A high -performance Co3O4-CeO2/Co-N-C composite catalyst and preparation method and application thereof

A co3o4-ceo2, composite catalyst technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of poor activity of non-precious metal catalysts, complex preparation process, etc., and achieve excellent ORR and OER catalytic performance. The process is simple and easy. effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

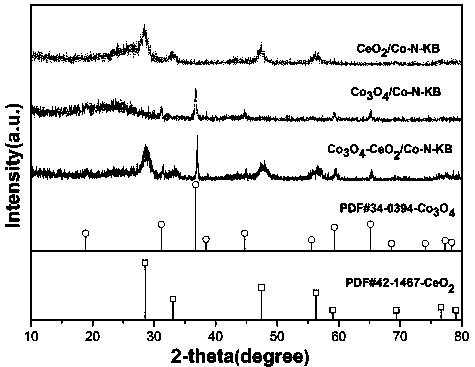

[0048] This embodiment provides a high performance Co 3 o 4 -CeO 2 / Co-N-KB composite catalyst, prepared by the following method.

[0049] To prepare N-KB (nitrogen-doped carbon carrier), weigh 7 grams of KB carbon (Ketjenblack carbon) and 7 grams of melamine and drop them into a 250ml beaker, add 200ml of ethanol, heat and stir at 60°C for 8 hours, evaporate the ethanol and dry Dry. After drying, grind it for later use, and name it N-KB.

[0050] Then weigh 0.25g of cobalt acetate and 0.15g of cerium nitrate, add them into a 100ml beaker, dissolve in 70ml of deionized water, adjust the pH to 8.0 with sodium bicarbonate, then add 1g of N-KB, and heat and stir at 80°C 30 minutes. Then add it into a 100ml polytetrafluoroethylene liner, and conduct a hydrothermal reaction at a constant temperature of 150°C for 12 hours. After the reaction, it was filtered and washed several times. After drying and grinding, the sample was calcined in a muffle furnace at 300 °C for 2 h, and...

Embodiment 2

[0061] This embodiment provides a high performance Co 3 o 4 -CeO 2 / Co-N-KB composite catalyst, prepared by the following method.

[0062] To prepare N-KB, weigh 5 grams of KB carbon and 5 grams of melamine and drop them into a 250ml beaker, add 150ml of ethanol, heat and stir at 80°C for 8 hours, evaporate the ethanol and dry it. After drying, grind it for later use, and name it N-KB.

[0063] Then weigh 0.25g of cobalt sulfate and 0.20g of cerium sulfate, add them to a 100ml beaker, and dissolve 70ml of deionized water, adjust the pH to 8.0 with ammonia water, then add 1g of N-KB, heat and stir at 80°C for 30 minutes . Then add it into a 100ml polytetrafluoroethylene liner, and conduct a hydrothermal reaction at a constant temperature of 140°C for 16 hours. After the reaction, it was filtered and washed several times. After drying and grinding, the sample was calcined in a muffle furnace at 200 °C for 4 h, and then ground to obtain Co 3 o 4 -CeO 2 / Co-N-KB composite ...

Embodiment 3

[0066] This embodiment provides a high performance Co 3 o 4 -CeO 2 / Co-N-KB composite catalyst, prepared by the following method.

[0067] To prepare N-KB, weigh 3 grams of KB carbon and 5 grams of melamine and drop them into a 250ml beaker, add 100ml of ethanol, heat and stir at 90°C for 9 hours, then evaporate the ethanol and dry it. After drying, grind it for later use, and name it N-KB.

[0068] Then weigh 0.25g of cobalt chloride and 0.15g of cerium chloride, add them to a 100ml beaker, and dissolve them in 70ml of deionized water, adjust the pH to 9.0 with sodium hydroxide, then add 1g of N-KB, at 80°C Heat and stir for 30 minutes. Then add it into a 100ml polytetrafluoroethylene liner, and conduct a hydrothermal reaction at a constant temperature of 160°C for 14 hours. After the reaction, it was filtered and washed several times. After drying and grinding, the sample was calcined in a muffle furnace at 300 °C for 3 h, and then ground to obtain Co 3 o 4 -CeO 2 / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com