Resolution test card for Nano CT imaging quality detection and preparation method of resolution test card

A technology of imaging quality and resolution, which is applied in the field of resolution test chart and its preparation, can solve problems such as unsatisfactory spatial resolution test chart, difficulty in realizing nanoscale, and not too large depth-to-width ratio. The effect of preparation method control and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The invention provides a method for preparing a resolution test card for Nano CT imaging quality detection, which specifically includes the following steps:

[0020] Step 1. Pretreat the substrate 1 used to prepare the resolution test card, and obtain the pretreated substrate 1;

[0021] The pretreatment is as follows: firstly, the tungsten block is processed into a circular thin tungsten sheet with a diameter of 3-10 mm and a thickness of 200 μm by mechanical processing; then the circular thin tungsten sheet is mechanically polished, and ionized Thinner thins the thickness of the circular thin tungsten sheet after mechanical polishing to 1-5 μm; then uses industrial ethanol to perform ultrasonic cleaning on the thinned circular thin tungsten sheet, and the ultrasonic cleaning time is 5-10 minutes; Finally, the cleaned circular thin tungsten sheet is placed in a drying dish for drying to obtain the pretreated substrate 1;

[0022] Step 2. Place the pretreated substrate...

Embodiment 1

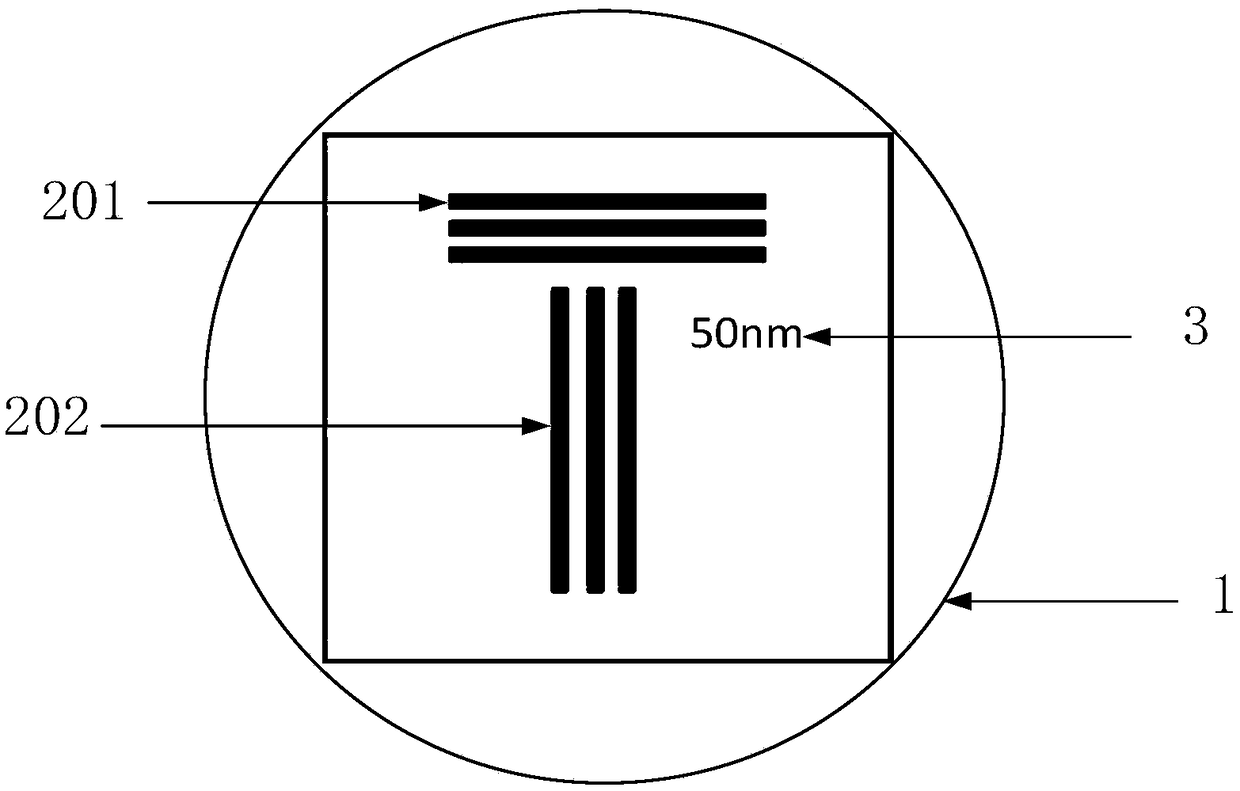

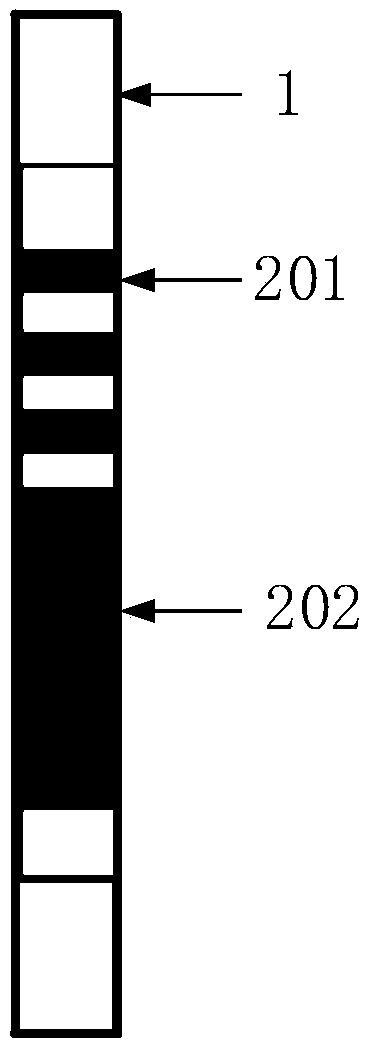

