Preparation method of modified nanometer calcium carbonate for ink

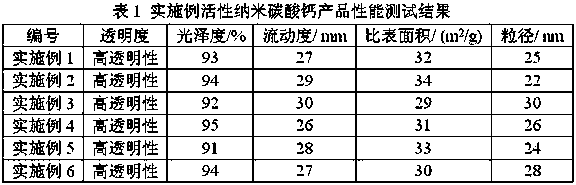

A nano-calcium carbonate, modified technology, applied in the direction of calcium carbonate/strontium/barium, ink, nanotechnology, etc., can solve the problems of large particle size of nano-calcium carbonate, poor compatibility of ink base materials, poor dispersion performance, etc. , to achieve the effect of good gloss and transparency, less product impurities and good application performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A preparation method for modified nano-calcium carbonate for ink, comprising the following steps:

[0025] 1) Add a crystal form control agent to the calcium hydroxide suspension with a mass fraction of 12%, and at 20°C, pass through carbon dioxide with a volume concentration of 55% for carbonization reaction. When the carbonization rate reaches 30%, add a crystallization aid agent, carbonization reaction 25min, the pH value of the system is 6.5, the carbonization reaction is finished, and the slurry containing nano-calcium carbonate is obtained; the crystal form control agent is sucrose, and the addition amount of the crystal form control agent is 0.6% of the calcium hydroxide mass; It is made by mixing sodium tripolyphosphate, sodium lignosulfonate and tall oil in a mass ratio of 1:2:1, and the amount of crystal aid added is 1% of the mass of calcium hydroxide;

[0026] 2) At 75°C, add the modified solution to the slurry containing nano-calcium carbonate in step 1), a...

Embodiment 2

[0029] A preparation method for modified nano-calcium carbonate for ink, comprising the following steps:

[0030] 1) Add a crystal form control agent to the calcium hydroxide suspension with a mass fraction of 11%, and at 18°C, pass through carbon dioxide with a volume concentration of 65% for carbonization reaction. When the carbonization rate reaches 30%, add a crystallization aid agent, carbonization reaction 20min, the pH value of the system is 6.6, the carbonization reaction ends, and the slurry containing nano-calcium carbonate is obtained; the crystal form control agent is lactose, and the addition amount of the crystal form control agent is 0.7% of the calcium hydroxide mass; It is made by mixing sodium tripolyphosphate, sodium lignosulfonate and tall oil in a mass ratio of 1:3:2, and the amount of crystal aid added is 1.2% of the mass of calcium hydroxide;

[0031] 2) At 70°C, add the modified solution to the slurry containing nano-calcium carbonate in step 1), and st...

Embodiment 3

[0034] A preparation method for modified nano-calcium carbonate for ink, comprising the following steps:

[0035] 1) Add a crystal form control agent to the calcium hydroxide suspension with a mass fraction of 10%, and at 21°C, pass through carbon dioxide with a volume concentration of 75% for carbonization reaction. When the carbonization rate reaches 30%, add a crystallization aid , carbonization reaction 18min, system pH value is 6.7, and carbonization reaction finishes, and the slurry containing nano-calcium carbonate is obtained; Crystal form control agent is beet sugar, and the addition amount of crystal form control agent is 0.5% of calcium hydroxide mass; It is made by mixing sodium tripolyphosphate, sodium lignosulfonate and tall oil in a mass ratio of 1:4:2, and the amount of crystal aid added is 1.3% of the mass of calcium hydroxide;

[0036] 2) At 85°C, add the modified solution to the slurry containing nano-calcium carbonate in step 1), and stir and mix for 2.5 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com