A kind of liquid phase oxidation method of cyclohexane

A cyclohexane and said technology are applied in chemical instruments and methods, hydrocarbon oxidation to prepare oxygen-containing compounds, organic chemistry, etc., and can solve the problems of large cyclohexane circulation, high energy consumption, cyclohexanone and cyclohexanol Low yield and other problems, to achieve the effect of improving reaction rate and heat transfer rate, strong heat transfer efficiency, and safety assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

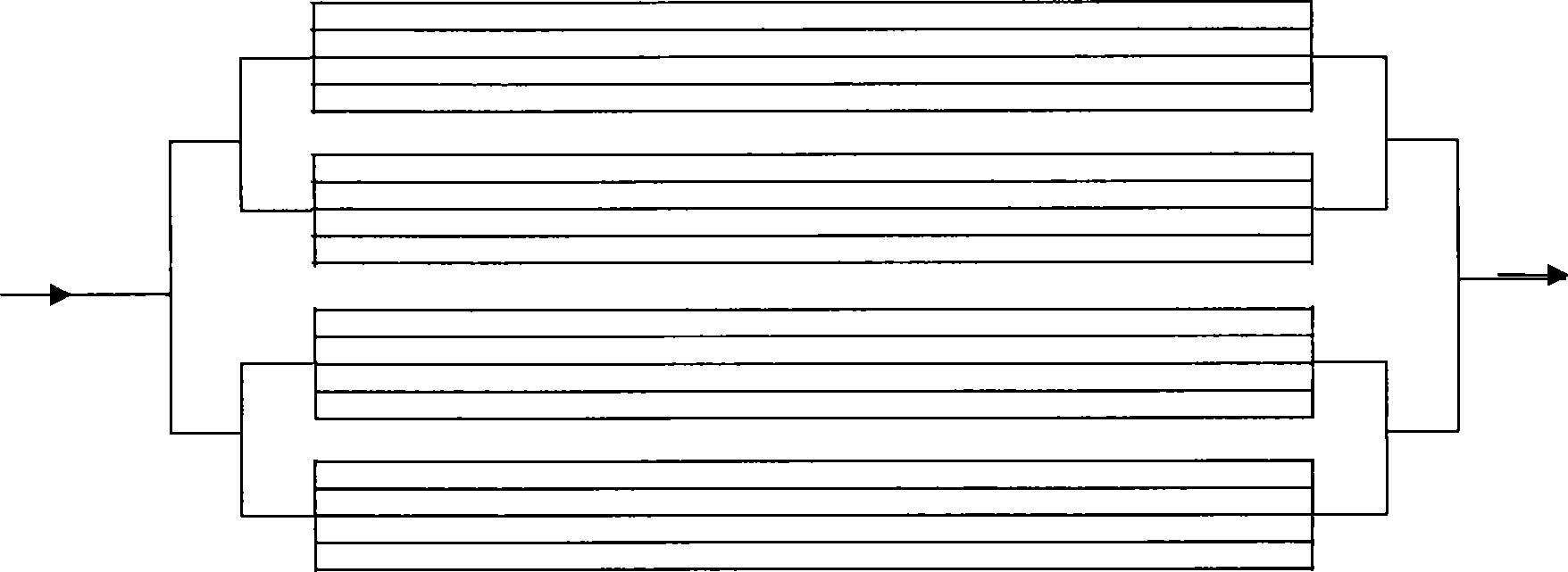

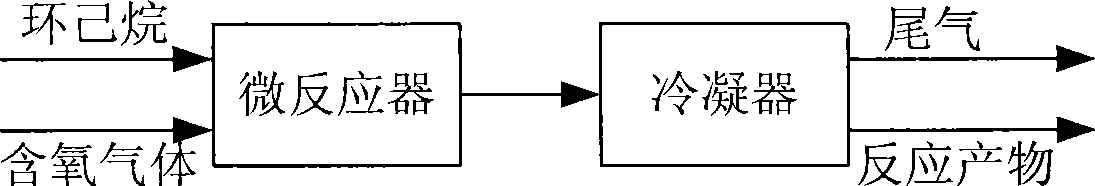

[0060] It adopts the form of micro-channel reactor, see the structure of liquid inlet and micro-channel figure 1 , The size of the reaction microchannel is the same as the inlet size.

[0061] Reaction process see image 3 . The microchannel reactor disc is 5cm wide, 6cm long, and 2mm thick; the channels are divided into four groups, each group has five channels, the channel length is 50mm, and the spacing is 0.5mm; the spacing of each group is 2mm, and there is a 2mm lower part of each sub-channel entrance 1 micropore of 200μm×200μm; correspondingly designed on the back of the reaction disk corresponding to short channels, gas-liquid T-type mixing, square channel with gas inlet channel size of 300μm×300μm, gas inlet and liquid inlet are perpendicular; liquid inlet size is 300μm×300μm square channel.

