High-strength self-repairing polyurethane material and preparation method thereof

A polyurethane material and self-healing technology, applied in the fields of coatings, flexible electronics, and synthetic rubber, can solve problems such as poor reactivity, high reaction temperature, and poor toughness, and achieve the effect of easy reprocessing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

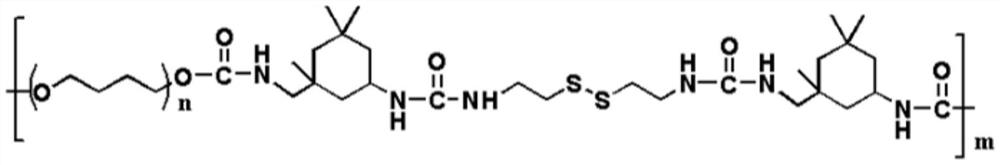

[0031] Preparation method of the present invention (taking cystamine as example, see attached figure 1 ):

[0032] Put 100 parts by mass of IPDI into the reactor, add 0.3-0.7 parts of low molecular weight PTMEG in molar ratio, heat up to 75°C for 2 hours, add cystamine in molar ratio of 0.75-0.35 parts, water bath (12-18°C), ultrasonic , mechanical stirring (300 ~ 500r / min), N 2 The polymer of the present invention can be obtained after reacting for 4 hours under protection.

Embodiment 1

[0034] Add PTMEG-1000 (15g), IPDI (6.67g), DBTDL (0.08g) into a 500mL three-neck flask, add 5mLN,N-dimethylacetamide (DMAc) to dissolve the reactants, and put them at 75°C under N 2 Under the atmosphere, mechanically stirred for 2 hours to obtain a colorless solution, which was a prepolymer. After obtaining the prepolymer, the three-necked flask was placed in a water bath and cooled to 15°C, and the chain extender cystamine (2.29g) dissolved in 160mL DMAc was added dropwise to the container, and heated under N 2 After mechanically stirring for 4 hours under the atmosphere, a colorless, transparent and viscous DMAc solution of self-healing polyurethane was obtained, and the self-healing polyurethane could be obtained after drying. The self-healing polyurethane has a tensile strength of 37.1MPa, an elongation at break of 1080%, and a light transmittance of 90%. The tensile strength can recover 96.8% after being treated at 80°C for 4 hours.

Embodiment 2

[0036] PTMEG-1000 (15g), IPDI (6.67g), DBTDL (0.08g) were added in a 500mL three-necked flask, and 5mLDMAc was added to dissolve the reactant, and at 75°C, N 2 Under the atmosphere, mechanically stirred for 2 hours to obtain a colorless solution, which was a prepolymer. After obtaining the prepolymer, the three-neck flask was placed in a water bath and cooled to 15 ° C, and the chain extender 3,3-dithiodipropylamine (2.71 g) dissolved in 160 mL of DMAc was added dropwise to the container, and in N 2After mechanically stirring for 4 hours under the atmosphere, a colorless, transparent and viscous DMAc solution of self-healing polyurethane was obtained, and the self-healing polyurethane could be obtained after drying. The self-healing polyurethane has a tensile strength of 33.75MPa, an elongation at break of 1146%, and a light transmittance of 89%. The tensile strength can recover 95.4% after being treated at 80°C for 4 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com