Safe and efficient type ketone-containing organic exhaust gas adsorbent

An organic waste gas, high-efficiency technology, applied in gas treatment, membrane technology, other chemical processes, etc., can solve problems affecting the quality of recovered solvents, achieve good industrial application prospects, cheap raw materials, and increase the ignition temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of the safe and efficient ketone-containing organic waste gas adsorbent specifically includes the following steps:

[0031] A) Preparation and pretreatment of honeycomb activated carbon: select wooden activated carbon and prepare honeycomb activated carbon with a size of (40-60)mm×(40-60)mm×(80-120)mm, and put it as a carrier After fully washing in ionized water, blow off the remaining liquid in the pores with compressed air, and then dry overnight in a drying device with nitrogen at 100-120℃ to remove water vapor and other adsorbed impurities, and cool at room temperature for later use;

[0032] B) Alkaline nitride impregnation: Weigh the alkaline nitride in a container, and immerse the pretreated honeycomb activated carbon in the alkaline nitride. The solid-to-liquid ratio of honeycomb activated carbon to alkaline nitride is 20-40g / 200ml, sealed container, put it in a 45-55℃ water bath, shake for 0.5-1.5h, take it out, wash thoroughly with deionized...

Embodiment 1

[0050] Take and prepare honeycomb activated carbon F 1 30g, as a carrier, put into deionized water to wash thoroughly, blow off the remaining liquid in the pores with compressed air, and then dry overnight in an oven with nitrogen at 110°C to remove water vapor and other adsorbed impurities, cool at room temperature for later use, weighing marked as F 2 ;

[0051] Weigh 200ml of ethylenediamine into the flask, and put the pretreated F 2 Immerse in the flask and close the sealing plug. Put it in a 50℃ water bath, shake for 1h, take out F 2 After fully washing with deionized water, blow off the remaining liquid in the pores with compressed air, and then dry overnight in a 100-120 ℃ nitrogen oven to remove water vapor and other adsorbed impurities, and cool at room temperature for later use. Repeat the above steps twice, the weighing is marked as F 3 ;

[0052] Weigh 50g of indole and dissolve it in 200ml ethanol solution, put it in a 600ml flask, and then mark F 3 The adsorbent is ...

Embodiment 2

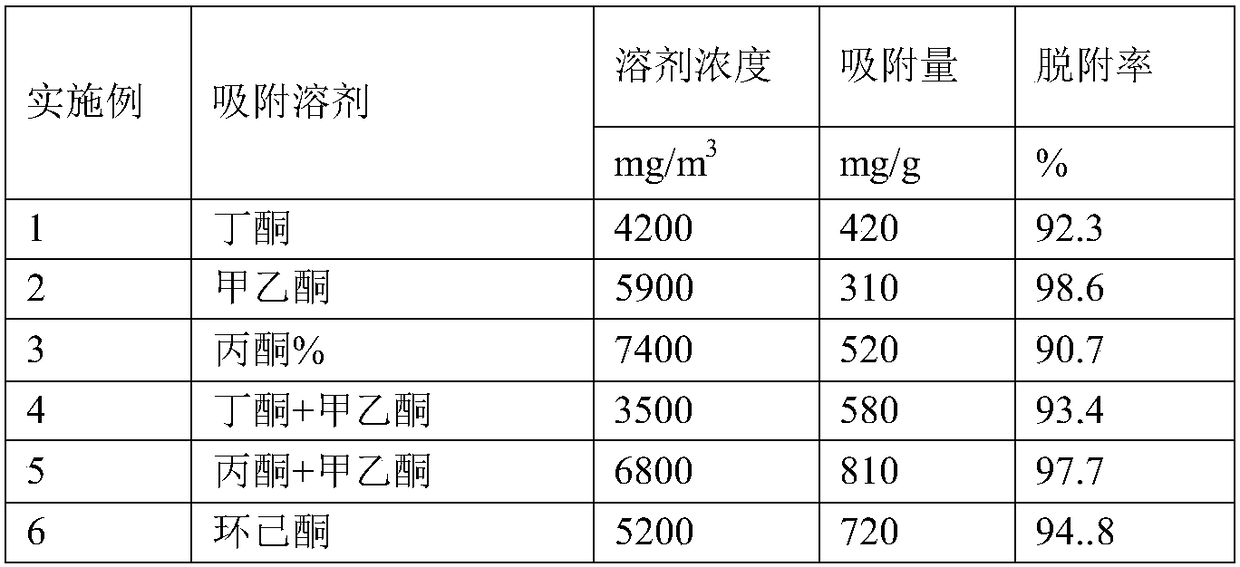

[0055] Same as Example 1, the basic nitride is aniline, repeat once; the neutral nitride carbazole, repeat 3 times, take the above-mentioned adsorbent and put it in a quartz tube, and pour in nitrogen gas to seal it, then put it in the microwave oven Give microwave irradiation, and make the temperature rise rapidly to 600°C, microwave irradiation for 2 min, and cooling to obtain modified adsorbent. The mass percentage of each component is about 81% of honeycomb activated carbon, about 11% of aniline, and about 8% of carbazole. According to the adsorbent evaluation method of the present invention, the adsorption and desorption performance are tested. The corresponding evaluation conditions and reaction results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com