PTA (Pure Terephthalic Acid) energy-saving and consumption-reducing device and homogeneous pre-mixing method before CTA (Crude Terephthalic Acid) oxidation reaction

An oxidation reactor and pre-mixing technology, applied in chemical instruments and methods, chemical industry, organic chemistry, etc., can solve the problems of short mixing time, prone to side reactions, poor homogeneous mixing effect, etc., to improve the oxidation reaction rate , Increase the main reaction yield, reduce the effect of pressure and temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

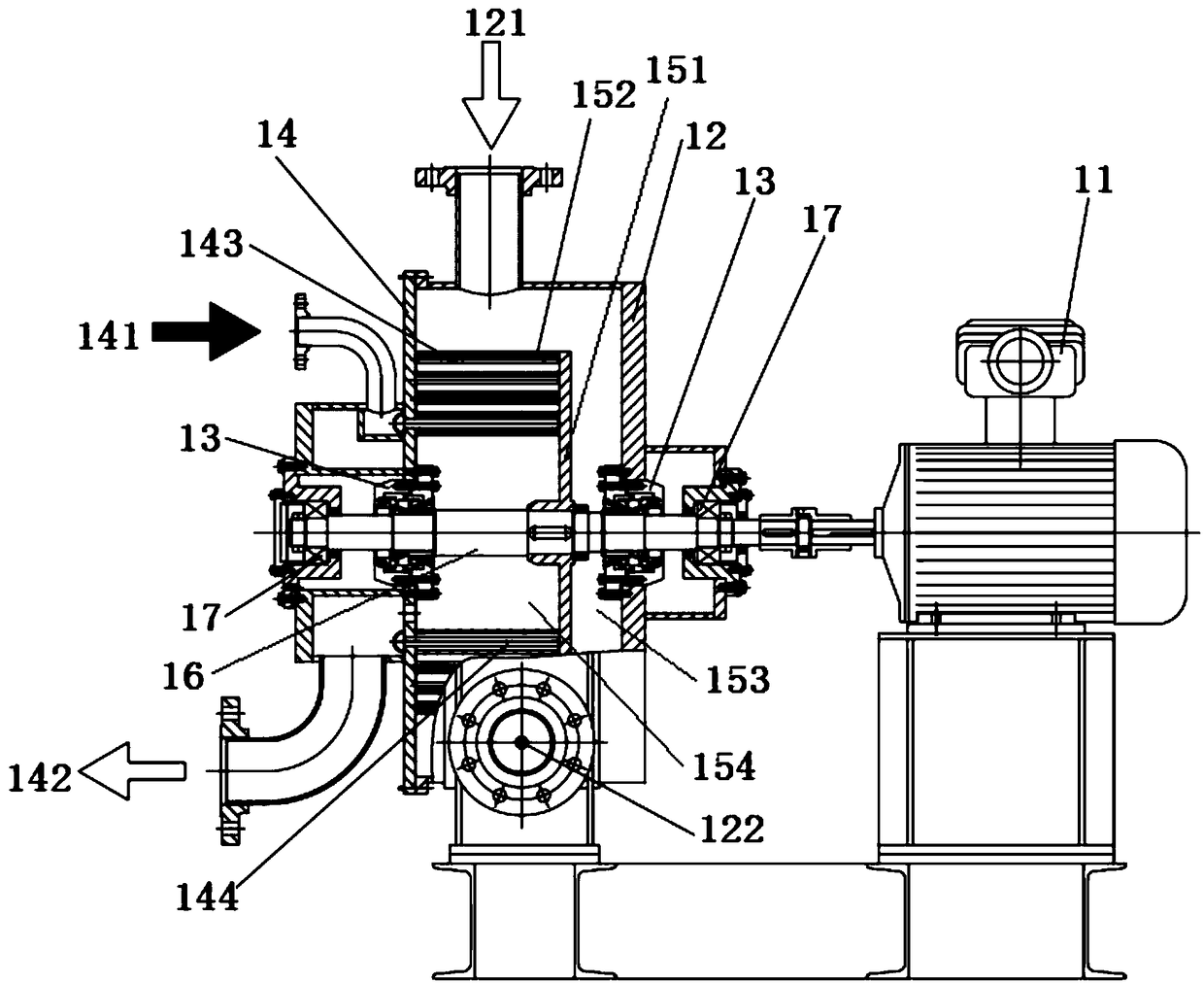

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

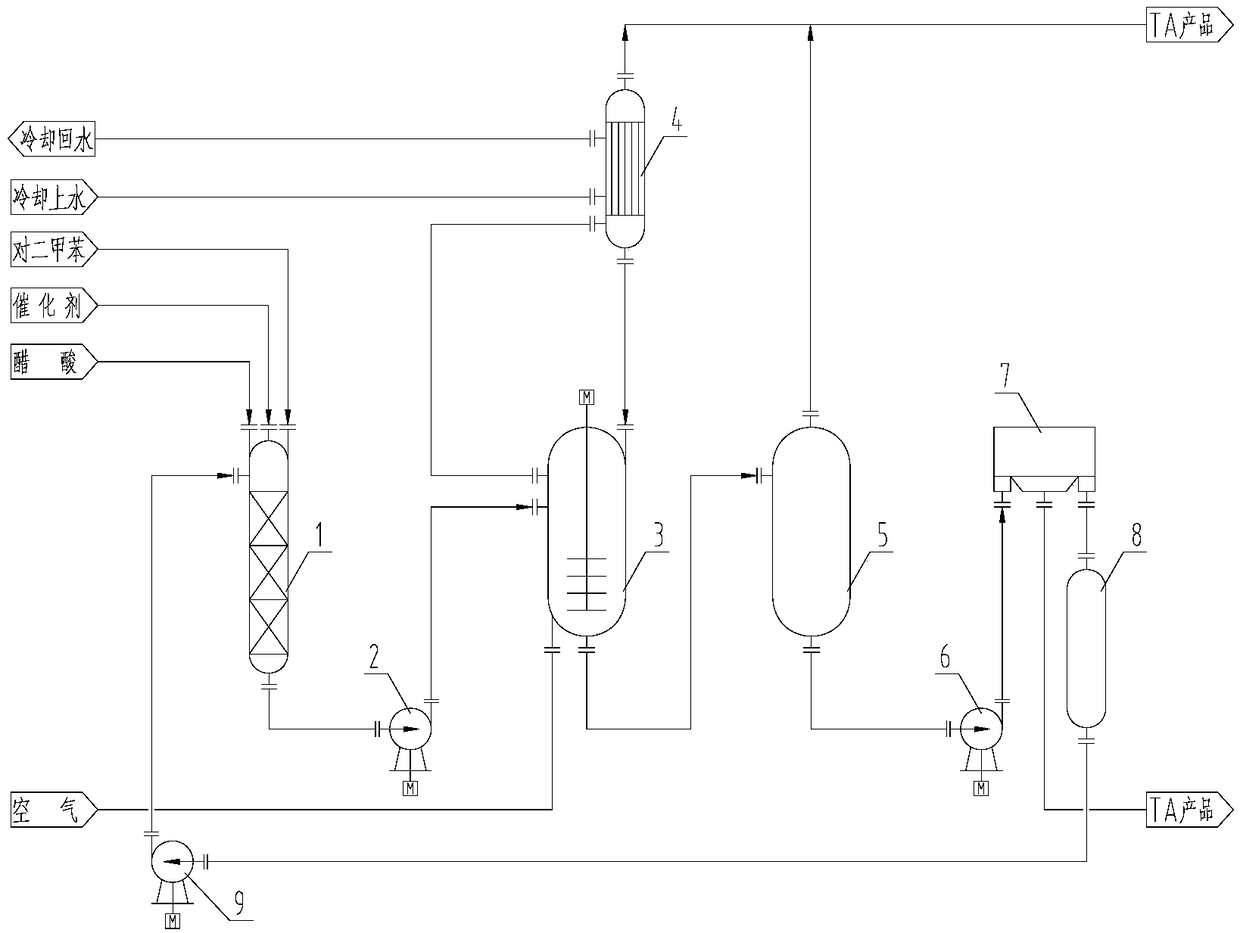

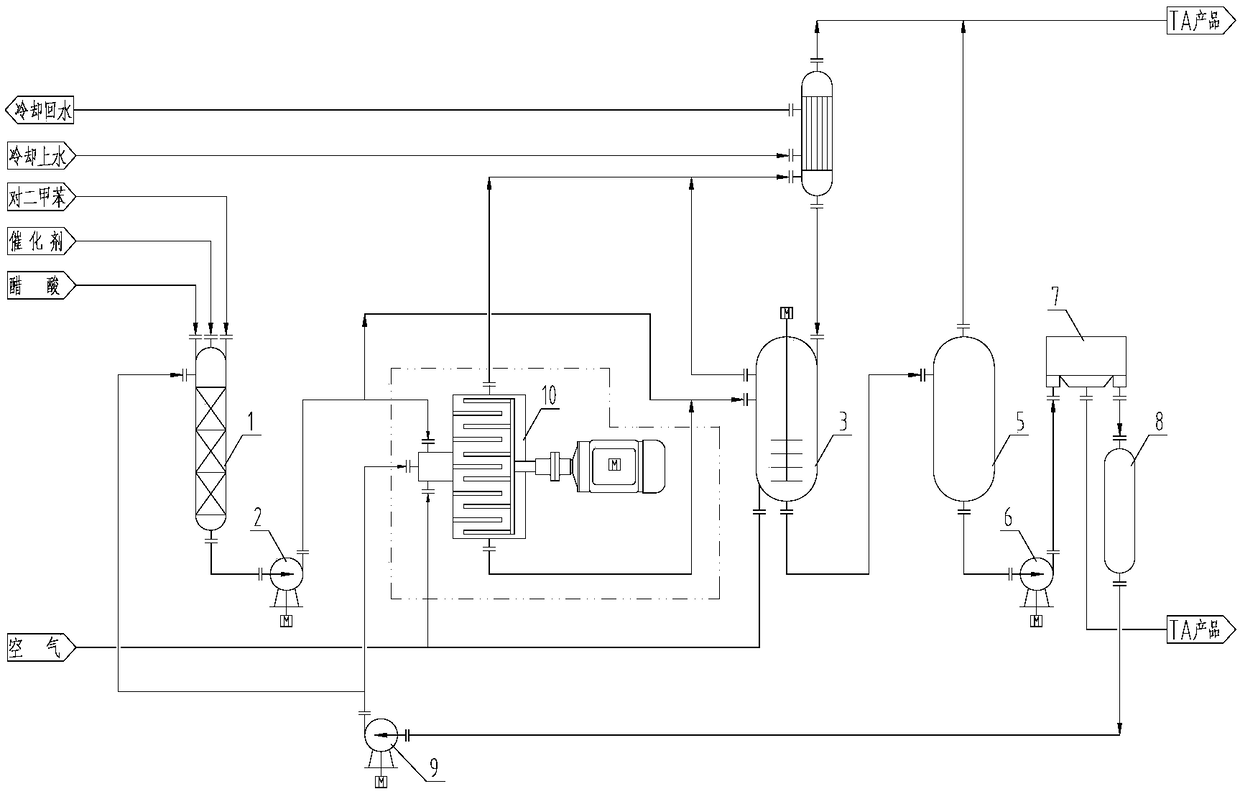

[0041] Such as figure 2 As shown, a PTA energy-saving and consumption-reducing device includes a feed mixing device 1, a supergravity homogeneous premixing reactor 10, an oxidation reactor 3, a condenser 4, a crystallization tank 5, a filter 7 and a mother liquor tank 8.

[0042] The feed mixing device is preferably a mixing tank or a static mixer, etc., which are used to pre-mix the raw materials p-xylene, solvent acetic acid and catalyst. Among them, the catalyst is preferably one or a combination of cobalt acetate, manganese acetate or accelerator tetrabromoethane.

[0043] The supergravity homogeneous premixed reactor is arranged between the feed mixing device and the oxidation reactor.

[0044] The layout of the oxidation reactor 3, the condenser 4, the crystallization tank 5, the filter 7 and the mother liquor tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com