A method for improving the performance and stability of organic solar cells based on thiophene additives

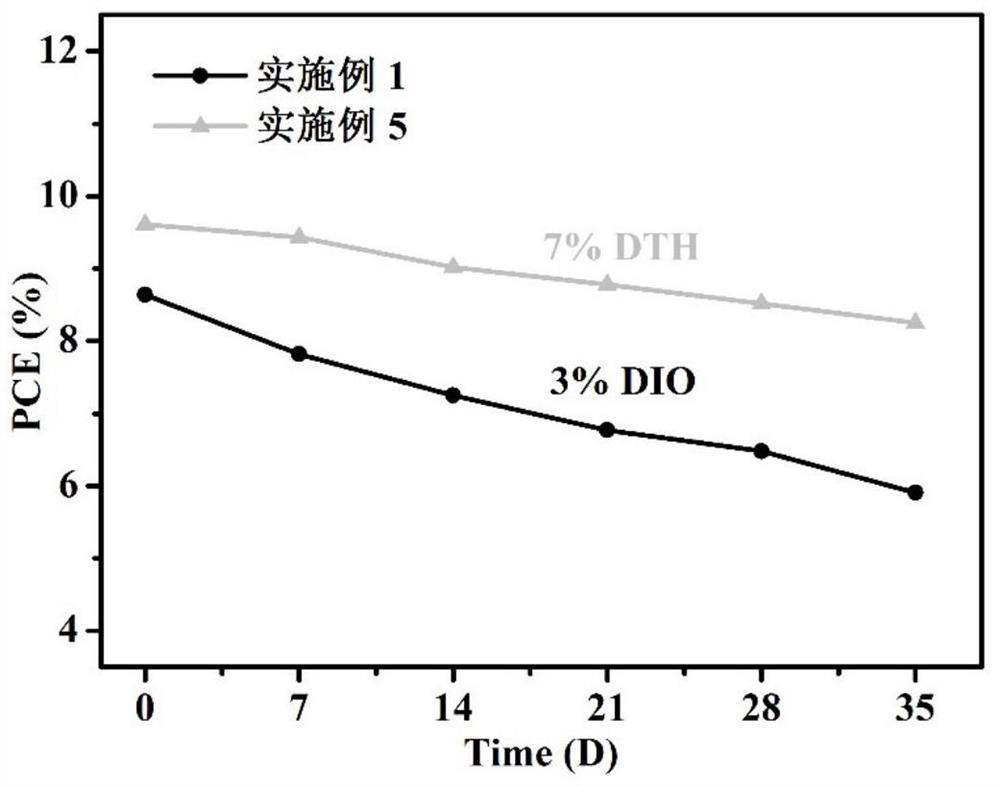

A technology of solar cells and additives, applied in organic chemistry, circuits, photovoltaic power generation, etc., can solve the problems of improving device efficiency and achieve the effects of facilitating mass production, reducing recombination, high heat and light stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

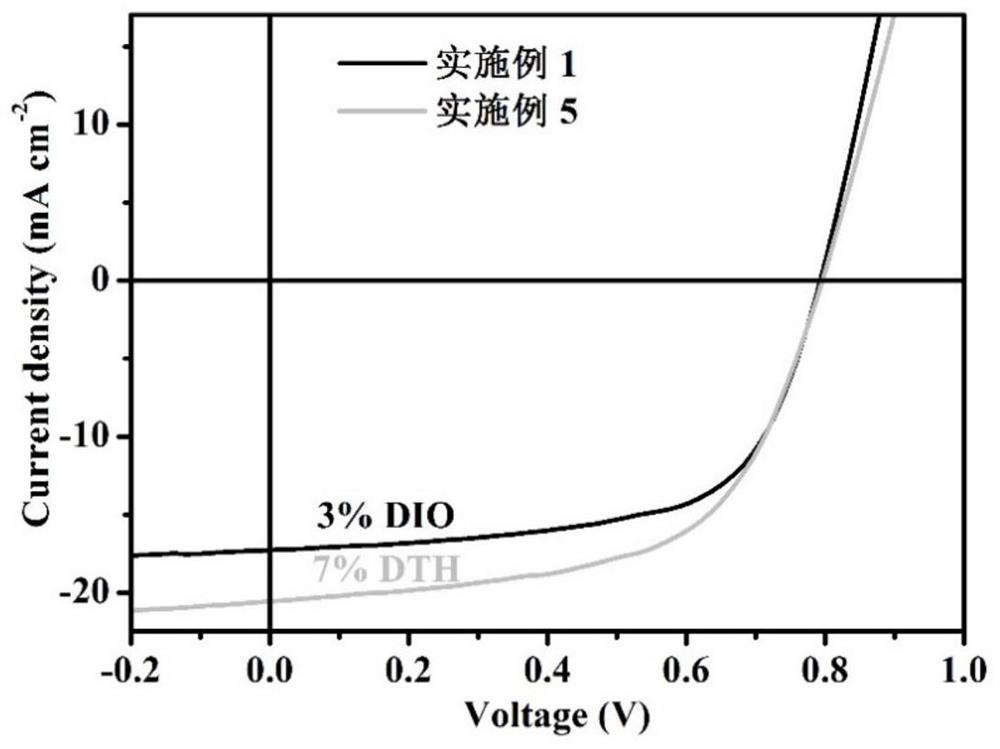

[0028] Embodiment 1 (control group)

