Automotive mildew-proof flame-retardant smoke-suppression PVC (polyvinyl chloride) low-foam crust lining plate and preparation method thereof

A low-foaming, automotive technology, which is applied in the field of mildew-proof, flame-retardant, smoke-suppressing PVC low-foaming crust lining for automobiles and its preparation, can solve the processing and use threats of interior panels, and has no sterilization and mildew-proof effect. Affecting the mechanical properties of interior panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

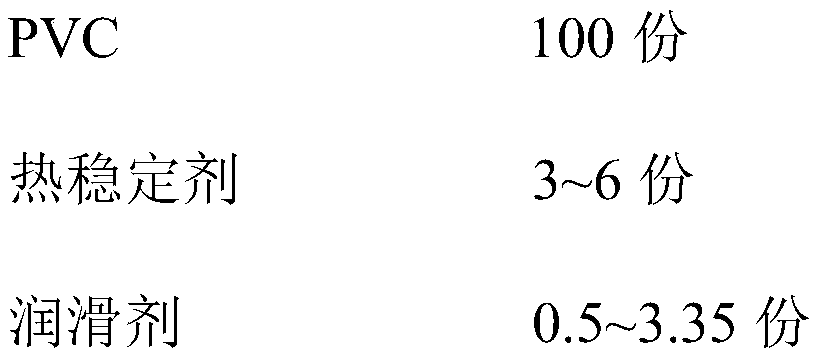

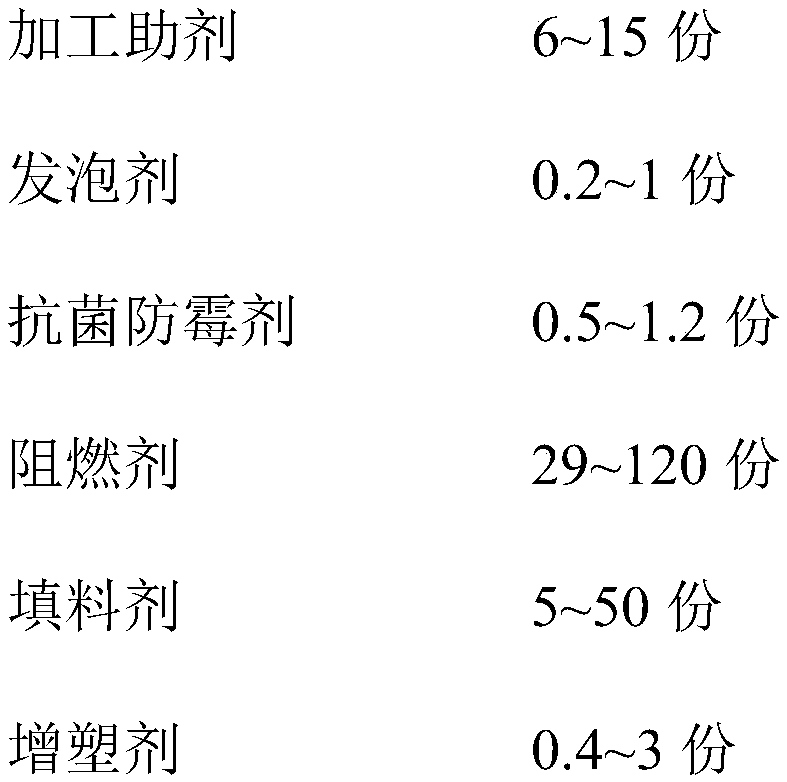

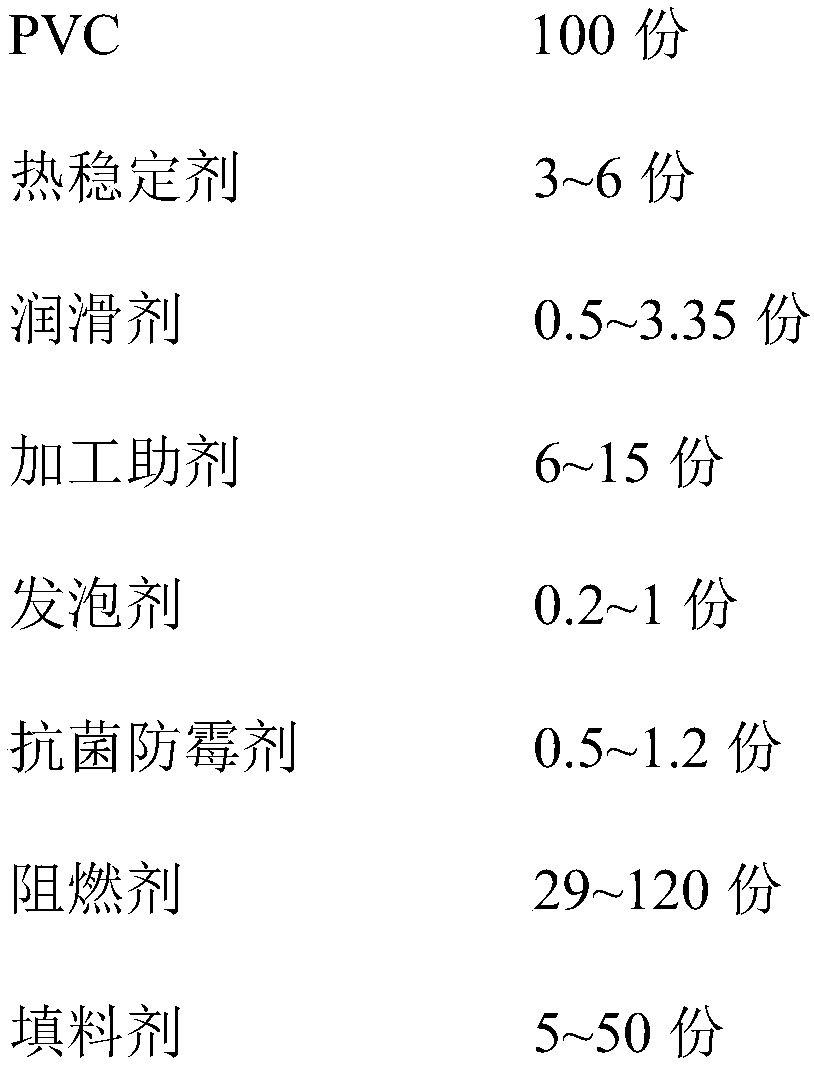

[0034] The present invention also provides a method for preparing a mildew-proof, flame-retardant, smoke-suppressing PVC low-foaming crust lining for automobiles. The preparation method of the mildew-proof, flame-retardant, and smoke-suppressing PVC low-foaming crust lining for automobiles includes the following steps :

[0035] Step 1: Take zinc borate, octamolybdenum in PVC, heat stabilizer, lubricant, processing aid, foaming agent, antibacterial and antifungal agent, filler, plasticizer and flame retardant by weight parts of the raw materials Ammonium acid and antimony-free flame retardant;

[0036] Step 2: Put the raw materials into a high-speed mixing device, stir at a temperature of 90-120°C for 10-20 minutes, and the stirring speed is 1600-2650r / min;

[0037] Step 3: put the high-speed mixed raw materials into the low-speed mixing device, weigh magnesium hydroxide and aluminum hydroxide according to the weight of the raw materials, put them into the low-speed mixing de...

Embodiment 2

