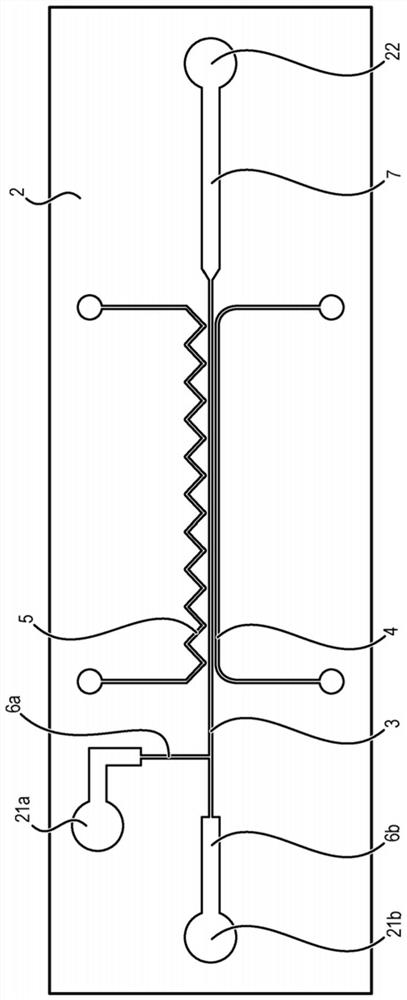

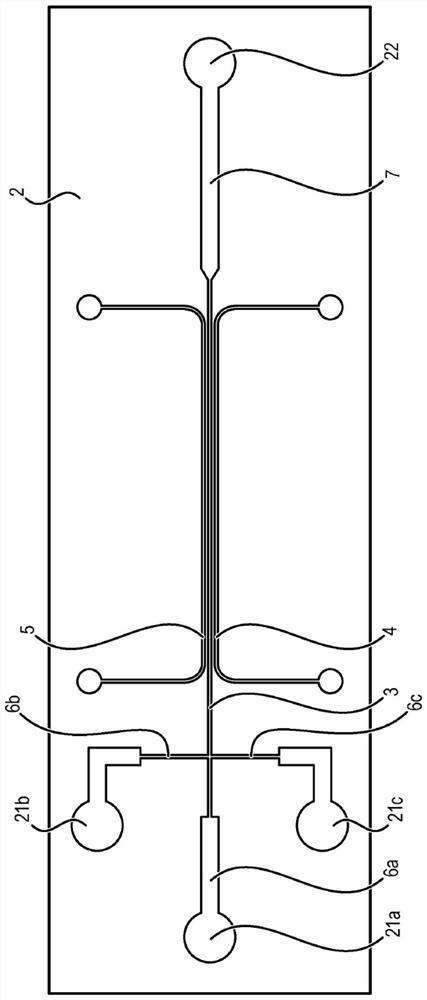

Gas-liquid two-phase plasma reactor

A plasma and liquid technology, applied in chemical/physical/physical-chemical reactors, chemical/physical/physical-chemical fixed reactors, chemical instruments and methods, etc., can solve the problems of large bubble size distribution and incomplete control of double phase flow etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