[0062] The cyclohexane oxidation reaction is carried out with pure oxygen as the oxidant. The initiator in the cyclohexane solution is a mixture of cyclohexanone and cyclohexanol wi...

Embodiment 2

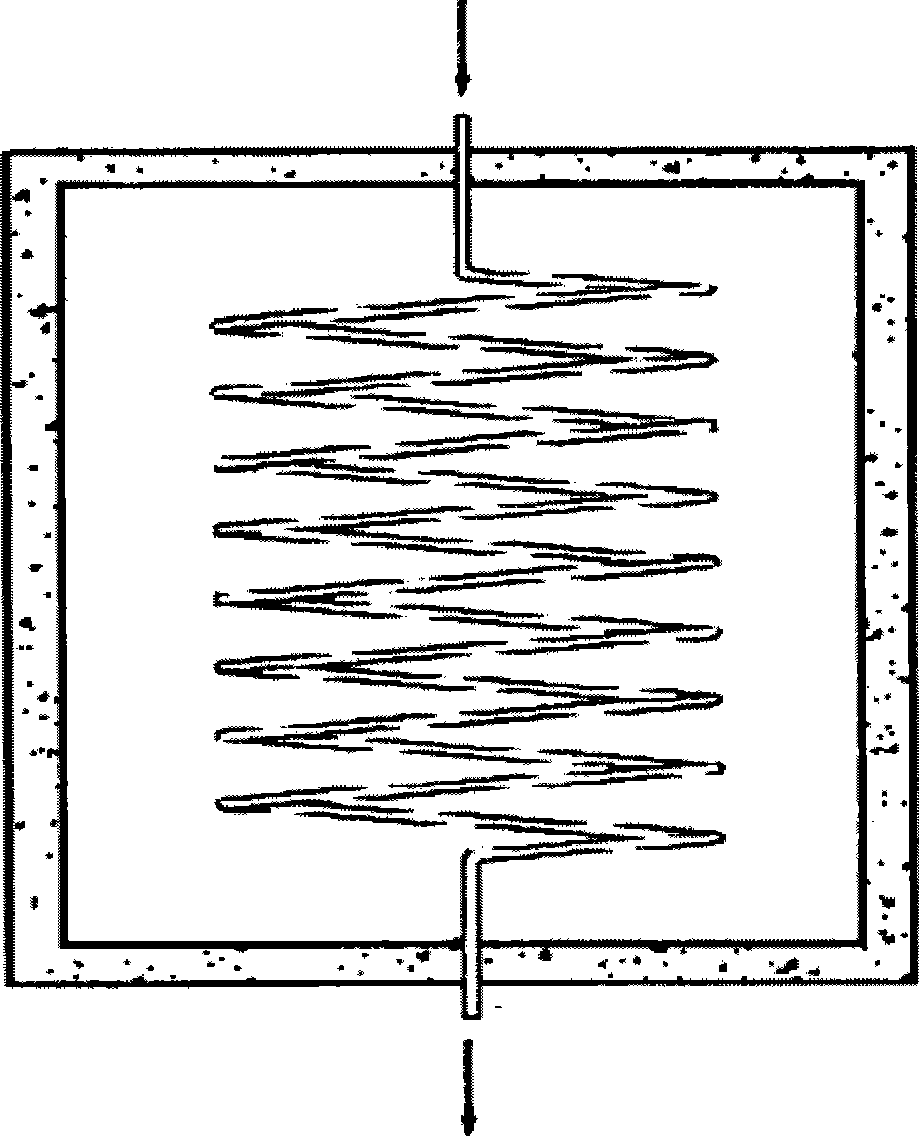

[0064] Reaction process see image 3 . The reactor is a micro-coiled tube reactor with an inner diameter of 0.53mm and a length of 50m. Air is used as the oxidant for the cyclohexane oxidation reaction. The initiator in the cyclohexane solution is a mixture of cyclohexanone and cyclohexanol with a mass ratio of 1:1, accounting for 0.5% of the weight of cyclohexane. The reaction temperature is 170°C and the pressure 1.3MPa, residence time 5min, gas / liquid molar ratio 1.0:1. The conversion rate of cyclohexane is 2.5%, and the total selectivity of cyclohexanone, cyclohexanol, and cyclohexyl hydroperoxide is 98%.

Embodiment 3

[0066] Reaction process see image 3 . The reactor is a micro-coiled tube reactor with an inner diameter of 1.3mm and a length of 12m. Air is used as the oxidant to carry out the cyclohexane oxidation reaction. The initiator in the cyclohexane solution is a mixture of cyclohexanone and cyclohexanol with a mass ratio of 1:1, accounting for 0.8% of the weight of cyclohexane. The reaction temperature is 165°C and the pressure 1.25MPa, residence time 5min, gas / liquid molar ratio 1.1:1. The conversion rate of cyclohexane is 3.5%, and the total selectivity of cyclohexanone, cyclohexanol, and cyclohexyl hydroperoxide is 86%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com