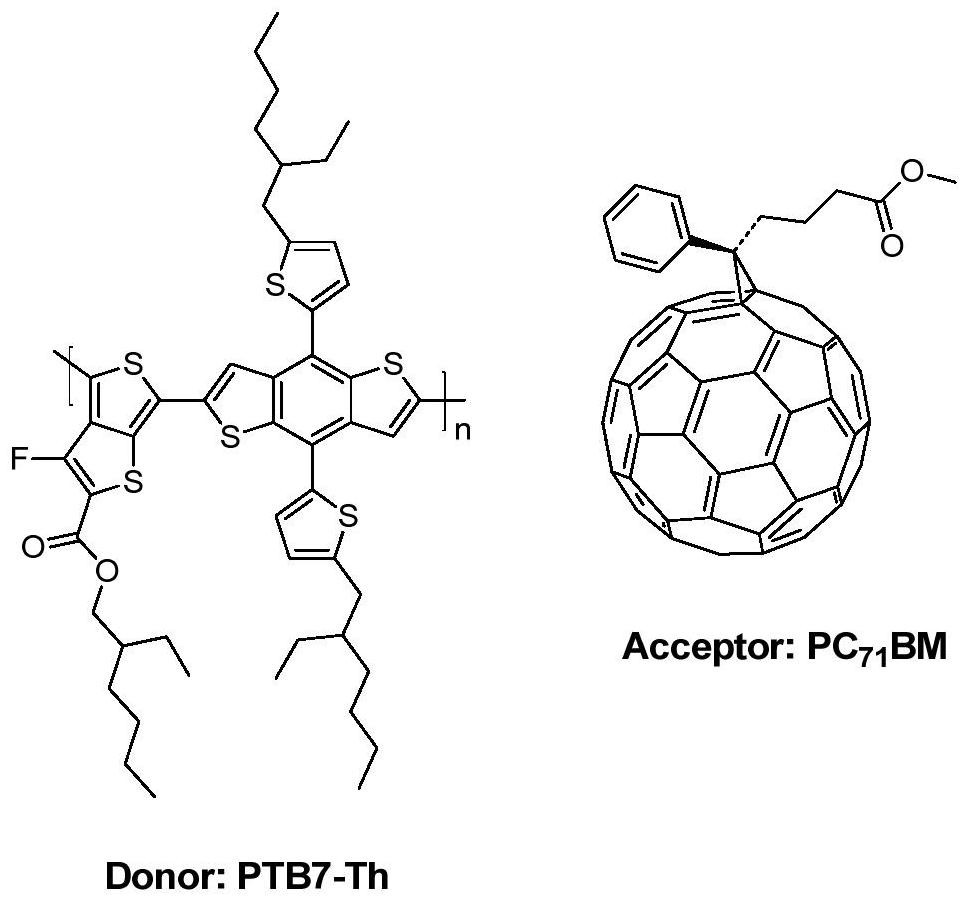

[0029] The first step is to prepare the organic active layer solution: use o-dichlorobenzene as the main solvent to prepare PTB7-Th:PC 71 BM (1:1.5, w / w) at a concentration of 25mg mL -1 (total concentration); add 3% DIO (v / v) to the prepared solution, then place it on a heating and stirring platform, heat and stir at 85° C. for 12 hours, and set aside.

[0030] The second step is to prepare ZnO precursor solution: Weigh 1.05g of zinc acetate dihydrate and 0.28g of ethanolamine and dissolve them in 10mL of 2-methoxyethanol, stir vigorously at room temperature for 12 hours, and set aside.

[0031] The third step is to clean the ITO glass substrate: the etched ITO glass is ultrasonically cleaned with distilled water, acetone and isopropanol for 10 minutes, and then dried with nitrogen, and then placed in a UV-ozone cleaning machine. 15min.

[0032] The fourth step, thin film spin-coating: first spin-coat the ZnO (electron transport layer)...

Embodiment 2

[0037] The first step is to prepare the organic active layer solution: use o-dichlorobenzene as the main solvent to prepare PTB7-Th:PC 71 BM (1:1.5, w / w) at a concentration of 25mg mL -1 (total concentration); add 1% DTH (v / v) to the prepared solution, then place it on a heating and stirring table, heat and stir at 85° C. for 12 hours, and set aside.

[0038]The second step is to clean the ITO glass substrate: the etched ITO glass is ultrasonically cleaned with distilled water, acetone and isopropanol for 10 minutes respectively, and after being blown dry with nitrogen, put it into a UV-ozone cleaning machine for processing 15min.

[0039] The third step, thin film spin coating: first spin coating ZnO (electron transport layer) layer, take the ZnO precursor solution 130 μ L that the second step in the embodiment 1 has prepared, spin coating 40min under the speed of 5000r / min, spin coating After that, it was annealed on a heating plate at 180°C for 30min. Then, move the drie...

Embodiment 3

[0043] The first step is to prepare the organic active layer solution: use o-dichlorobenzene as the main solvent to prepare PTB7-Th:PC 71 BM (1:1.5, w / w) at a concentration of 25mg mL -1 (total concentration); add 3% DTH (v / v) to the prepared solution, then place it on a heating and stirring table, heat and stir at 85° C. for 12 hours, and set aside.

[0044] The second, third and fourth steps are the same as in Example 2.

[0045] With the battery prepared above, in AM 1.5G (intensity is 100mW cm -2 ) irradiation, the photoelectric conversion efficiency of the organic solar cell obtained was 8.36%, slightly lower than the cell efficiency (8.65%) of adding DIO in Example 1, and the specific parameter values are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com