Adhesive having high glass-transition temperature and flexible copper-coated plate

A flexible copper clad laminate, transition temperature technology, used in adhesives, adhesive additives, polymer adhesive additives, etc., can solve the problem of heat resistance, chemical resistance, dimensional stability, long-term reliability can not meet the requirements of use, Problems such as limited heat resistance and low glass transition temperature, to achieve the effect of low cost, strong peeling performance, and excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] (1) Adhesive formula:

[0063] Polyetherimide resin (purchased from Saudi Basic Industries Corporation, SABIC): 20 parts by mass; HP-4700: 1 part by mass; JD-919: 8 parts by mass; DOPO: 3 parts by mass; SPH-100: 4 parts by mass ; CTBN: 2 parts by mass; 4,4'-DDS: 4 parts by mass; 2-ethyl-4 methylimidazole: 0.3 parts by mass; KBM-603: 0.3 parts by mass; solvent (dimethylformamide): 60 parts by mass.

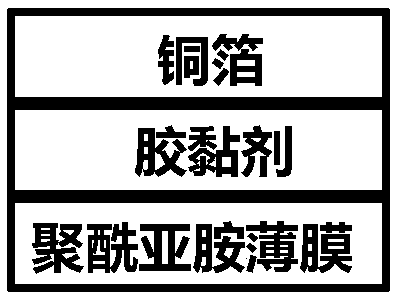

[0064] (2) Preparation method of flexible copper clad laminate:

[0065] The adhesive prepared by the above formula is coated on the polyimide film, dried in an oven at 100°C for 5 minutes, and then rolled and laminated with copper foil at 130°C to obtain a semi-cured composition;

[0066] The semi-cured composition was post-cured at 180° C. to obtain a single-sided flexible copper clad laminate.

[0067] In the flexible copper clad laminate, the adhesive layer has a thickness of 15 microns; the polyimide film has a thickness of 25 microns; and the copper foil is an elect...

Embodiment 2

[0081] (1) Adhesive formula:

[0082] Polyetherimide resin (purchased from Saudi Basic Industries Corporation, SABIC): 20 parts by mass; HP-4700: 3 parts by mass; XD-1000: 6 parts by mass; DOPO: 3.5 parts by mass; SPH-100: 3.5 parts by mass ; CTBN: 2.1 parts by mass; 4,4'-DDS: 3.8 parts by mass; 2-ethyl-4 methylimidazole: 0.32 parts by mass; KBM-603: 0.28 parts by mass; solvent (dimethylformamide): 60 parts by mass.

[0083] (2) According to the preparation method of Example 1, a flexible copper clad laminate was prepared.

[0084] (3) Carry out performance test to described flexible copper-clad laminate according to the test method of embodiment 1:

[0085] Table 2 Performance measurement results of flexible copper clad laminates

[0086]

Embodiment 3

[0088] (1) Adhesive formula:

[0089] Polyamide-imide resin (Vylomax, purchased from Japan Toyobo Co., Ltd.): 21 parts by mass; HP-4700: 2 parts by mass; NC-3000: 7 parts by mass; DOPO: 3 parts by mass; SPH-100: 4.1 parts by mass parts by mass; CTBN: 2.2 parts by mass; 4,4'-DDS: 4 parts by mass; 2-ethyl-4 methylimidazole: 0.31 parts by mass; KBM-603: 0.31 parts by mass; solvent (butanone): 60 parts by mass .

[0090] (2) According to the preparation method of Example 1, a flexible copper clad laminate was prepared.

[0091] (3) Carry out performance test to described flexible copper-clad laminate according to the test method of embodiment 1:

[0092] Table 3 Performance measurement results of flexible copper clad laminates

[0093]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com