as poor flatness, cracks in Ir deposition layer, target film curling, etc., and achieve the effect of avoiding cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

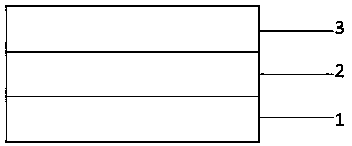

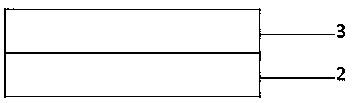

[0044] A mass thickness of 800μg / cm 2 The preparation method of self-supporting indium thin film, comprises the following steps: select the glass of 2cm * 2cm * 0.5cm as substrate 1, adopt electron beam thermal evaporation method to deposit sodium chloride release agent 2, described sodium chloride release agent 2 Thickness 250nm;

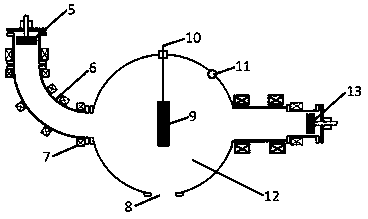

[0045] The glass substrate 1 is placed on the workpiece table 9, the zinc oxide target is used as the 90-degree FCVA cathode 5, and the indium target is used as the straight tube FCVA cathode 13, and the deposition device is evacuated through the vacuum port 8, so that the inside of the reaction chamber 12 Vacuum degree is 1.0×10 -4 Pa; then pass into argon gas from the inlet 11, so that the vacuum degree in the reaction chamber 12 is 2Pa; open the 90-degree magnetic filter cathode vacuum arc (FCVA) system and set the deposition parameters as: the arc starting current is 60A, and the magnetic field of the elbow 1.0A, beam current 40mA, negative b...

Embodiment 2

[0050] A mass thickness of 1000μg / cm 2 The preparation method of the self-supporting indium thin film comprises the following steps: selecting 2cm×2cm×0.5cm single crystal silicon as the substrate 1, adopting the electron beam thermal evaporation method to deposit the sodium chloride release agent 2, and the sodium chloride release agent The thickness of the agent 2 is 230nm; the monocrystalline silicon substrate 1 is placed on the workpiece table 9, the zinc oxide target is used as the 90-degree FCVA cathode 5, and the indium target is used as the straight tube FCVA cathode 13, and the deposition device is pumped through the vacuum port 8. Vacuum, so that the degree of vacuum in the reaction chamber 12 is 1.5 × 10 -4Pa; then pass argon gas from the air inlet 11, so that the vacuum degree in the reaction chamber 12 is 1.5Pa; open the 90-degree magnetic filter cathode vacuum arc (FCVA) system and set the deposition parameters as follows: the arc starting current is 70A, the elb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com