Preparation method of oil fume high-efficiency purification additive

An additive and high-efficiency technology, applied in chemical instruments and methods, separation methods, detergent compositions, etc., can solve the problems of low purification efficiency of sub-micron particles and difficult oil pollution treatment, and achieve low corrosion and good water solubility , high purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

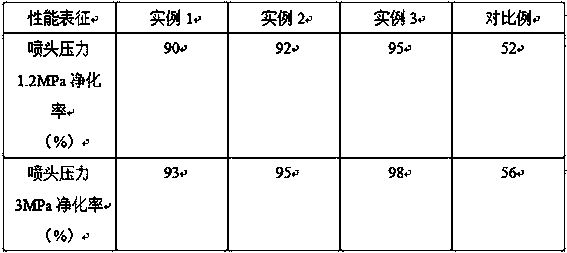

Examples

example 1

[0031] Take 200g of citrus peel and mix it with 300g of deionized water to obtain a mixture. Heat the mixture to boiling and cook it; collect the reflux liquid with a condenser tube; take 100g of the reflux liquid, 1g of ammonium chloride and 20g of dichloromethane and mix them for 10 minutes , to obtain two phases of oil and water, discharge the water phase to obtain cleaning agent A; get 20g triethanolamine, 10g oleic acid and 100g deionized water and mix to obtain cleaning agent B; take 100g fresh spinach and put it into 500g boiling deionized water , filter after 10min, take 200g of filtrate, 20g of ethylene glycol monobutyl ether, 60g of isopropanol and 40g of ethylene glycol ether and mix them as solvent; take 6g of sodium polyphosphate, 2g of sodium dodecylbenzenesulfonate, 4g of emulsifier Mix OP-10 and 100g of deionized water to obtain additives; mix 20g of cleaning agent A, 10g of cleaning agent B, 100g of solvent and 10g of additives to obtain a mixed solution, and s...

example 2

[0033] Take 300g of citrus peel and mix it with 450g of deionized water to obtain a mixture, heat the mixture to boiling and cook; collect the reflux liquid with a condenser tube; take 150g of the reflux liquid, 1.5g of ammonium chloride and 30g of dichloromethane and mix, let stand After 10 minutes, the two phases of oil and water were obtained, and the water phase was discharged to obtain cleaning agent A; 30g of triethanolamine, 15g of oleic acid and 150g of deionized water were mixed to obtain cleaning agent B; 150g of fresh spinach was taken and placed in 750g of boiling deionized In water, filter after 10 minutes, take 300g of filtrate, 30g of ethylene glycol monobutyl ether, 90g of isopropanol and 60g of ethylene glycol ether as a solvent; take 9g of sodium polyphosphate, 3g of sodium dodecylbenzenesulfonate, 6g of emulsified Mix agent OP-10 and 150g deionized water to obtain additives; take 30g cleaning agent A, 15g cleaning agent B, 150g solvent and 15g additives and m...

example 3

[0035]Take 400g of citrus peel and mince it and mix it with 600g of deionized water to obtain a mixture, heat the mixture to boiling and cook; collect the reflux liquid with a condenser tube; take 200g of the reflux liquid, 2g of ammonium chloride and 40g of dichloromethane and mix them, let stand for 10min , to obtain two phases of oil and water, discharge the water phase to obtain cleaning agent A; get 40g triethanolamine, 20g oleic acid and 200g deionized water and mix to obtain cleaning agent B; take 200g fresh spinach and put it into 1000g boiling deionized water , filter after 10min, take 400g filtrate, 40g ethylene glycol monobutyl ether, 120g isopropanol and 80g ethylene glycol ethyl ether and mix as solvent; take 12g sodium polyphosphate, 4g sodium dodecylbenzene sulfonate, 8g emulsifier Mix OP-10 and 200g of deionized water to obtain additives; mix 40g of cleaning agent A, 20g of cleaning agent B, 200g of solvent and 20g of additives to obtain a mixed solution, and st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com