Waterproof roll and preparation method thereof

A waterproofing membrane and additive technology, applied in the direction of fiber type, textile and papermaking, fiber processing, etc., can solve the problems of weather resistance, poor aging resistance, poor mechanical properties, etc. Wear resistance, the effect of reducing the hydrogen bond ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

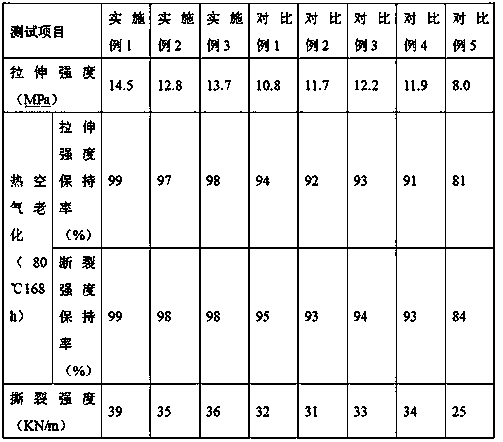

Examples

preparation example Construction

[0033] A preparation method of a waterproof coiled material, comprising the steps of:

[0034] A. In terms of parts by mass, take 100# asphalt and heat it up to 170~180°C and mix for 30~50 minutes, add 10# asphalt with 20~50% of the quality of 100# asphalt, stir and mix for 20~30 minutes, then add 100# asphalt 20~40% of the elastomer additive, stirred and mixed at 100~120°C for 1~3h to obtain the matrix;

[0035] B. According to the mass fraction, take 8~12 parts of modifier, 5~8 parts of anti-ultraviolet absorption additive, 1~4 parts of antioxidant, 20~30 parts of talcum powder, and stir and mix at 75~80°C for 1~3h , to obtain mixture b, take mixture b according to the mass ratio of 3~5:10~30, add the matrix and mix, stir and mix at 170~180°C for 40~50min, and obtain impregnating solution, take polyester felt and immerse in the impregnating solution, keep for 3~5min , take out the impregnated polyester felt, press it, and dry it to obtain the anti-coil material.

[0036] E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com