[0031] Such as figure 1 and figure 2 As shown, a resolution test card for Nano-CT imaging quality provided by the present invention includes a substrate 1 , horizontal stripes 201 , vertical stripes 202 and a scale 3 . The base 1 is preferably a circular thin tungsten sheet with a diameter of 3 mm and a thickness of 1 μm. The horizontal stripes 201 and the vertical stripes 202 are both rectangular parallelepiped, each has 3 stripes, each horizontal stripe 201 and each vertical stripe 202 have an etching width of 50 nm, an etching length of 3 μm, and an etching depth of 1 μm The overall horizontal stripes 201 and the vertical stripes 202 are distributed in a T shape on the substrate, and the horizontal stripes 201 and the vertical stripes 202 are etched by gallium ion beams emitted by a gallium ion source in a helium ion microscope. The helium The working condition of the gallium ion beam of the ion microscope is that the accelerating voltage is 25kV, the beam current is 10p...

Embodiment 2

[0040] Another resolution test card for Nano-CT imaging quality provided by the present invention includes a substrate 1 , horizontal stripes 201 , vertical stripes 202 and a scale 3 . The base 1 is preferably a circular thin tungsten sheet with a diameter of 10 mm and a thickness of 5 μm. The horizontal stripes 201 and the vertical stripes 202 are both cuboids, each having 5 stripes, each of the horizontal stripes 201 and the vertical stripes 202 has an etching width of 1 μm, an etching length of 5 μm, and an etching depth of 5 μm. The stripes 201 and the vertical stripes 202 are distributed in a T shape, and the horizontal stripes 201 and the vertical stripes 202 are etched by the gallium ion beam emitted by the gallium ion source in the helium ion microscope. The working conditions of the gallium ion beam of the helium ion microscope are The acceleration voltage is 30kV, the beam current is 15pA, and the duty ratio of the acceleration voltage is 1:1. The scale 3 uses the ga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com