Production method of novel composite powder material containing superfine components

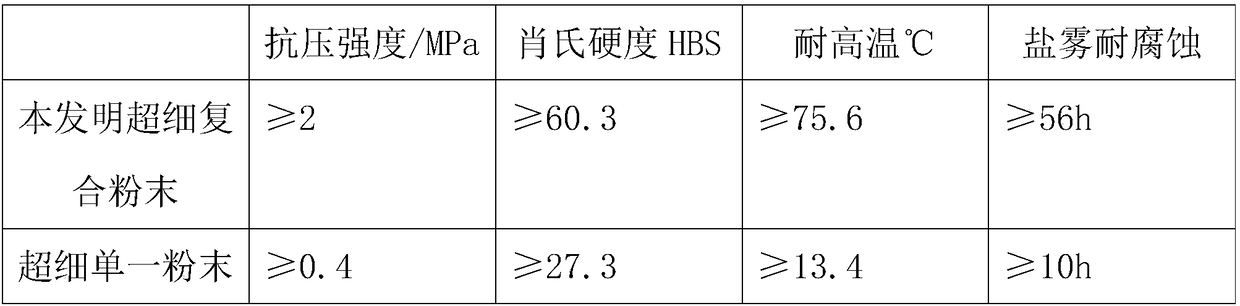

A composite powder and production method technology, applied in transportation and packaging, metal processing equipment, etc., can solve the problems of low surface smoothness of the used parts, affect the service life of the product, and low compressive and flexural resistance, and achieve excellent stability, Improvement of bending resistance and improvement of smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A production method for a novel composite powder material containing superfine components, made of the following materials in parts by weight: 8 parts by weight of cobalt, 15 parts by weight of titanium, 9 parts by weight of tungsten carbide, 11 parts by weight of chromium, 15 parts by weight of copper, and 12 parts by weight of steel parts by weight, 4 parts by weight of reducing agent, and 3 parts by weight of dispersant.

[0020] The specific production method is as follows:

[0021] Step 1: Mix glycerin, fatty acid, ethylene oxide, cetyl alcohol and triethylamine alcohol with water, and after preliminary mixing, send it into a high-temperature stirrer for heating and stirring to obtain an abrasive.

[0022] Step 2: Send cobalt, titanium, tungsten carbide, chromium, copper, and steel into the high-energy ball mill for grinding, add dispersant and the abrasive obtained in step 1 during the grinding process to prevent the agglomeration of particles, and change the grin...

Embodiment 2

[0032] A production method for a novel composite powder material containing superfine components, made of the following materials in parts by weight: 9 parts by weight of cobalt, 16 parts by weight of titanium, 9.5 parts by weight of tungsten carbide, 12.5 parts by weight of chromium, 17 parts by weight of copper, and 15 parts by weight of steel parts by weight, 5.5 parts by weight of reducing agent, and 4.5 parts by weight of dispersant.

[0033] The specific production method is as follows:

[0034] Step 1: Mix glycerin, fatty acid, ethylene oxide, cetyl alcohol and triethylamine alcohol with water, and after preliminary mixing, send it into a high-temperature stirrer for heating and stirring to obtain an abrasive.

[0035] Step 2: Send cobalt, titanium, tungsten carbide, chromium, copper, and steel into the high-energy ball mill for grinding, add dispersant and the abrasive obtained in step 1 during the grinding process to prevent the agglomeration of particles, and change ...

Embodiment 3

[0045] A production method for a novel composite powder material containing superfine components, made of the following materials in parts by weight: 10 parts by weight of cobalt, 17 parts by weight of titanium, 10 parts by weight of tungsten carbide, 14 parts by weight of chromium, 19 parts by weight of copper, and 18 parts by weight of steel parts by weight, 7 parts by weight of reducing agent, and 5 parts by weight of dispersant.

[0046] The specific production method is as follows:

[0047] Step 1: Mix glycerin, fatty acid, ethylene oxide, cetyl alcohol and triethylamine alcohol with water, and after preliminary mixing, send it into a high-temperature stirrer for heating and stirring to obtain an abrasive.

[0048] Step 2: Send cobalt, titanium, tungsten carbide, chromium, copper, and steel into the high-energy ball mill for grinding, add dispersant and the abrasive obtained in step 1 during the grinding process to prevent the agglomeration of particles, and change the gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com