Catalytic oxidation process device and catalytic oxidation process method for magnesium sulfite

An oxidation device and catalytic oxidation technology, applied in the direction of magnesium sulfate, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of non-continuous production, low oxidation rate, large device volume, etc., and achieve a small number of devices and high operating efficiency High, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

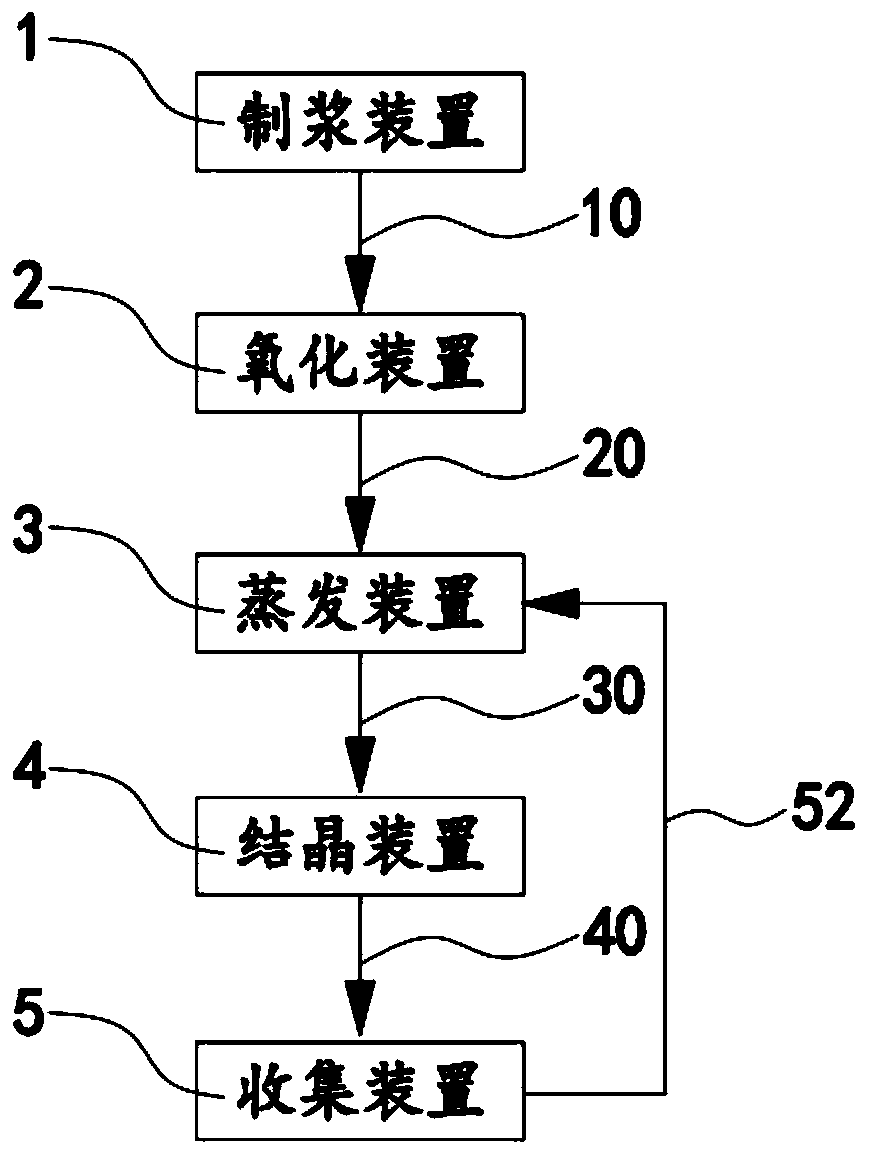

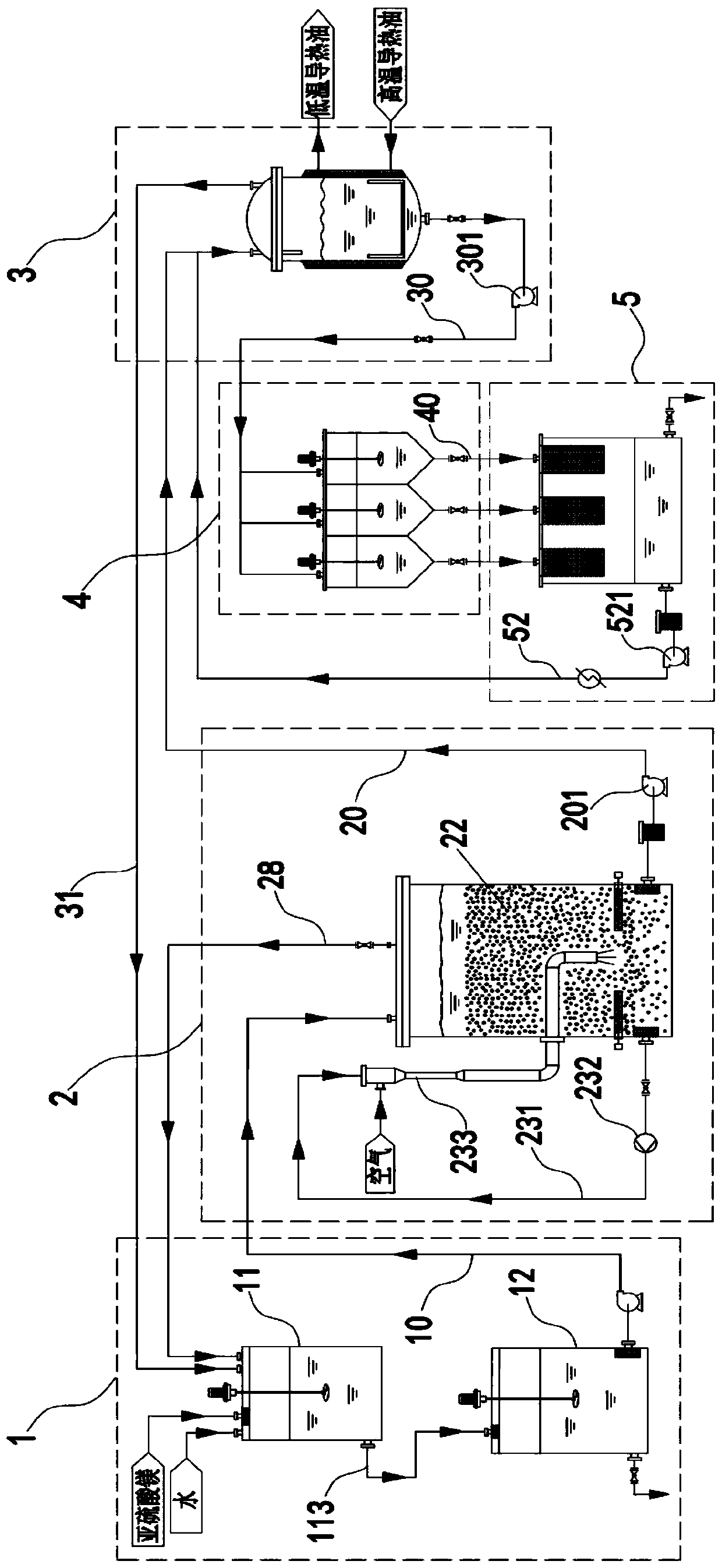

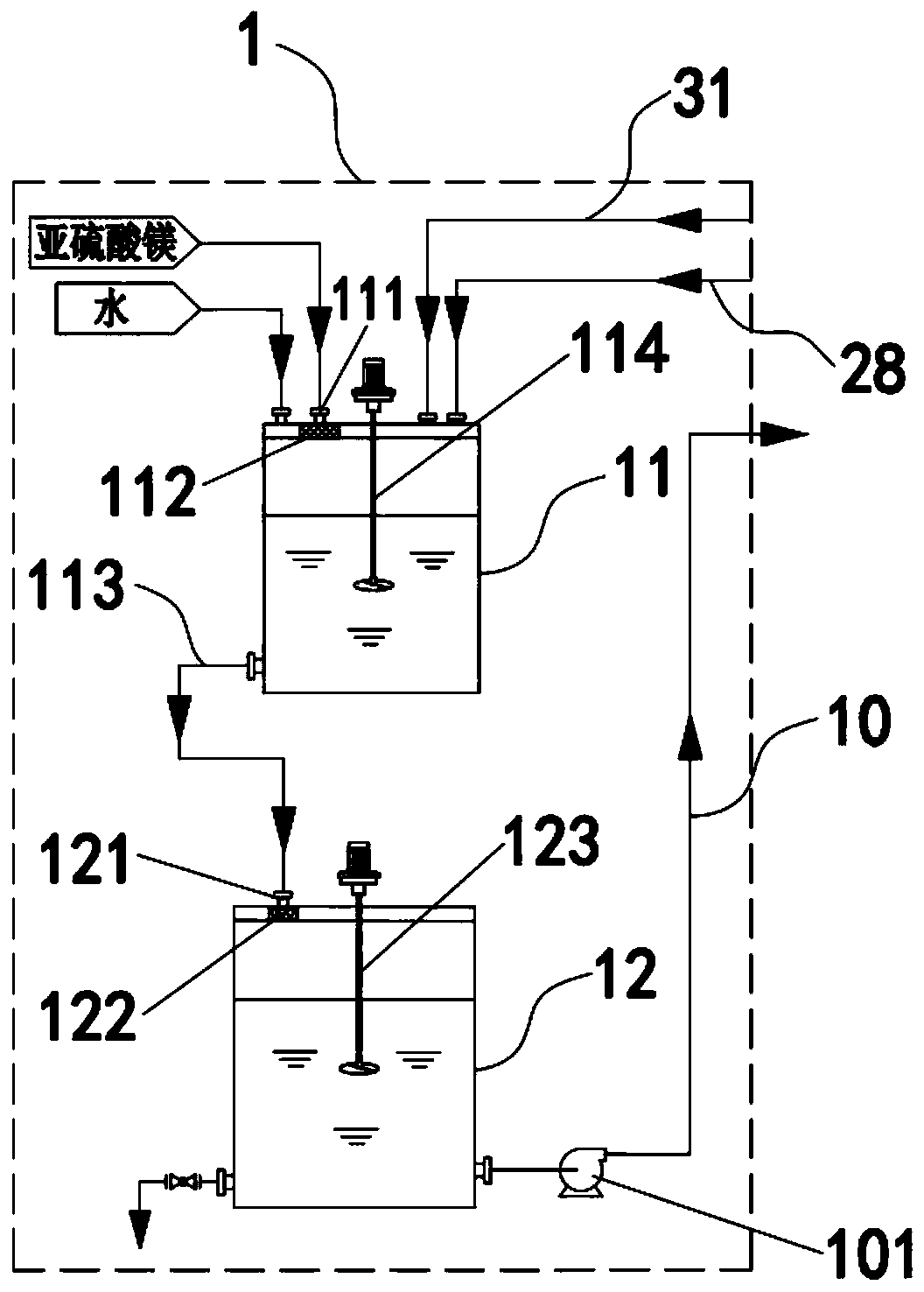

[0066] Such as Figure 1-6 Shown, a kind of catalytic oxidation process unit for magnesium sulfite, this process unit comprises successively connected by pipeline:

[0067] Pulping device 1, for adding water to magnesium sulfite raw material to make magnesium sulfite slurry;

[0068] Oxidation device 2 is located at the downstream of pulping device 1, and a slurry delivery pipe 10 communicating with each other is provided between the oxidation device 2 and pulping device 1. A slurry delivery pump 101 is arranged on the slurry delivery pipe 10, and a Gas delivery pipe 21, gas delivery pipe 21 is used for passing into oxidation