Long-acting anti-rust method and equipment for hot-rolled magnetic yoke steel

A yoke steel, long-term technology, applied in the field of hot rolling, can solve the problems of easy rust on the surface of yoke steel products, achieve good anti-rust effect, simple operation, and solve the effect of easy rust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

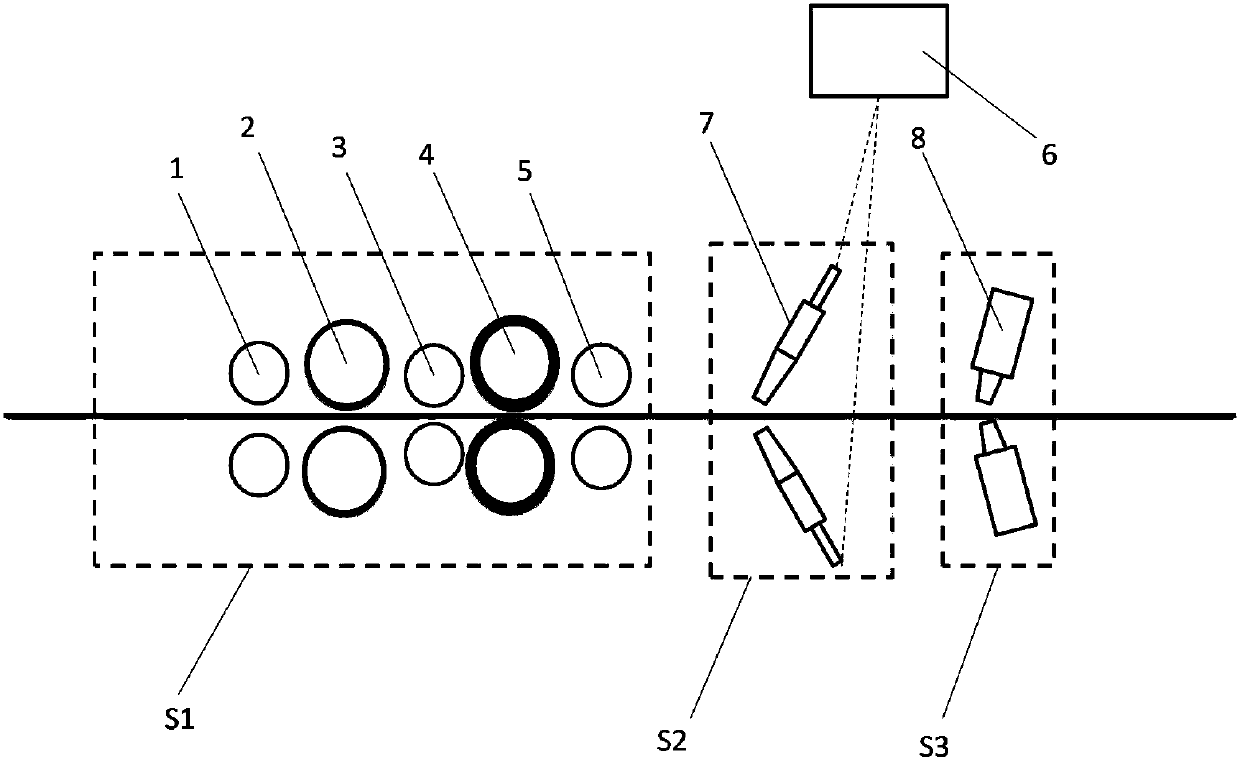

[0029] Such as figure 1 As shown, a long-term anti-rust equipment for hot-rolled yoke steel includes in sequence according to the moving direction of hot-rolled yoke steel: No. 1 pinch roller 1, upper and lower coarse brush rollers 2, No. 2 pinch roller 3, upper and lower fine brushes Roller 4, No. 3 pinch roller 5, antirust agent nozzle 7 and purge nozzle 8; in addition, an antirust agent liquid reservoir 6 is connected to the antirust agent nozzle 7.

[0030] There are two rows of antirust agent nozzles, which are respectively arranged on the upper and lower sides of the hot-rolled yoke steel, and the included angle between the nozzles and the moving direction of the hot-rolled yoke steel is 60°. The distance (shortest distance) between the two rows of nozzles is 35mm, and the injection pressure is 0.7Mpa.

[0031] The purging nozzles are in two rows, respectively arranged on the upper and lower sides of the hot-rolled yoke steel, and the included angle between the nozzles ...

Embodiment 2

[0044] A long-term anti-rust equipment for hot-rolled yoke steel includes: No. 1 pinch roller, upper and lower coarse brush rollers, No. 2 pinch roller, upper and lower fine brush rollers, and No. 3 pinch roller according to the moving direction of hot-rolled yoke steel Roller, anti-rust agent nozzle and blowing nozzle; in addition, a anti-rust agent reservoir is also provided to connect with the anti-rust agent nozzle.

[0045] The anti-rust agent nozzles are in two rows, respectively arranged on the upper and lower sides of the hot-rolled yoke steel, and the included angle between the nozzles and the moving direction of the hot-rolled yoke steel is 75°. The distance (shortest distance) between the two rows of nozzles is 38mm, and the injection pressure is 0.9Mpa.

[0046]The purging nozzles are in two rows, respectively arranged on the upper and lower sides of the hot-rolled yoke steel, and the included angle between the nozzles and the moving direction of the hot-rolled yok...

Embodiment 3

[0059] Embodiment 3 is substantially the same as Example 2, and the only difference is that the rust remover used is prepared by the following steps: 1) the preparation mass fraction is a 5.2% phosphoric acid solution; 2) adding citric acid and tannic acid in the phosphoric acid solution, After the addition, the concentration of citric acid is 230mg / L, the concentration of tannic acid is 265mg / L, and it is stirred for 35 minutes at a speed of 95 rpm; Add sodium tungstate dropwise. After the addition, the concentration of sodium tungstate is 490mg / L. After the dropwise addition, stir for 45 minutes at a stirring speed of 40 rpm; 4) Cool to room temperature to form a rust inhibitor.

[0060] After this process, the hot-rolled yoke steel starts to rust a little after 63 hours under the conditions of temperature 49°C and relative humidity 98%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| velocity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com