A kind of preparation method adopting vacuum consumable electric arc melting cufe alloy material

A vacuum consumable arc and alloy material technology, applied in the field of non-ferrous metal alloys, can solve the problems of easy substitution of impurity elements and high cost, and achieve the effects of less macrosegregation, high quality, and stable composition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A preparation method adopting vacuum consumable arc melting CuFe alloy material, comprising the following steps:

[0026] (1) Mixing of raw materials: The raw material of Cu is selected from electrolytic copper powder, the copper content of electrolytic copper powder is up to 99.8%, the particle size is -120 mesh, the bulk ratio is 0.6g / cm3, the raw material of Fe is selected from atomized iron powder, the particle size of atomized iron powder is -150 mesh, and the apparent density is 2.2Mg / m3. The composition and weight percentage of the material are: Cu70%, Fe30%. The raw materials are sprayed into the mixer, which is filled with a protective gas composed of helium and argon, and mixed in the mixer, the stirring speed is 1000r / min, the temperature is 150°C, and the mixing time is 2h;

[0027] (2) Compression: Put the mixed powder into the rubber sleeve, firstly perform mechanical vibration for 30s, then roll the material for 3 minutes, and then reverse the material fo...

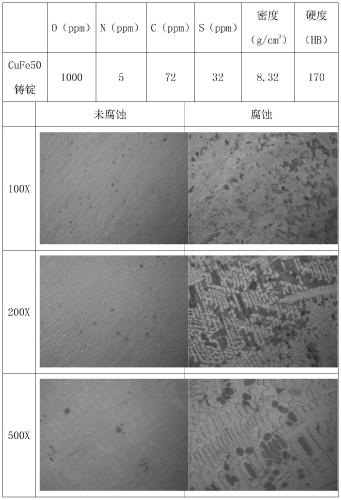

Embodiment 2

[0031] A preparation method adopting vacuum consumable arc melting CuFe alloy material, comprising the following steps:

[0032](1) Mixing of raw materials: The raw material of Cu is selected from electrolytic copper powder, the copper content of electrolytic copper powder is up to 99.8%, the particle size is -120 mesh, the bulk ratio is 0.8g / cm3, the raw material of Fe is selected from atomized iron Powder, the particle size of atomized iron powder is -150 mesh, the apparent density is 2.5Mg / m3, the composition and weight percentage of the material are: Cu50%, Fe50%, the required raw materials are weighed according to the proportion, and pulsed The raw materials are sprayed into the mixer, which is filled with protective gas composed of helium and argon, and mixed in the mixer, the stirring speed is 1200r / min, the temperature is 180°C, and the mixing time is 3h;

[0033] (2) Compression: Put the mixed powder into the rubber sleeve and perform mechanical vibration for 40 secon...

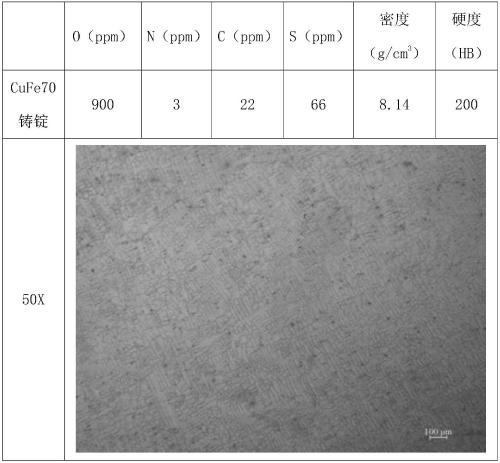

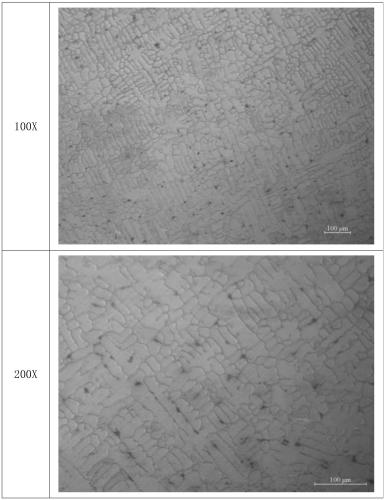

Embodiment 3

[0037] A preparation method adopting vacuum consumable arc melting CuFe alloy material, comprising the following steps:

[0038] (1) Mixing of raw materials: The raw material of Cu is selected from electrolytic copper powder, the copper content of electrolytic copper powder is 99.8%, the particle size is -120 mesh, the bulk ratio is 1.07g / cm3, the raw material of Fe is selected from atomized iron Powder, the particle size of atomized iron powder is -150 mesh, the apparent density is 2.9Mg / m3, the material composition and its weight percentage are: Cu30%, Fe70%, take the required raw materials according to the proportion, and pulse The raw materials are sprayed into the mixer, which is filled with protective gas composed of helium and argon, and mixed in the mixer, the stirring speed is 1400r / min, the temperature is 200°C, and the mixing time is 4h;

[0039] (2) Compression: put the mixed powder into the rubber sleeve, firstly perform mechanical vibration for 60s, then roll the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com