reaction required air in oxidation device 2, magnesium sulfite slurry is sent into oxidation device 2 through slurry delivery pipe 10 and carries out oxidation reaction, generates magnesium sulfate solution;

[0069] The evaporating device 3 is located at the downstream of the oxidizing device 2. A solution delivery pipe 20 communicating with each other ...

Embodiment 2

[0092] Such as Figure 1-2 with Figure 7 Shown, adopt catalytic oxidation process device of the present invention to carry out catalytic oxidation to solid magnesium sulfite, its processing method is specifically as follows:

[0093] S1. Slurry preparation: Add solid magnesium sulfite raw material and water into the slurry preparation tank 11 to prepare a magnesium sulfite slurry with a concentration of 35%;

[0094] S2. Catalytic oxidation: Send the magnesium sulfite slurry prepared in S1 to the oxidation device 2 through the slurry delivery pipe 10, the delivery flow rate is 300kg / h, and air is introduced, and the catalytic oxidation is carried out at a temperature of 60°C and normal pressure Reaction generates magnesium sulfate solution;

[0095] In step S2, the volume ratio of the amount of catalyst added to the reaction solution in the oxidation device 2 is 80 g:1 L, and the molar ratio of magnesium sulfite to air is 1:2.5.

[0096] S3. Evaporation and concentration: ...

Embodiment 3

[0101] Such as Figure 1-2 with Figure 7 Shown, adopt catalytic oxidation process device of the present invention to carry out catalytic oxidation to solid magnesium sulfite, its processing method is specifically as follows:

[0102] S1. Slurry preparation: Add solid magnesium sulfite raw material and water into the slurry preparation tank 11 to prepare magnesium sulfite slurry with a concentration of 40%;

[0103] S2. Catalytic oxidation: send the magnesium sulfite slurry prepared in S1 to the oxidation device 2 through the slurry delivery pipe 10, the delivery flow rate is 300kg / h, and air is introduced, and the catalytic oxidation is carried out at a temperature of 55°C and normal pressure Reaction generates magnesium sulfate solution;

[0104] In step S2, the volume ratio of the amount of catalyst added to the reaction solution in the oxidation device 2 is 100 g:1 L, and the molar ratio of magnesium sulfite to air is 1:3.

[0105] S3. Evaporation and concentration: the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com