Room-temperature silane cross-linked polyolefin and its preparation method

A technology of silane cross-linking and polyolefin, which is applied in the field of silane cross-linking polyolefin and its preparation, low-voltage (10KV) and below wire and cable sheathing materials, which can solve the problems that cannot meet the needs of wire and cable sheathing materials, and achieve a wide range of applications , easy to process, obvious flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

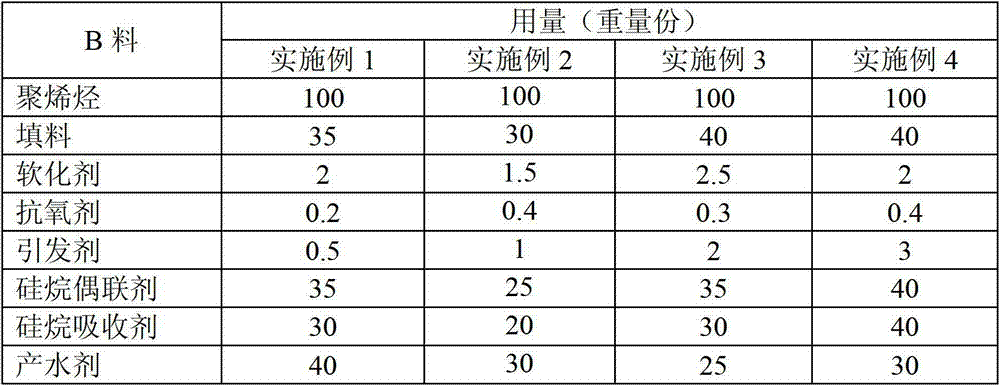

Examples

Embodiment 1

[0044] In embodiment 1, flame retardant filler is magnesium hydroxide, and in embodiment 2, flame retardant filler is magnesium hydroxide and aluminum hydroxide 4: 1 mixture, and in embodiment 3, flame retardant filler is magnesium hydroxide, In Example 4, the flame retardant filler is magnesium hydroxide.

[0045] In Example 1, the filler is a 1:1 mixture of talc powder and clay. In Example 2, the filler is calcium carbonate. In Example 3, the filler is calcined clay. In Example 4, the filler is calcined clay.

[0046] In Example 1, the softener is polyethylene wax 110; in Example 2, the softener is HighFlow; in Example 3, the softener is HighFlow; in Example 4, the softener is HighFlow.

[0047] In Example 1, the antioxidant is 264, in Example 2, the antioxidant is 1010, in Example 3, the antioxidant is 1010, and in Example 4, the antioxidant is 1010.

[0048] In embodiment 1, catalyzer is di-n-octyltin dilaurate, in embodiment 2, catalyzer is dibutyltin dilaurate, in embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com