A kind of high-gloss anti-corrosion coating with rust coating on water-based bottom surface and preparation method thereof

A technology for anti-corrosion coatings and bottom surfaces, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of ignoring the importance of coating storage stability and corrosion resistance, and achieve simple procedures, good adhesion, and good anti-rust performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

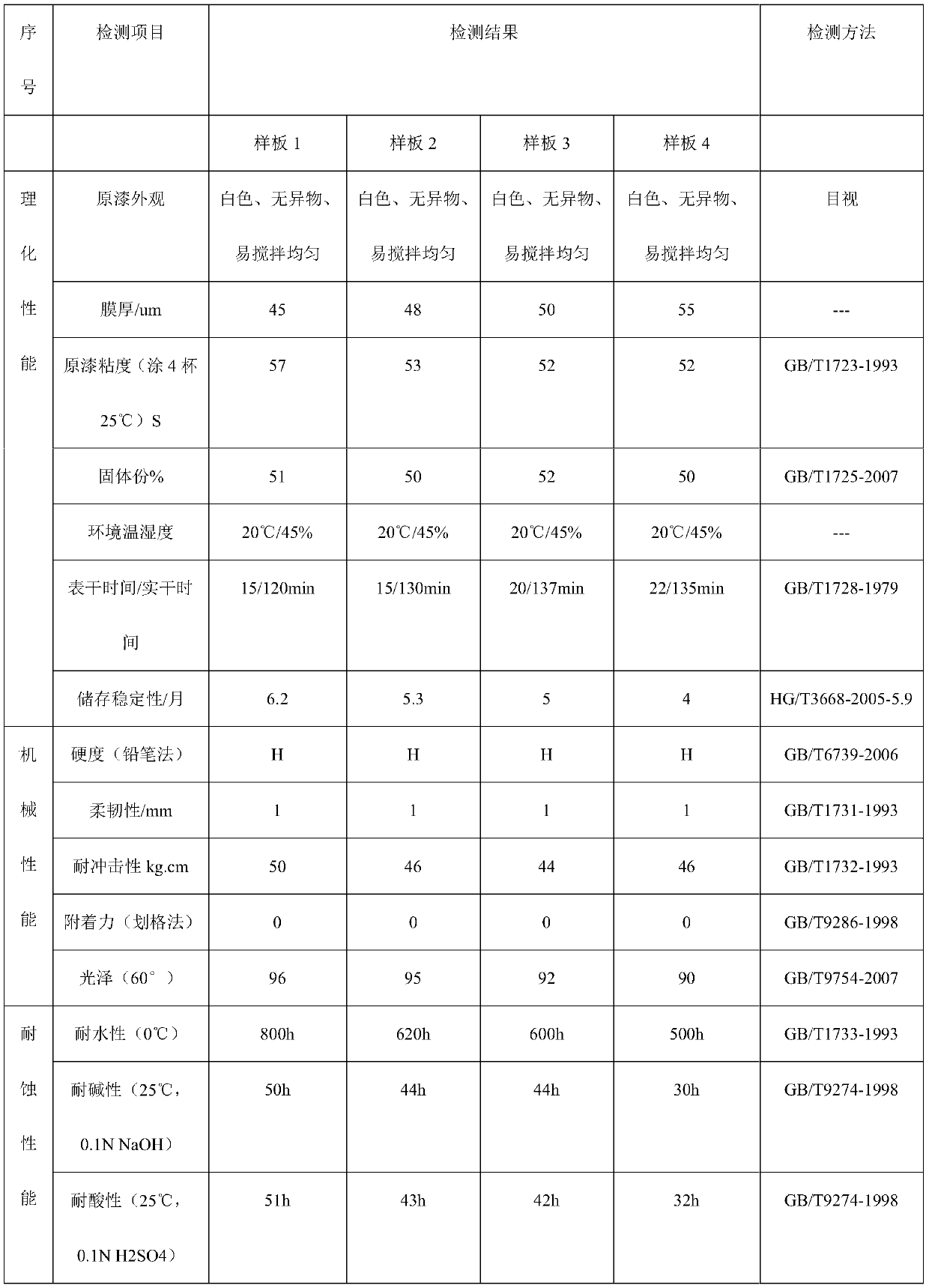

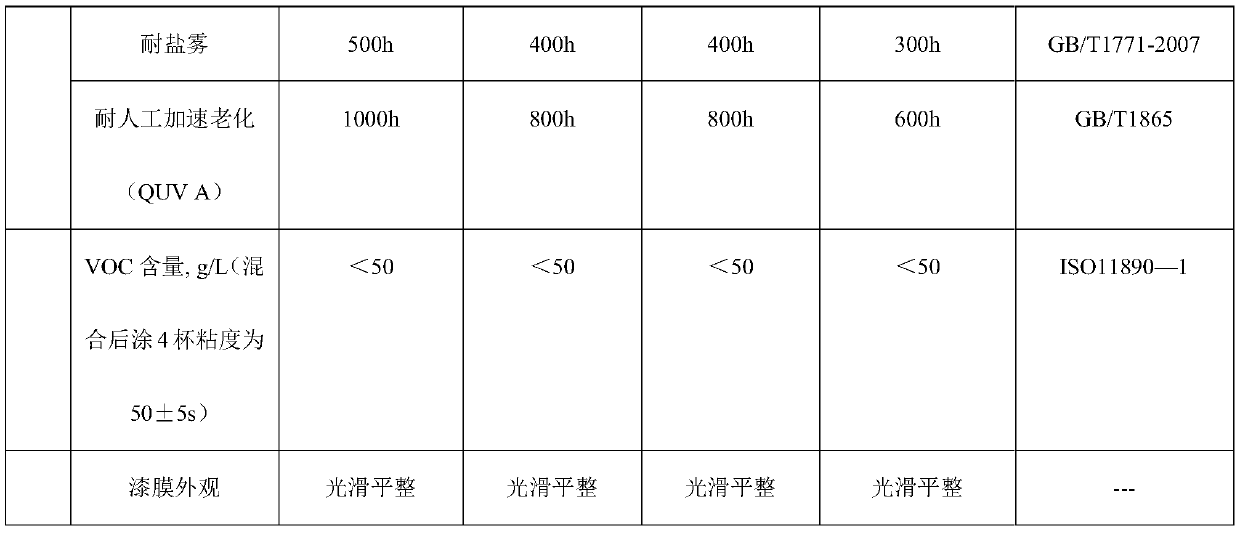

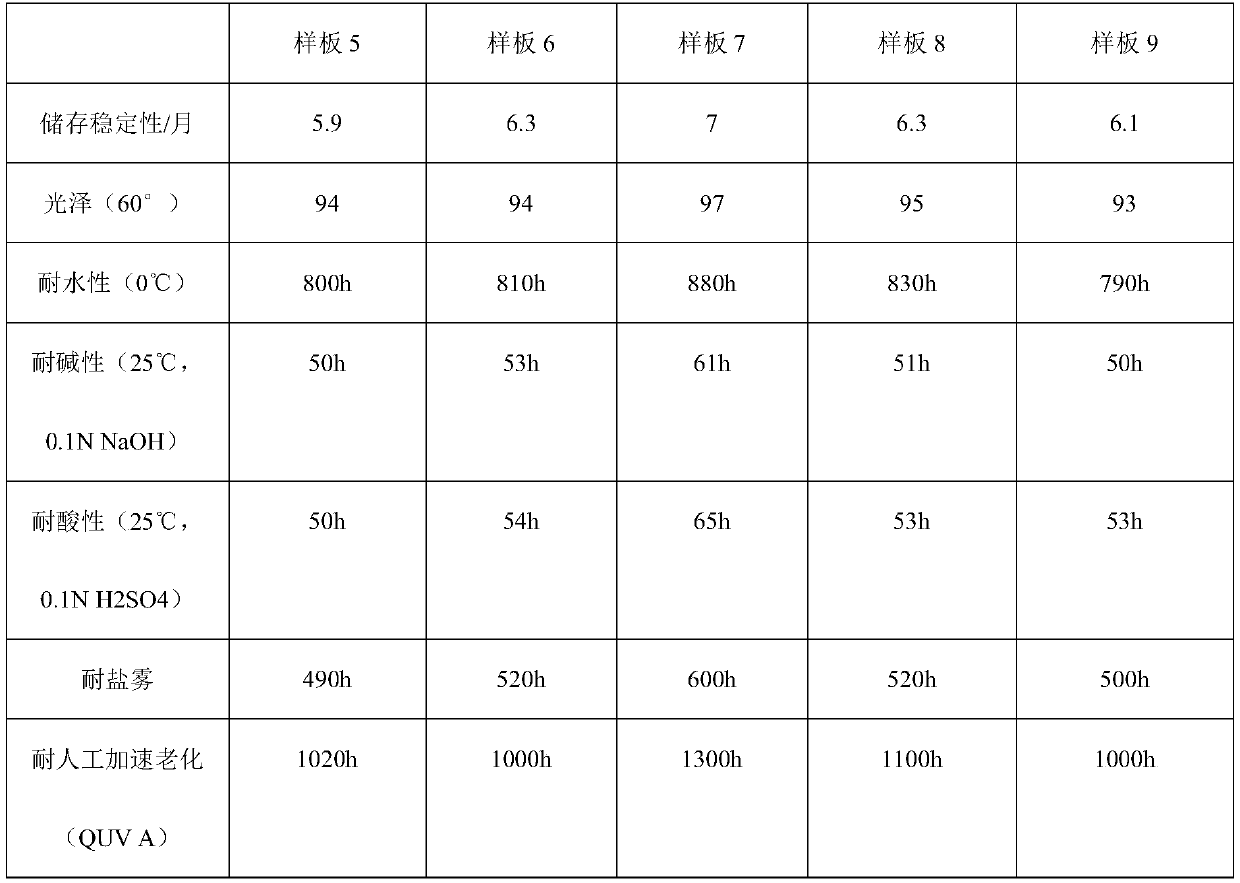

Examples

Embodiment 1

[0056] The preparation of embodiment 1 coating 1

