Self-repairing polyurethane, and preparation method and self-repairing method thereof

A self-healing and polyurethane technology, applied in the field of self-healing polyurethane and its preparation, can solve the problems of limited repair times, changes in material properties, and difficulty in realization, and achieve the effects of high self-healing efficiency, excellent mechanical properties, and high self-repairing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

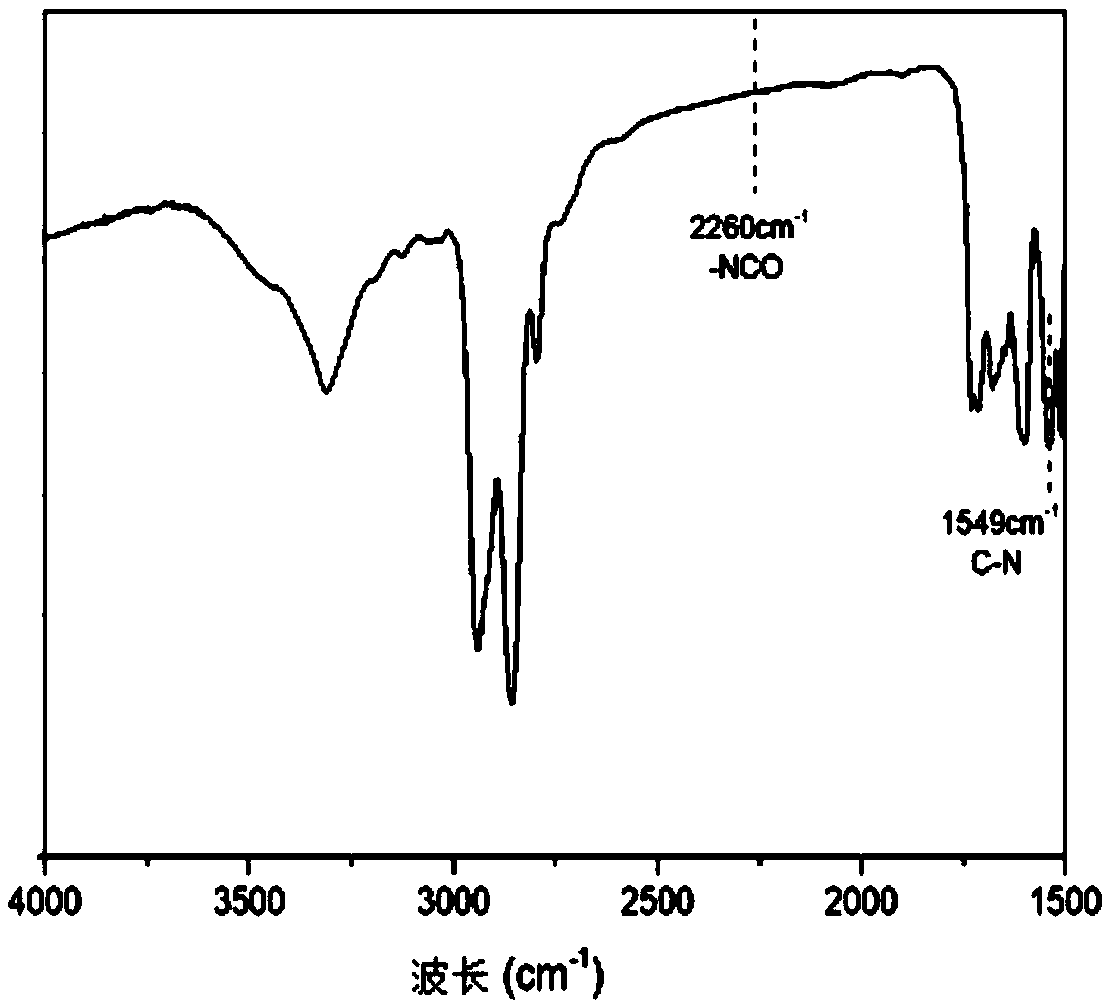

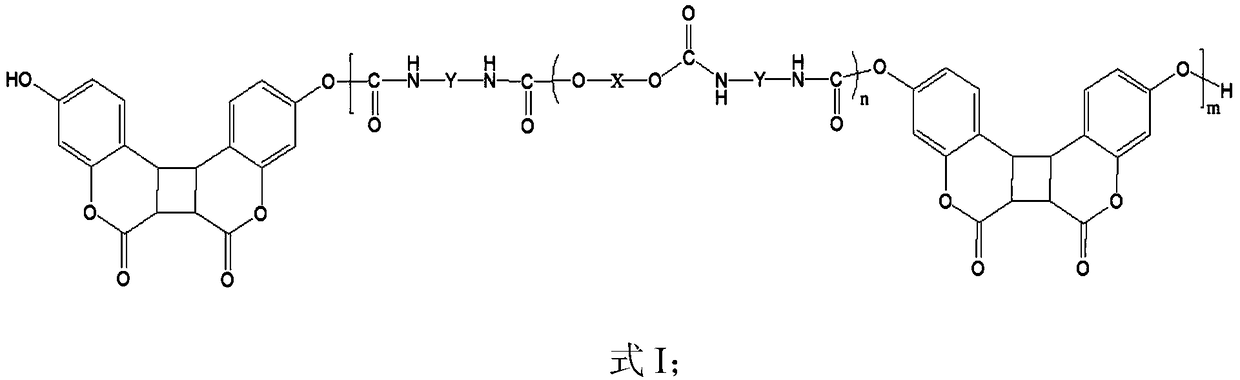

[0062] A preparation method of self-healing polyurethane is as follows:

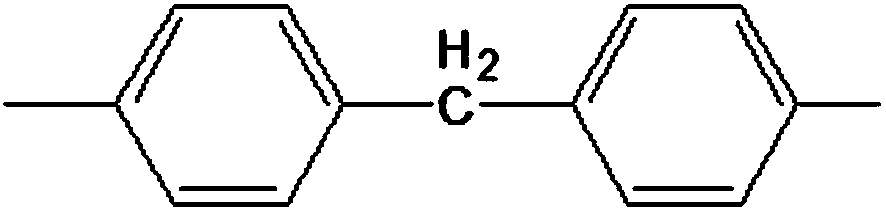

[0063] (1) Add a solution of polytetrahydrofuran (Mn=2000) with a concentration of 0.20 g / mL dropwise at a rate of 1 mL / min to 4,4'-methylenebis(isocyanate) with a concentration of 0.10 g / mL phenyl ester) solution, the prepolymerization reaction was carried out at 80°C, the stirring rate during the reaction was 200r / min, and the prepolymer mixture was obtained, in which, 4,4'-methylene bis(phenylisocyanate ) and the mol ratio of polytetrahydrofuran are 2:1;

