Biogas fermentation system

A biogas fermentation and fermentation tank technology, applied in the field of biogas fermentation system, can solve the problems of unstable air pressure, incomplete discharge, poor sealing performance, etc., and achieve the effects of avoiding vibration and noise, improving emulsification effect and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

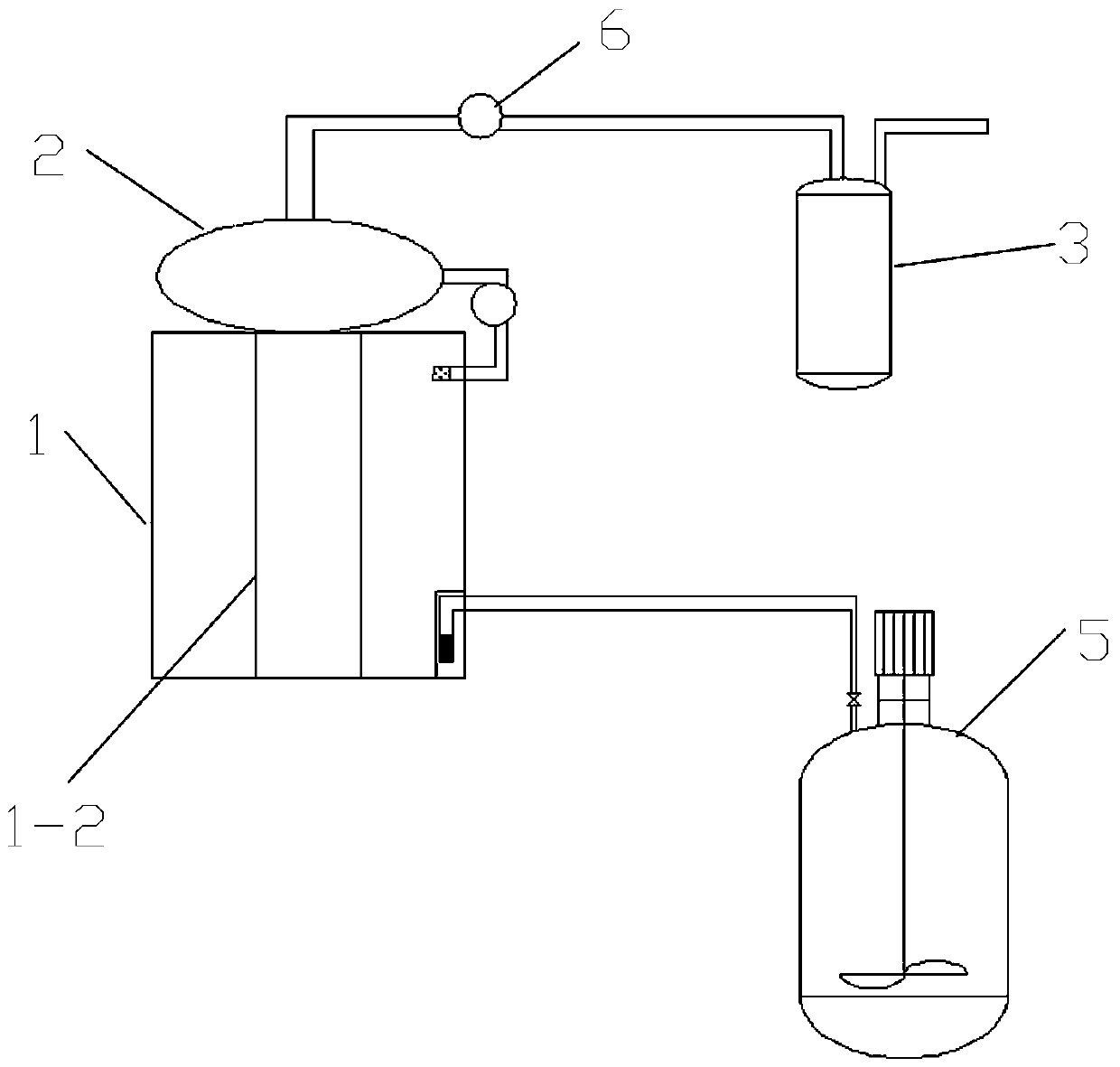