[0057] First, dissolve 0.15 parts of polyoxyethylene ether in deionized water, and use a disperser to dissolve ZrO with a particle size of 10-50nm 2 0.8 parts of nanoparticles are evenly dispersed in it, and set aside; 8 parts of mica powder, 5 parts of titanium dioxide, 1 part of Rebo-60, 1 part of MIT, 1 part of BIT, 0.8 parts of alkyltrimethylammonium chloride, and 1 part of Tego 245 Parts, 1 part of polydimethylsiloxane dispersed in deionized water, disperse for 20 minutes and then grind, when the grinding reaches about 15um, add 60 parts of acrylic emulsion, 28 parts of ethyl fumarate, 8 parts of allyl glycidyl ether 10 parts of polyisocyanate, 4 parts of ammonium persulfate, 7 parts of sodium vinyl sulfonate and ZrO 2 The nanometer solution was stirred rapidly for 3 hours, and the pH was adjusted to 9.0 with diethanolamine. The prepared paint is filtered and packed.

[0058] Comparative Example 1 Coating 2

[0059] F...

Embodiment 2

[0072] Coating 5: 10 parts of ethyl fumarate, 3 parts of allyl glycidyl ether, and the mass parts and preparation methods of the remaining components are the same as those in Example 1 to prepare Coating 5.

Embodiment 3

[0074] Coating 6: 15 parts of ethyl fumarate, 3 parts of allyl glycidyl ether, and the mass parts and preparation methods of the remaining components are the same as those in Example 1 to prepare Coating 6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com