[0064] (2) The 4-methylumbelliferone solution is irradiated with ultraviolet light at a wavelength of 360nm for 15min cross-linking to obtain a dimer solution of 4-methylumbelliferone, wherein the 4-methylumbelliferone and step (1) The molar ratio of 4,4'-methylenebis(phenylisocyanate) is 1:1;

[0065] (3) The dimer solution obtained in step (2) is added dropwise to the prepolymer mixed solution obtained in step (1) with a rate of addition of 1mL / ...

Embodiment 2-8

[0067] The only difference from Example 1 is that in this example, the molar ratio of 4,4'-methylene bis(phenylisocyanate) to polytetrahydrofuran is 2.1:1 (Example 2), 1.8:1 (embodiment 3), 2.3:1 (embodiment 4);

[0068] The only difference from Example 1 is that in this example, the molar ratio of 4-methylumbelliferone to step (1) 4,4'-methylenebis(phenylisocyanate) is 1.1:1 (Example 5), 1.05:1 (Example 6), 0.8:1 (Example 7), 1.3:1 (Example 8).

Embodiment 9-10

[0070] The only difference from Example 1 is that in this example, in step (1), the polytetrahydrofuran solution is directly mixed with the 4,4'-methylenebis(phenylisocyanate) solution and then prepolymerized (Embodiment 9);

[0071] The only difference from Example 1 is that in this example, in step (3), the dimer is directly mixed with the prepolymer mixture and then polymerized (Example 10).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com