Method for preparing benzaldehyde catalyst through catalytic oxidation of benzyl alcohol

A catalytic oxidation and catalyst technology, which is applied in catalyst activation/preparation, organic compound preparation, physical/chemical process catalysts, etc., can solve the problems of complex process and corrosive damage of reaction equipment, and achieves low cost of raw materials and a wide range of applications. Wide and controllable shell thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

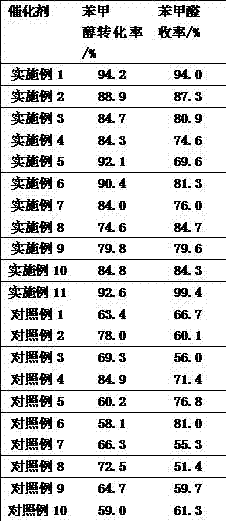

Examples

Embodiment 1

[0014] A kind of preparation method of benzaldehyde catalyst by catalytic oxidation of benzyl alcohol, the method comprises the following steps:

[0015] Step 1, 2molLa 2 o 3 @COF, 20mol propylene oxide, 1mol hydrochloric acid, 100mol deionized water, 20mol anhydrous

[0016] Ethanol was mixed evenly and stirred at 45°C for 60 minutes to obtain a clear transparent solution;

[0017] Step 2, add ammonia water to the above transparent solution to adjust the pH value of the mixed solution to 8.5, and continue to stir evenly at 50°C to obtain a colorless transparent solution; the obtained La 2 o 3 The @COF sol solution was poured into the mold and placed in a 50°C oven for 3 hours to obtain milky white La 2 o 3 @COF wet gel;

[0018] Step 3, add ethanol aging solution to the sample in the mold for aging treatment, replace the solvent 3 times, each time for 24 hours, and finally obtain milky white La 2 o 3 @COF alcohol gel;

[0019] Step 4, and then La 2 o 3 @COF alcohol...

Embodiment 2

[0024] Step 1, 1molLa 2 o 3 @COF, 2mol propylene oxide, 1mol hydrochloric acid, 100mol deionized water, 20mol anhydrous

[0025] Ethanol was mixed evenly at 45°C and stirred for 60 minutes to obtain a clear transparent solution; the rest of the steps were the same as in Example 1.

Embodiment 3

[0027] Step 1, the 4molLa 2 o 3 @COF, 1mol propylene oxide, 1mol hydrochloric acid, 100mol deionized water, 20mol anhydrous

[0028] Ethanol was mixed evenly at 45°C and stirred for 60 minutes to obtain a clear transparent solution; the rest of the steps were the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com