Preparation method of modified facing tiles for building materials

A decorative brick and modified technology, which is applied in the field of building decoration materials, can solve the problems of increasing fire hazards, aging and decomposition, and pulverization of facing bricks, and achieve the effects of eliminating smoke, improving flame retardancy, and small thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

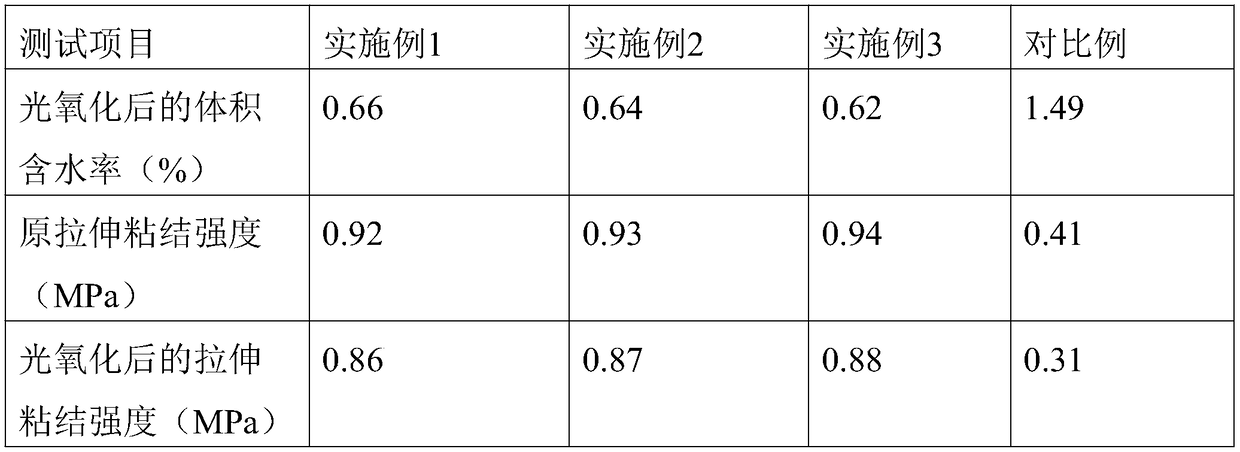

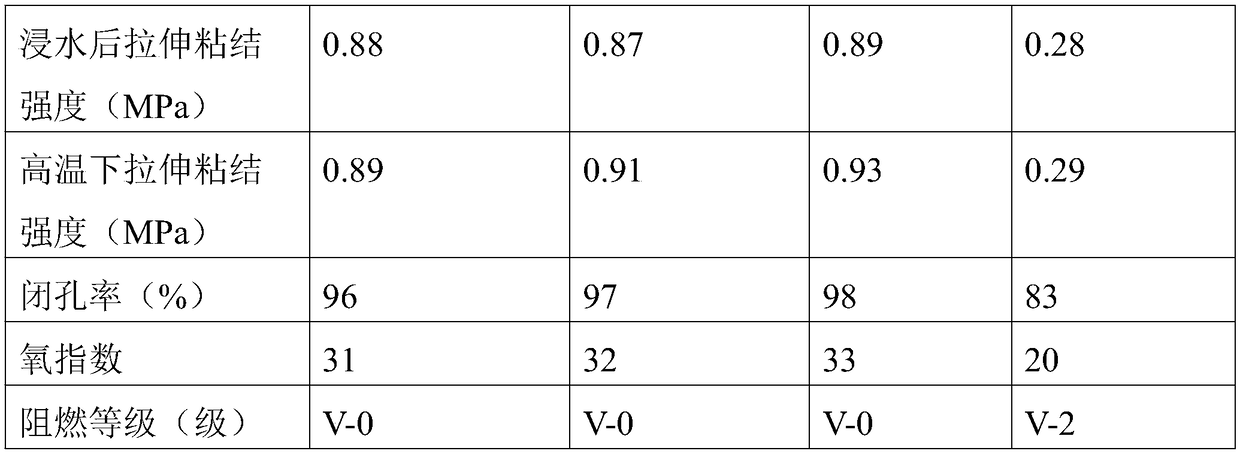

Examples

Embodiment 1

[0018] Mix stearic acid and deionized water in a beaker at a mass ratio of 1:4, heat up to 61°C, and stir for 20 minutes to obtain a stirred liquid, then mix magnesium hydroxide and aluminum hydroxide at a mass ratio of 1: 2 Mix and grind for 10 minutes to obtain a mixed powder, continue to mix the mixed powder and the stirring solution at a mass ratio of 3:1, and stir for 38 minutes at a speed of 185r / min, dry and discharge, and obtain a modified mixed powder; press Mix and soak attapulgite and deionized water at a mass ratio of 1:7 for 9 days to remove sediment and impurities, then put the soaked attapulgite into a muffle furnace and calcinate at a temperature of 360°C 1.5h, naturally cooled to room temperature, and the calcined attapulgite was ground for 12 minutes and passed through a 100-mesh sieve, and stored in bags to obtain pretreated attapulgite; pretreated attapulgite, sodium dodecylbenzenesulfonate Mix with deionized water at a mass ratio of 5:1:3 and place in an u...

Embodiment 2

[0020] Mix stearic acid and deionized water in a mass ratio of 1:4, place in a beaker, heat up to 63°C, and stir for 25 minutes to obtain a stirred liquid, then mix magnesium hydroxide and aluminum hydroxide in a mass ratio of 1: 2 Mix and grind for 10 minutes to obtain a mixed powder, continue to mix the mixed powder and the stirring solution at a mass ratio of 3:1, and stir for 41 minutes at a speed of 195 r / min, dry and discharge, and obtain a modified mixed powder; press Mix and soak attapulgite and deionized water at a mass ratio of 1:7 for 10 days to remove sediment and impurities, then put the soaked attapulgite into a muffle furnace and calcinate at a temperature of 390°C 1.5h, naturally cooled to room temperature, and the calcined attapulgite was ground for 14min and passed through a 100-mesh sieve, stored in bags to obtain pretreated attapulgite; pretreated attapulgite, sodium dodecylbenzenesulfonate Mix with deionized water at a mass ratio of 5:1:3 and place in an u...

Embodiment 3

[0022] Mix stearic acid and deionized water in a mass ratio of 1:4, place in a beaker, heat up to 65°C, and stir for 30 minutes to obtain a stirred liquid, then mix magnesium hydroxide and aluminum hydroxide in a mass ratio of 1: 2 Mix and grind for 11 minutes to obtain a mixed powder, continue to mix the mixed powder and the stirring solution at a mass ratio of 3:1, and stir for 45 minutes at a speed of 205 r / min, dry and discharge, and obtain a modified mixed powder; press Mix and soak attapulgite and deionized water at a mass ratio of 1:7 for 10 days to remove sediment and impurities, then put the soaked attapulgite into a muffle furnace and calcinate at a temperature of 410°C 2h, naturally cooled to room temperature, and the calcined attapulgite was ground for 15 minutes and passed through a 100-mesh sieve, and stored in bags to obtain pretreated attapulgite; pretreated attapulgite, sodium dodecylbenzenesulfonate and Deionized water was mixed with a mass ratio of 5:1:3 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com