[0050] This embodiment provides a mildew-proof, flame-retardant, smoke-suppressing PVC low-foaming crust liner for automobiles, which includes in parts by weight: 100 parts of PVC, 5.6 parts of calcium-zinc stabilizer, 1 part of G60, and 1 part of stearic acid , 1.35 parts of polyethylene wax, 15 parts of methyl methacrylate, 0.2 parts of azodicarbonamide, 0.6 parts of sodium bicarbonate, 1.2 parts of antibacterial and antifungal agents, 8 parts of zinc borate, 30 parts of aluminum hydroxide, 10 parts of hydrogen Magnesium oxide, 5 parts of ammonium octamolybdate, 10 parts of environmentally friendly antimony-free flame retardant, 40 parts of light calcium carbonate and 0.6 parts of oxidized polyethylene wax. The antibacterial and antifungal agent comprises 13% of organic cationic antibacterial functional groups, 4% of antibacterial metal elements and 83% of layered clay.

[0051] Weigh zinc borate, ammonium octamolybdate and environmentally friendly non-toxic compounds in PVC...

Embodiment 3

[0053] This embodiment provides a mildew-proof, flame-retardant, smoke-suppressing PVC low-foaming crust liner for automobiles, which includes in parts by weight: 100 parts of PVC, 5.6 parts of calcium-zinc stabilizer, 1 part of G60, and 1 part of stearic acid , 1.35 parts of polyethylene wax, 15 parts of methyl methacrylate, 0.1 parts of azodicarbonamide, 0.3 parts of sodium bicarbonate, 1.2 parts of antibacterial and antifungal agents, 5 parts of zinc borate, 60 parts of aluminum hydroxide, 20 parts of hydrogen Magnesium oxide, 10 parts of ammonium octamolybdate, 4 parts of environmentally friendly antimony-free flame retardant, 20 parts of light calcium carbonate and 2.5 parts of epoxy soybean oil. The antibacterial and antifungal agent comprises 12% of organic cationic antibacterial functional groups, 3% of antibacterial metal elements and 85% of layered clay.

[0054] Weigh zinc borate, ammonium octamolybdate and environmentally friendly non-toxic compounds in PVC, heat s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| Elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com