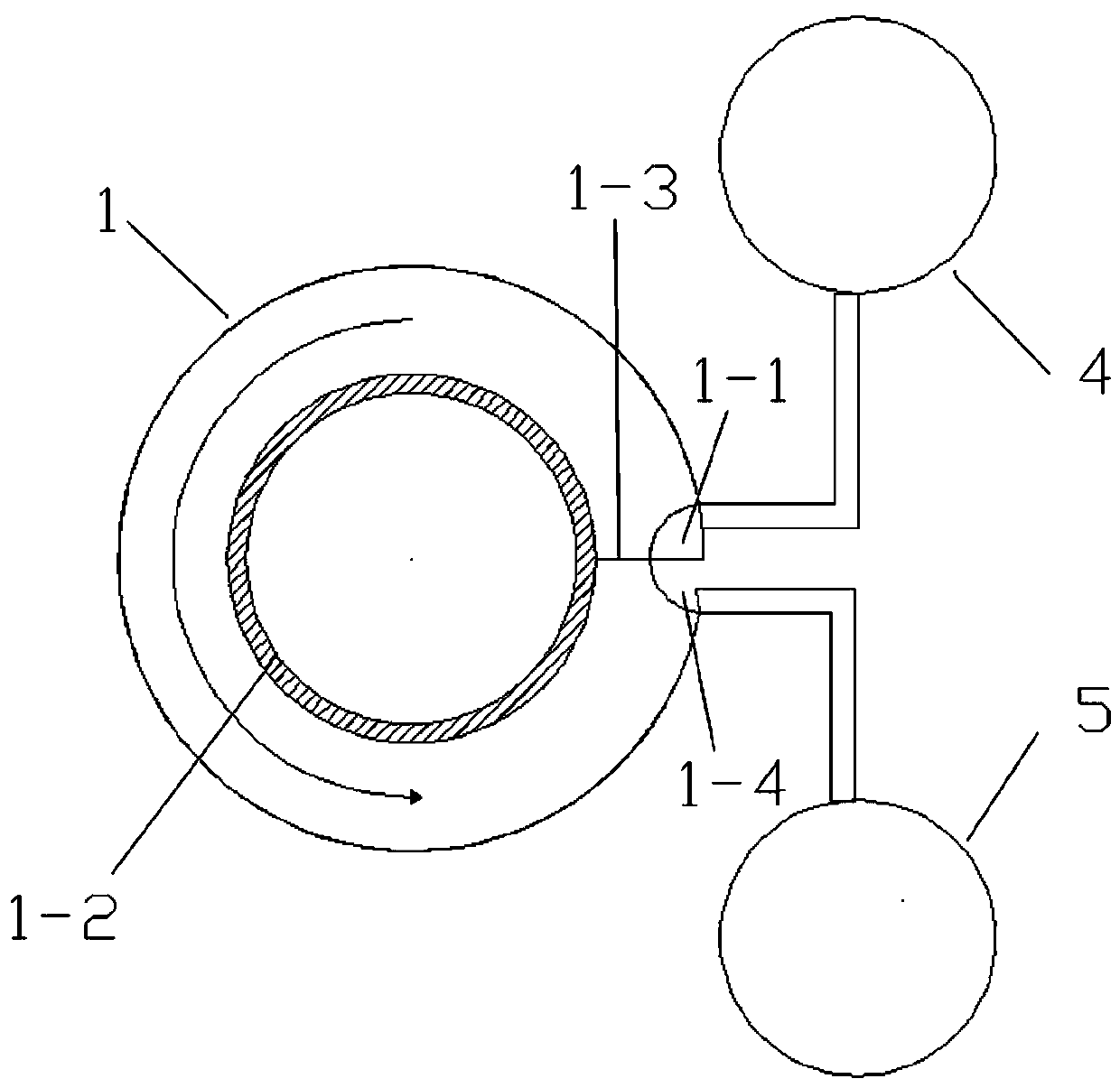

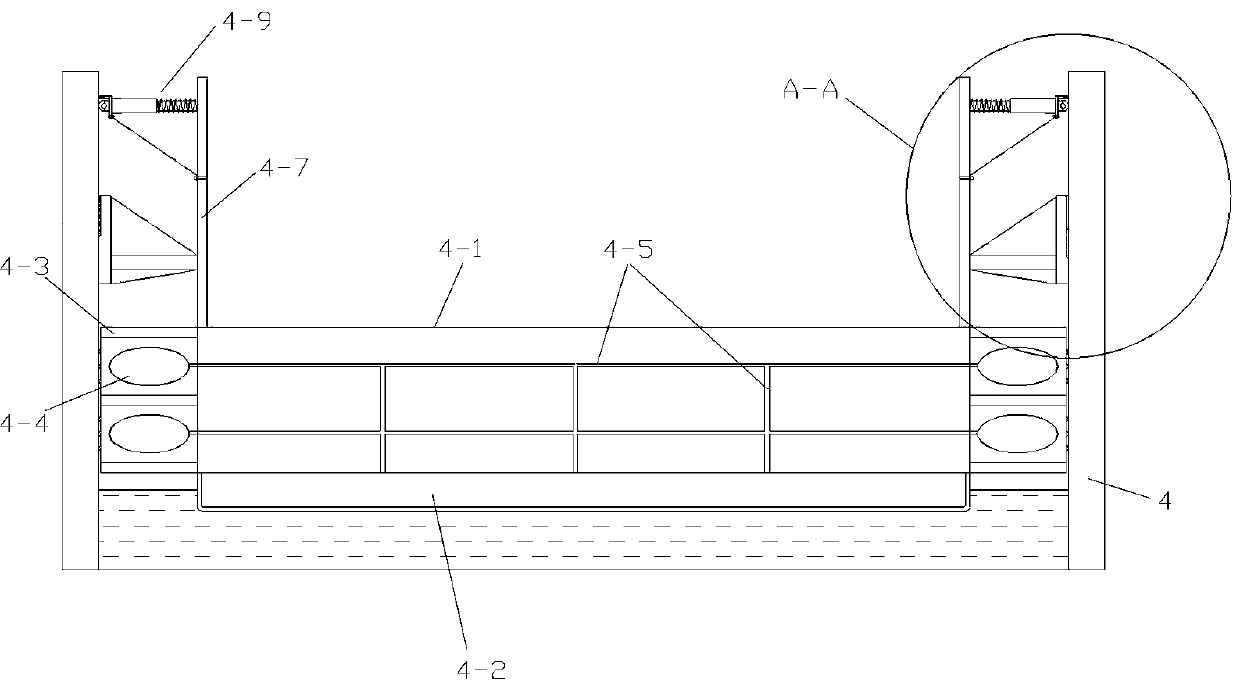

[0036] As shown in the figure: the embodiment of this scheme provides a biogas fermentation system, including a fermenter 1, a gas storage bag 2, a gas storage tank 3 and a biogas slurry storage tank 4, the fermenter 1 is a cylindrical tank structure, in One side wall of the fermenter 1 is provided with a feeding port 1-1 and a waste liquid discharge port 1-4, and an annular baffle 1-2 is arranged at the bottom of the fermenter 1 along the center, and the side wall of the fermenter 1 is connected to the annular baffle. A material circulation channel is formed between the baffles 1-2, and a partition plate 1-3 is provided at the feed port 1-1 in the material liquid flow channel to isolate the feed port 1-1 from the waste liquid discharge port 1-4 , the hei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com