Technological method for recycling treatment of waste emulsified liquid

A technology of waste emulsion and process method, applied in chemical instruments and methods, special compound water treatment, filtration treatment, etc., can solve the problems of membrane damage, waste of resources, inability to reuse, etc., to prevent the precipitation of leachate, reduce The effect of running costs and reducing disposal costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

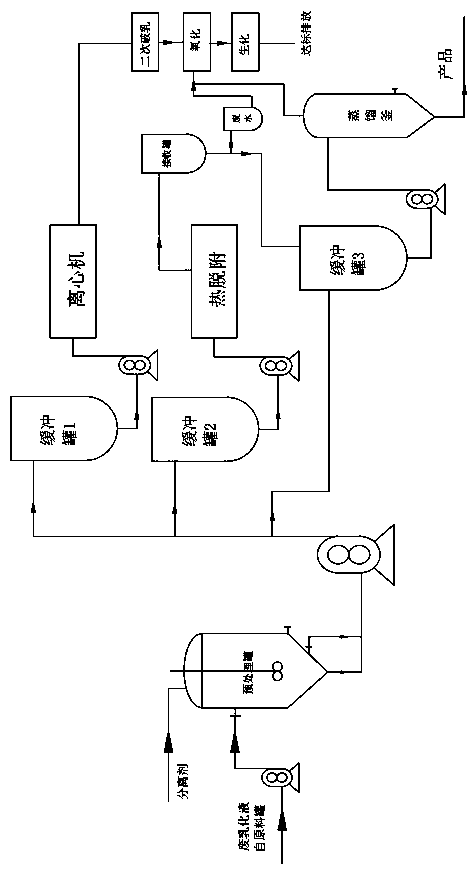

Image

Examples

Embodiment 1

[0024] Taking the waste emulsion produced by an aluminum processing enterprise as an example, its basic composition is about 55% water, about 25% oil phase, and about 20% slag. The specific disposal process is as follows:

[0025] 1. The raw material waste emulsion is sent to the pretreatment tank after passing through the pump and double cylinder filter, and it is heated to 80°C, stirred, and a certain proportion of separating agent (separating agent adopts sulfuric acid) is added at the same time, and the dosage is 1% of the waste emulsion. 1.5%, to achieve preliminary separation of oil, water and slag;

[0026] 2. After pretreatment, the lower layer is water and a small amount of slag, the middle mixture, and the upper layer is oil. The lower layer is pumped to the buffer tank 1, the intermediate mixture is sent to the buffer tank 2, and the upper layer oil is sent to the buffer tank 3.

[0027] 3. The water slag in the buffer tank 1 is pumped to the decanter centrifuge fo...

Embodiment 2

[0035] Take the waste emulsion produced by an aluminum processing enterprise as an example. Its basic composition is about 30% water, about 40% oil phase, and about 30% slag. The specific disposal process is as follows:

[0036] 1. The raw material waste emulsion is sent to the pretreatment tank after passing through the pump and double-tube filter, and it is heated to 60°C, stirred, and at the same time, a separating agent is added (separating agent adopts sulfuric acid and ferric chloride), and the dosage is the mass of the waste emulsion 0.5% of the oil, to achieve the preliminary separation of oil, water and slag;

[0037] 2. After pretreatment, the lower layer is water and a small amount of slag, the middle mixture, and the upper layer is oil. The lower layer material is pumped to the buffer tank 1, the intermediate mixture is sent to the buffer tank 2, and the upper layer oil is sent to the buffer tank 3;

[0038] 3. The water slag in the buffer tank 1 is pumped to the ...

Embodiment 3

[0044] Take the waste emulsion produced by an aluminum processing enterprise as an example. Its basic composition is about 55% water, about 15% oil phase, and about 50% slag. The specific disposal process is as follows:

[0045] 1. The raw material waste emulsion is sent to the pretreatment tank after passing through the pump and double-tube filter, and it is heated to 80°C, stirred, and at the same time, a separating agent is added (separating agent adopts sulfuric acid and ferric chloride), and the dosage is the mass of the waste emulsion 1% of the oil, to achieve the preliminary separation of oil, water and slag;

[0046] 2. After pretreatment, the lower layer is water and a small amount of slag, the middle mixture, and the upper layer is oil. The lower layer material is pumped to the buffer tank 1, the intermediate mixture is sent to the buffer tank 2, and the upper layer oil is sent to the buffer tank 3;

[0047] 3. The water slag in the buffer tank 1 is pumped to the deca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com