Porcine circovirus bivalent genetic engineering vaccine

A porcine circovirus, amino acid technology, applied in the field of biotechnology genetic engineering, to achieve good safety, high immunogenicity, and the effect of preventing infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1 The source of the fusion protein gene

[0021] The present invention comprehensively analyzes the gene sequence, antigen structure and epidemiological research progress of the main epidemic strains of porcine circovirus type 1 and type 3 at home and abroad, according to the amino acid sequence of its structural protein Cap protein, uses relevant bioinformatics software to analyze its relative Water, antigenicity, plasticity, surface accessibility and secondary structure are analyzed to predict possible B-cell epitopes and T-cell epitopes, and relevant reports are combined to determine PCV-1 and PCV-3 Cap proteins subunit. The vaccine skeleton structure is formed by flexible Linker connection and then connected in series with IL-5. The overall structure of the vaccine is:

[0022] PCV1 Cap - PCV3 Cap - IL-5 - Tag

Embodiment 2

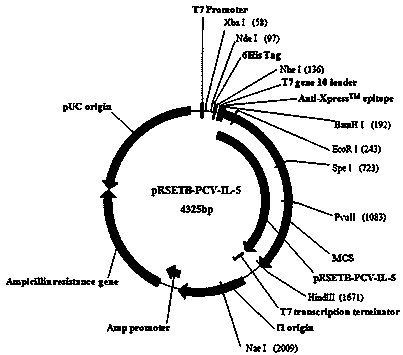

[0023] Example 2 Construction of Escherichia coli expression vector and expression strain

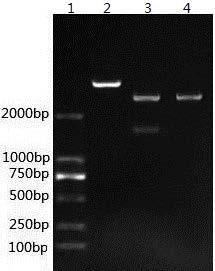

[0024] The designed polypeptide encoding nucleotides in Example 1 were sent to Shanghai Handsome Biotechnology Co., Ltd. for synthesis. BamHI (5' end) and HindIII (3' end) restriction enzyme sites were designed at both ends of the nucleotide fragment respectively. The synthesized fragment was cloned into the pMD18T vector, and sequence determination confirmed that the inserted gene fragment was consistent with the involved sequence (see the sequence list). The recombinant plasmid was named pMD18T-PCV-IL-5, and the plasmid was digested with the corresponding restriction endonuclease. The Escherichia coli expression vector was pRSETB plasmid from Invitrogen Company, and the same restriction endonuclease was also used. Digestion conditions: 10 μL reaction system, 2 μL plasmid, 5 activity units of restriction endonuclease (New England biolabs), 1 μL 10× buffer, complete with deionized water...

Embodiment 3

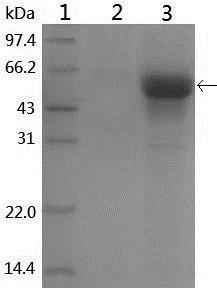

[0028] Example 3 Fermentation, purification and emulsification of engineering bacteria

[0029]Fermentation Inoculate the production strains into 2 mL of LB liquid medium containing 100 μL / mL ampicillin, and culture at 37°C for 12 hours with shaking at 180 rpm to activate the strains. Put the activated strains into shake flasks at an inoculum size of 1:100, shake and culture at 37°C until OD600=3, and then inoculate them into fermenters at a ratio of 10%. The medium used for fermentation is a semi-synthetic medium prepared with distilled water and does not contain any antibiotics. Calibrate the dissolved oxygen and pH electrodes, turn on the tank to stir at 300 rpm, and sterilize the tank on-line. When the temperature of the culture solution in the tank drops to 37°C, calibrate the pH and dissolved oxygen (OD) zero point. The fermentation temperature is 37.0°C±0.1°C, the dissolved oxygen is controlled at about 20%, and the pH is controlled at 7.0. After inoculation, when the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com