Device and method for laser impact welding of metal foil plate based on intermediate layer automatic spraying

An automatic spraying and welding metal technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of little improvement in laser shock welding of dissimilar difficult-to-weld metals, and the limitation of the upper plate size and spot size, so as to achieve the welding process Stable, efficient and highly automated results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

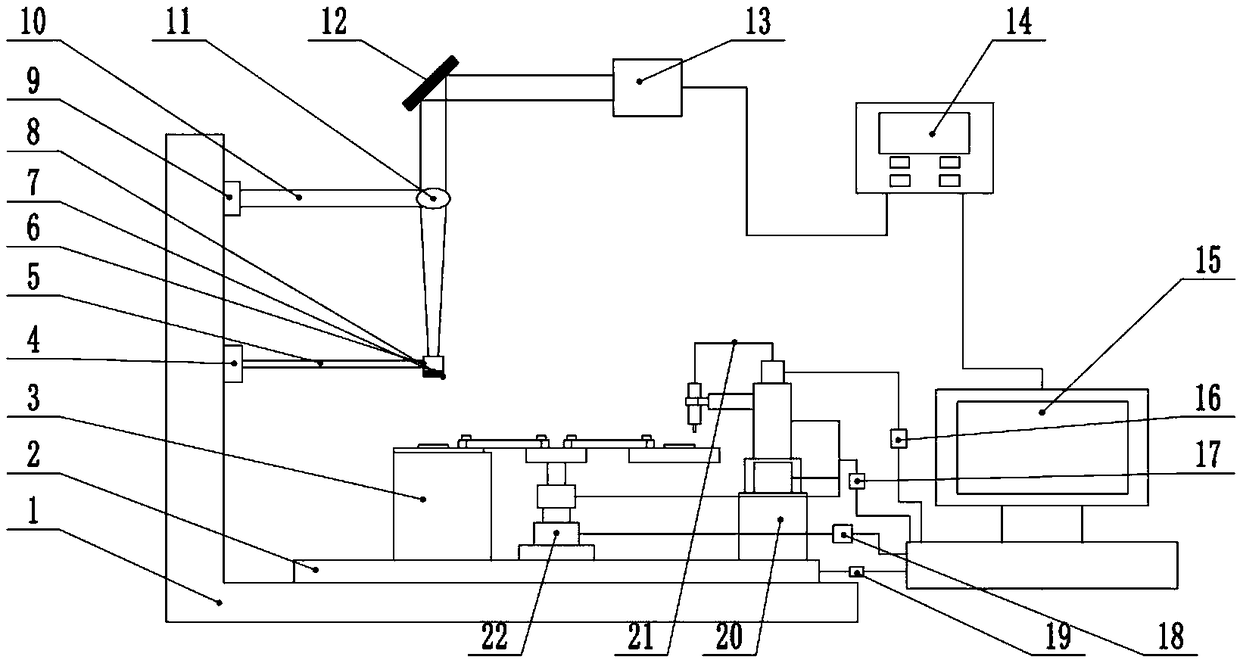

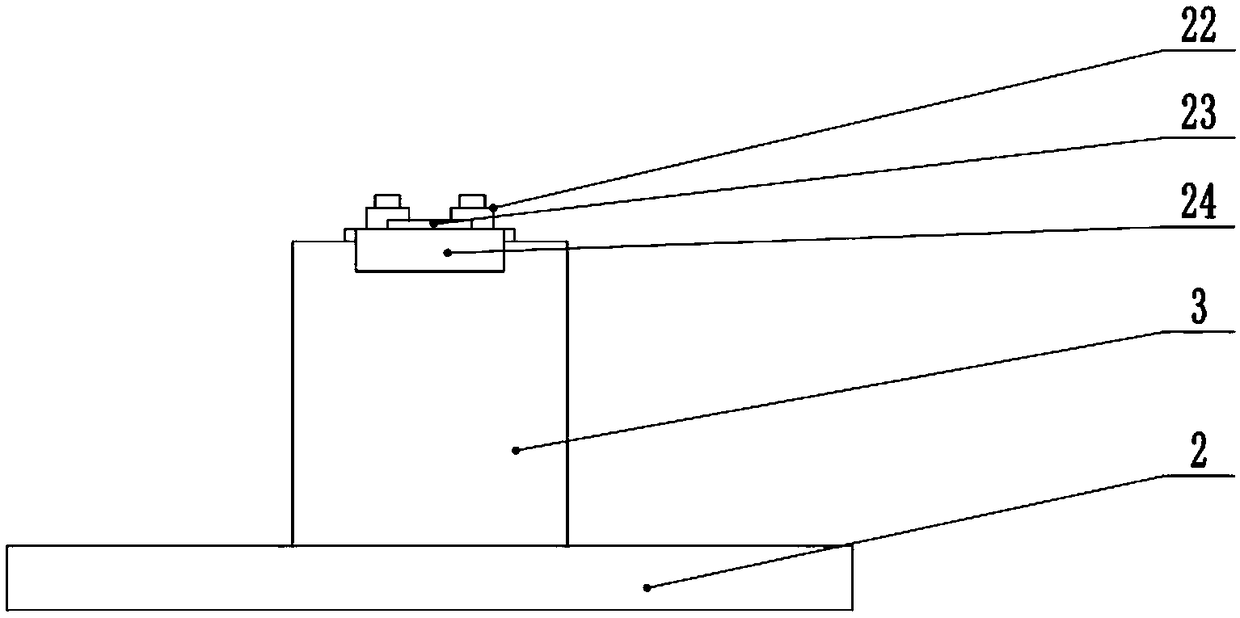

[0039] combined with figure 1 Shown is an embodiment of the device for laser shock welding of metal foil plates based on automatic spraying of the intermediate layer according to the present invention. The device includes a laser loading system, a control system, a placement conversion system, a welding system, and an automatic spraying of the intermediate layer. system and a three-dimensional mobile platform system; the middle layer spraying pen 37 in the middle layer automatic spraying system sprays the spraying liquid onto the substrate 23 on one side in the placement conversion system; the other side substrate 23 in the placement conversion system placed directly below the welding system; the laser beam emitted by the laser loading system is irradiated onto the constr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com