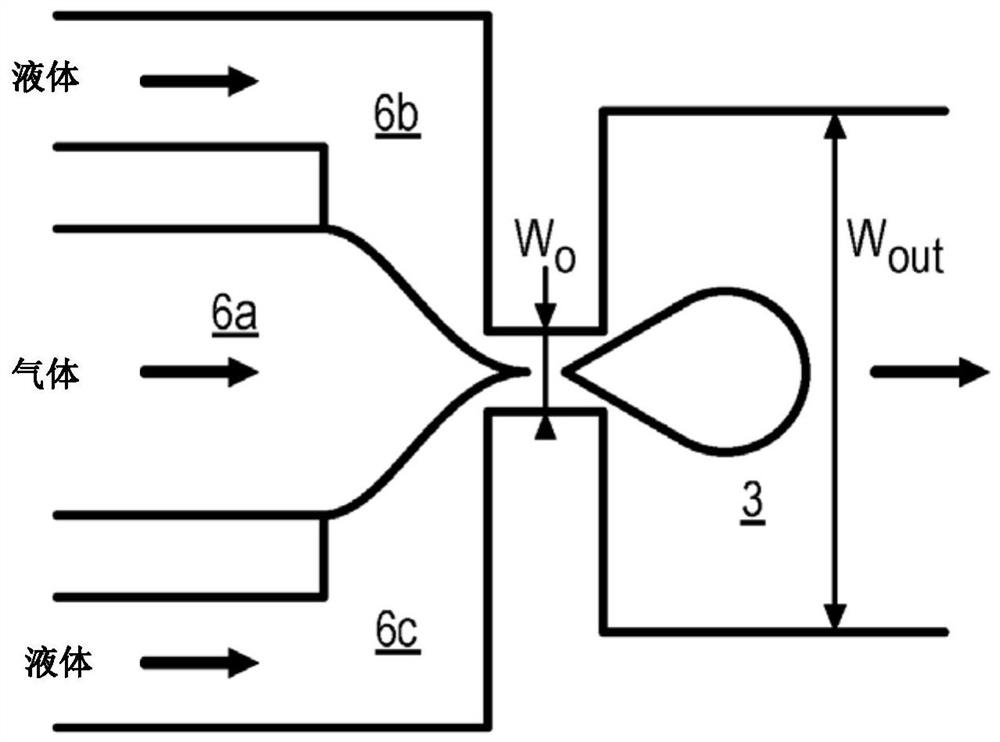

Method used

Image

Examples

Embodiment approach

[0103] According to a first embodiment, the high voltage power supply is a variable high voltage power supply, ie provides a variable high voltage. The high voltage provided by the high voltage power supply will more particularly be a sinusoidal high voltage, the frequency of which is advantageously between 1 Hz and 10 MHz, in particular between 100 Hz and 1 MHz, preferably between 100 Hz and 10 kHz. This creates microdischarges in the gas bubbles at precise frequencies. Advantageously, the frequency will be adapted to the experimental conditions, such as the nature of the gas, the velocity of the gas bubbles, the kinetics of the reaction of interest, etc. In this case, the high voltage (peak-to-peak voltage) is typically between 1 kV and 30 kV, especially between 5 kV and 20 kV, preferably between 10 kV and 15 kV.

[0104] According to a second embodiment, the high-voltage power supply is a high-voltage pulse power supply, ie provides pulsed high voltage. In this case, the ...

example 1

[0156] Materials and methods

[0157] The mercapto-ene based resin NOA-81 (Norland Optical Adhesive) was mainly used to prepare the microfluidic or millimeterfluidic devices according to the present invention. This resin was chosen over the traditionally used PDMS (polydimethylsiloxane) because of its good physical, chemical, electrical and optical properties: i) Unlike PDMS devices, the NOA-81 microreactor is Gases such as air and water vapor are impermeable, which ensures a closed environment for the plasma [1]; ii) the cured NOA-81 has a high elastic modulus (typically 1 GPa), which avoids sagging effect [1]; iii) NOA-81 exhibits less solvent swelling (swelling) effect than PDMS [1]; iv) NOA-81 has a dielectric constant of 4.05 at 1MHz, which also behaves as an insulating material; v) NOA -81 has high transmission in the visible and near UV range, enabling in situ discharge diagnostics (optical emission spectroscopy (OES) or ultrafast camera measurements). Thanks to these...

example 2

[0166] Materials and methods:

[0167] In order to measure the radical species transferred from the plasma bubble to the liquid phase, an EPR (Electron Paramagnetic Resonance) experiment was performed. For these experiments, argon bubbles were immobilized in cavities positioned along the main channel where the liquid flowed. With this geometry, it is easier to control the liquid residence time. Experiments were performed at a liquid flow of 10 μL / min. Under these conditions, the exposure time to the plasma was 0.9 s, corresponding to a ratio S / V of the surface exposed to the plasma phase to the liquid volume of 2000 m 2 / m 3 .

[0168] The liquid phase was deionized water including 0.4 mol / L of 5,5-dimethyl-pyrroline-N-oxide (DMPO), which is a commonly used spin-trap.

[0169] Increase the high voltage gradually until a discharge is observed. In this example, the Pk-Pk voltage is 3kV and its frequency is 2kHz.

[0170] The liquid phase with the spin-trapping agent passe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com