System for treating high-concentration VOCs gas and workflow thereof

A high-concentration, gas-based technology, applied in gas treatment, air quality improvement, membrane technology, etc., to achieve mild reaction conditions, high processing efficiency, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

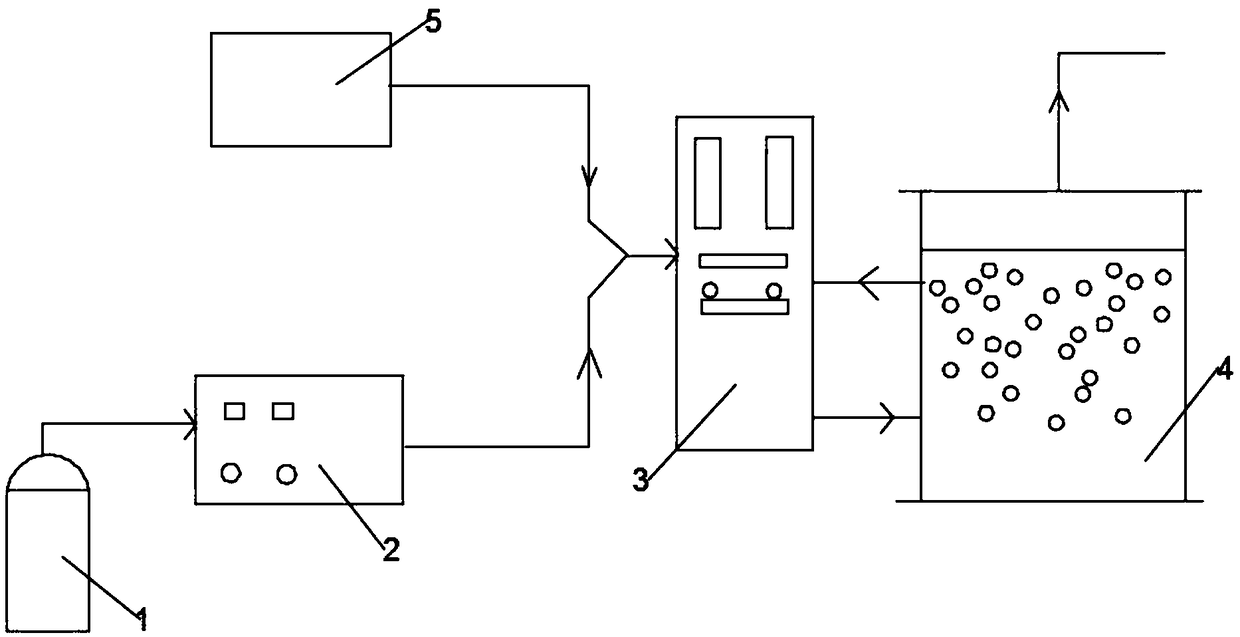

[0021] A system for processing high-concentration VOCs gas, comprising an ozone generator 2, a microbubble generator 3 and a reactor 4, the inlet of the ozone generator 2 is connected to the outlet of the oxygen cylinder 1, and the outlet of the ozone generator 2 is connected to the outlet of the oxygen cylinder 1. The microbubble generator 3 is connected, and the water outlet / air port of the microbubble generator 3 is connected with the bottom of the reactor 4 and the reactor 4 adopts a closed structure, and the top of the reactor 4 is provided with a tail gas discharge pipe. The ozone generator 2 adopts an oxygen generator.

[0022] The working process of the system for processing high-concentration VOCs gas, the specific steps are as follows:

[0023] Step 1, the oxygen cylinder sends oxygen to the ozone generator, the ozone generator uses oxygen as the gas source to generate ozone gas, and the ozone gas enters the micro-bubble generator to generate ozone micro-bubbles;

...

Embodiment 2

[0027] A system for processing high-concentration VOCs gas, comprising an ozone generator 2, a microbubble generator 3 and a reactor 4, the inlet of the ozone generator 2 is connected to the outlet of the oxygen cylinder 1, and the outlet of the ozone generator 2 is connected to the outlet of the oxygen cylinder 1. The microbubble generator 3 is connected, and the water outlet / air port of the microbubble generator 3 is connected with the bottom of the reactor 4 and the reactor 4 adopts a closed structure, and the top of the reactor 4 is provided with a tail gas discharge pipe. The microbubble generator 3 adopts an OHR gas-liquid mixing tube generator.

[0028] The working process of the system for processing high-concentration VOCs gas, the specific steps are as follows:

[0029] Step 1, the oxygen cylinder sends oxygen to the ozone generator, the ozone generator uses oxygen as the gas source to generate ozone gas, and the ozone gas enters the micro-bubble generator to generat...

Embodiment 3

[0033] A system for processing high-concentration VOCs gas, comprising an ozone generator 2, a microbubble generator 3 and a reactor 4, the inlet of the ozone generator 2 is connected to the outlet of the oxygen cylinder 1, and the outlet of the ozone generator 2 is connected to the outlet of the oxygen cylinder 1. The microbubble generator 3 is connected, and the water outlet / air port of the microbubble generator 3 is connected with the bottom of the reactor 4 and the reactor 4 adopts a closed structure, and the top of the reactor 4 is provided with a tail gas discharge pipe. The inside of the reactor 4 is coated with an anti-corrosion layer and the inside of the reactor 4 is provided with an aqueous medium.

[0034] The working process of the system for processing high-concentration VOCs gas, the specific steps are as follows:

[0035] Step 1, the oxygen cylinder sends oxygen to the ozone generator, the ozone generator uses oxygen as the gas source to generate ozone gas, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com