Environment-friendly flame-retardant polystyrene composite material and preparing method thereof

A polystyrene and composite material technology, applied in the field of polystyrene composite materials and their preparation, can solve the problems of reduced impact strength, easy yellowing, easy decomposition of flame retardants, etc. Effect

Active Publication Date: 2019-01-04

WUHAN JINFA TECH CO LTD +1

View PDF5 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The flame retardants commonly used in environmentally friendly flame-retardant PS systems have the disadvantages of easy decomposition and yellowing, which limits their use in light-colored products

At the same time, the addition of flame retardants will lead to a decrease in some physical properties, especially the notched impact strength, which needs to be toughened

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

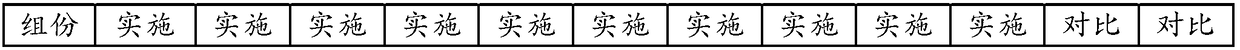

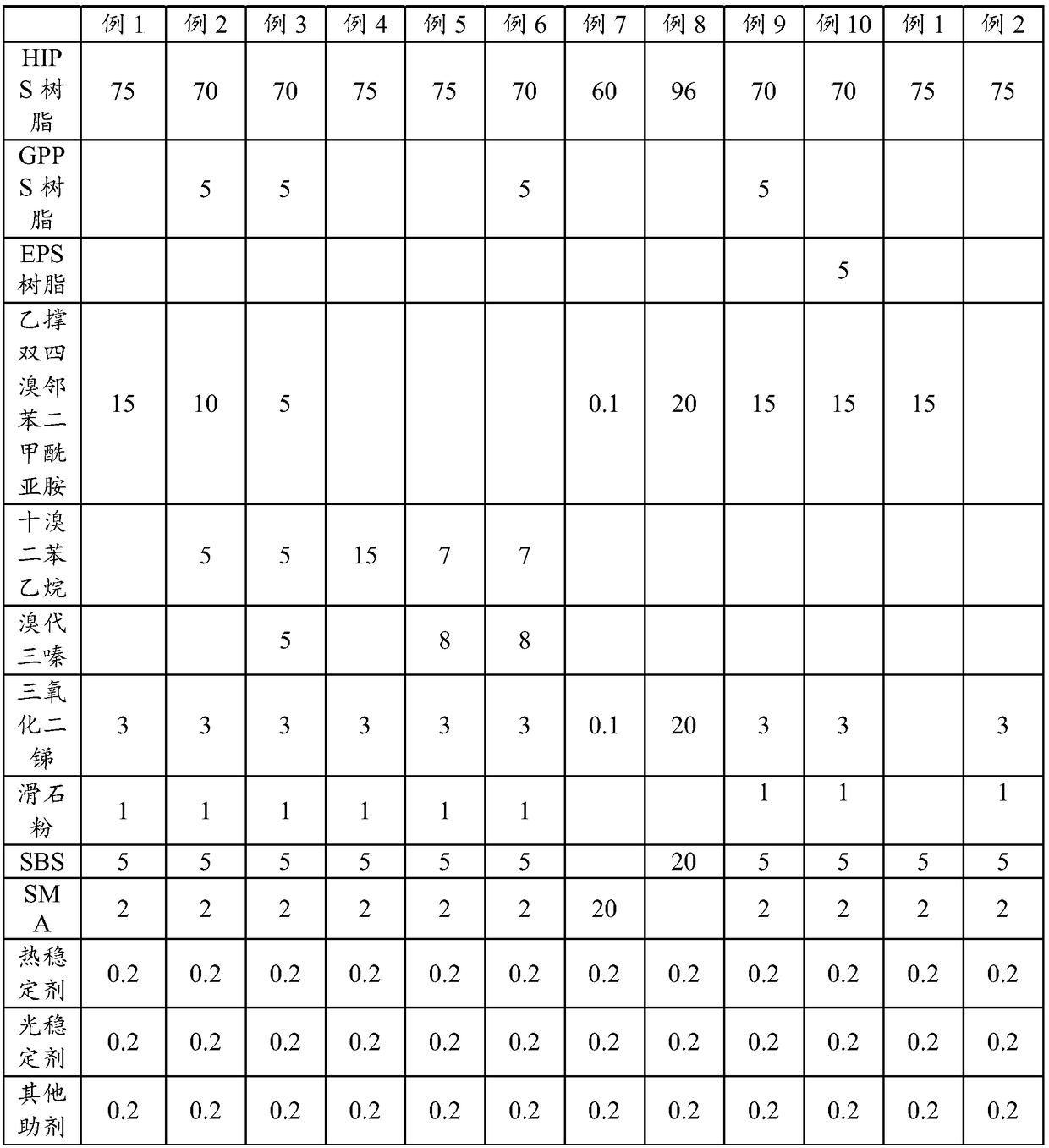

[0021] In order to better illustrate the purpose, technical solutions and advantages of the present invention, the present invention will be further described below in conjunction with specific examples.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses an environment-friendly flame-retardant polystyrene composite material. The environment-friendly flame-retardant polystyrene composite material is prepared from, by weight, 60-96 parts of PS resin, 0.1-20 parts of a fire retardant and 0.1-20 parts of a flame retardant synergist, wherein the fire retardant is at least one of decabromodiphenyl ethane, brominated epoxy resin,tri cyanurate, ethylene ditetrabromo-phthalic imide, tetrabromo bisphenol A and eight bromo ether; the flame retardant synergist is at least one of antimonous oxide and talcum powder. In the environment-friendly flame-retardant polystyrene composite material, through the synergistic interaction effect of the fire retardant and the flame retardant synergist, the composite material has the good flame resistance; as a compatilizer and a toughening agent are added, the composite material has the good yellowing resistance and toughness. The invention also discloses a preparing method for the environment-friendly flame-retardant polystyrene composite material.

Description

technical field [0001] The invention relates to a polystyrene composite material and a preparation method thereof, in particular to an environment-friendly flame-retardant polystyrene composite material and a preparation method thereof. Background technique [0002] In today's society, the requirements for fire safety of materials are getting higher and higher. Since the combustion of commonly used flame retardants such as decabromodiphenyl ether produces a large amount of black smoke, and even the generation of strong carcinogen dioxin, which causes great harm to the human body, laws and regulations are generally issued in various countries to restrict certain flame retardants. usage of. In areas such as household appliances, there is a risk of short-circuit fire due to contact with electricity, so materials are required to be flame-retardant. [0003] The flame retardants commonly used in environmentally friendly flame-retardant PS systems have the disadvantages of easy ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L25/06C08L51/04C08L63/00C08L53/02C08L35/06C08K13/02C08K5/03C08K5/3492C08K5/136C08K3/22C08K3/34

CPCC08L25/06C08L51/04C08L2201/02C08L2205/03C08L63/00C08L53/02C08L35/06C08K13/02C08K5/03C08K5/3492C08K5/136C08K3/2279C08K3/34

Inventor 王扬利杨磊李其龙何浏炜周英辉余启生孙华旭

Owner WUHAN JINFA TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com