Cu-doped manganese oxide octahedral molecular sieve catalyst and preparation method and application thereof

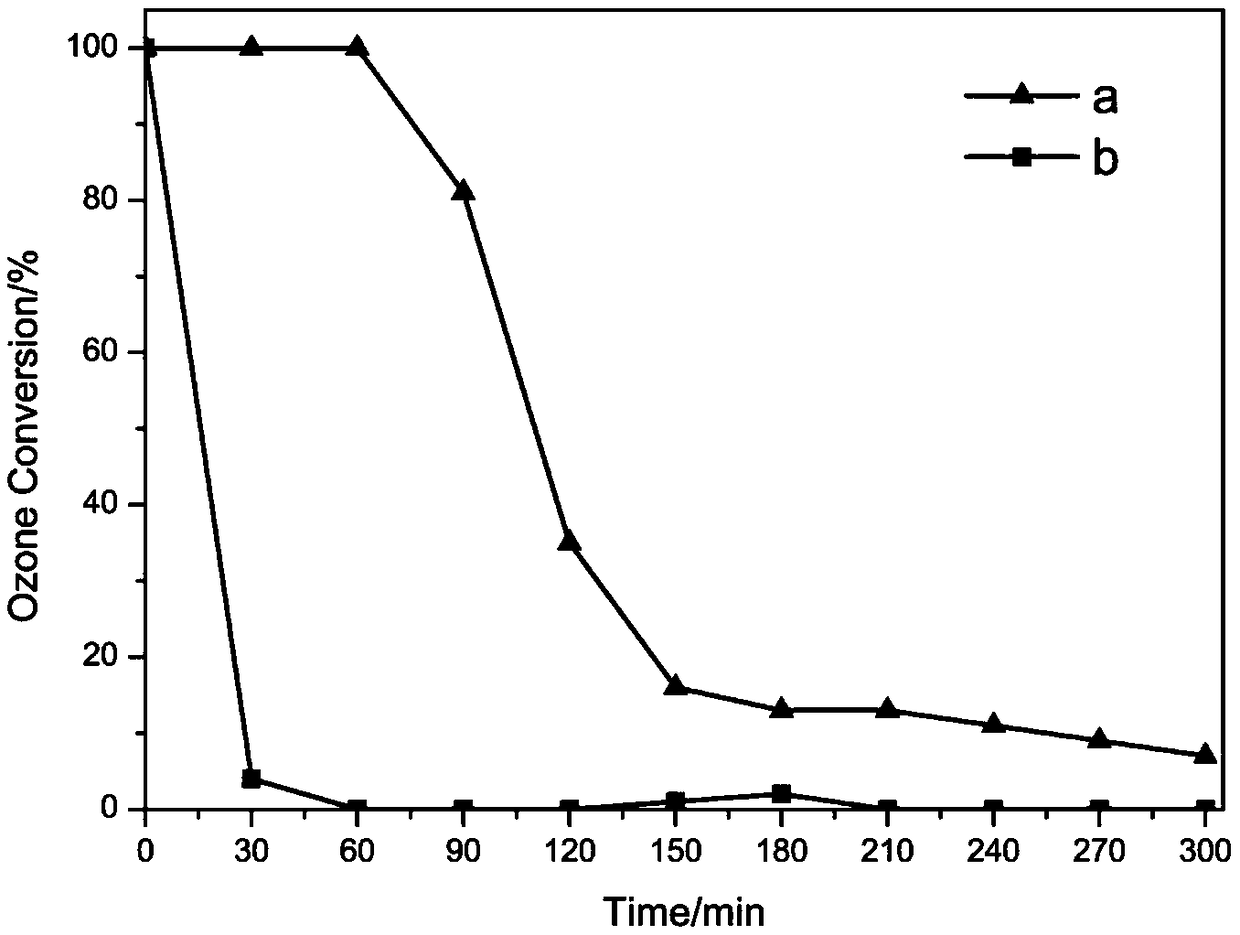

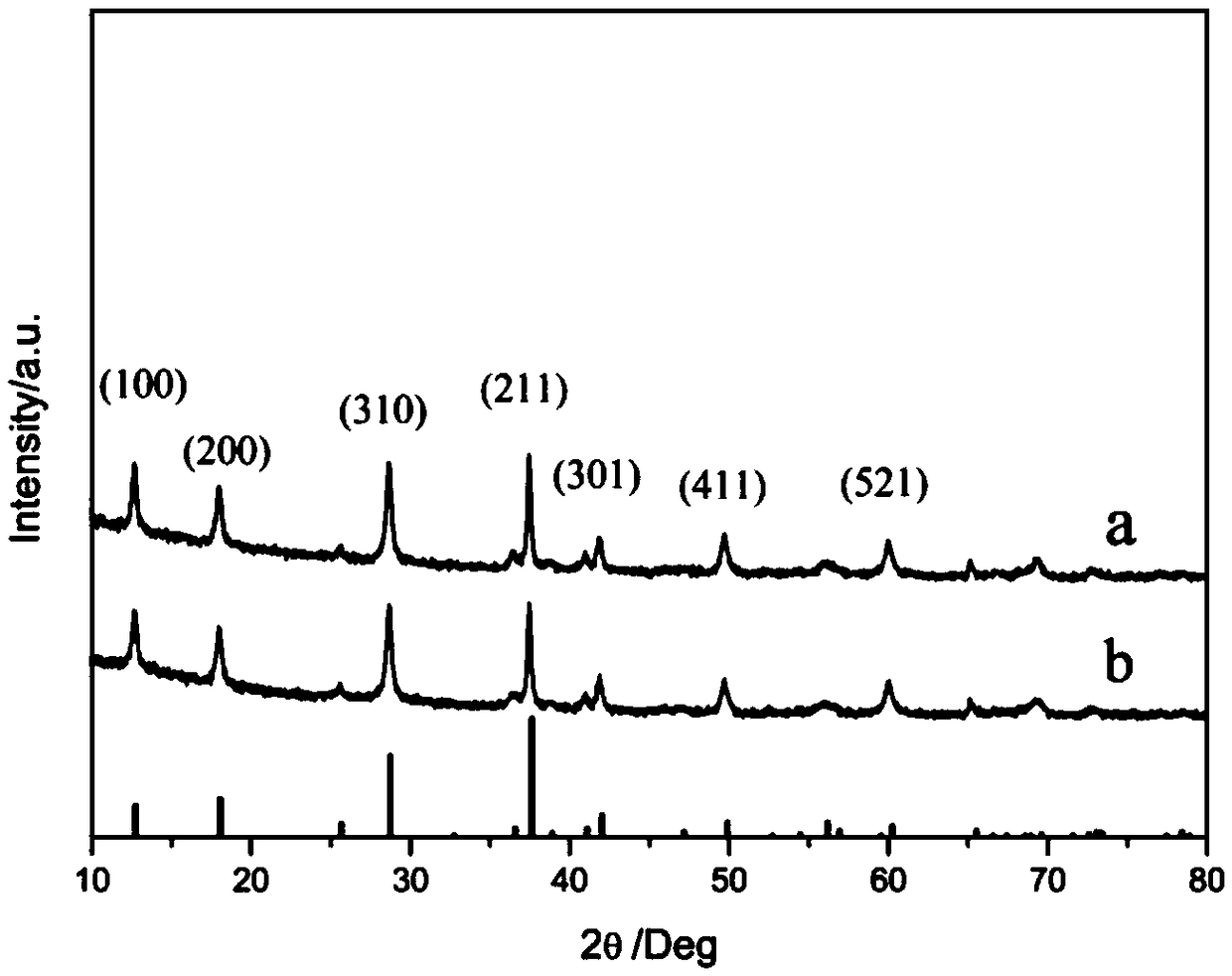

An octahedral molecular sieve, manganese oxide technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, separation methods, etc., can solve weak interactions, weakened OMS-2 catalyst influence, Reduce the activity and other problems, to achieve the effect of efficient ozone decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] In a first aspect, the present invention provides a method for preparing a copper-doped manganese oxide octahedral molecular sieve catalyst, comprising steps:

[0029] S1, dissolving divalent manganese salt in deionized water, adding an appropriate amount of nitric acid to adjust the pH value to 1-4, to obtain the first solution;

[0030] S2, dissolving permanganate in deionized water to obtain a permanganate solution, adding the obtained potassium permanganate solution dropwise to the first solution or adding the first solution dropwise to the permanganate In the potassium solution, a mixed solution was obtained after the dropwise addition;

[0031] S3, configure the metal component solution containing copper salt, the Cu in the metal component solution 2+ The molar ratio of the manganese ions in the mixed solution in step S2 is: 0.002-0.06, the metal component solution and the mixed solution in step 2 are added dropwise and mixed, and then refluxed at 100°C-140°C to ...

Embodiment 1

[0045] S1. At room temperature, put 1.352g of manganese sulfate monohydrate into a beaker, add 20mL of deionized water, stir and mix evenly, then add an appropriate amount of concentrated nitric acid, adjust the pH of the solution to 1, and keep stirring.

[0046] S2. Put 3.793 g of potassium permanganate in a beaker, add 60 mL of deionized water to prepare a potassium permanganate solution, and slowly add it dropwise to the solution obtained in S1. After the potassium permanganate solution is added dropwise, the mixed solution is transferred to the flask, and the copper doping is carried out by the previous doping method, and the mixed solution is added dropwise to the prepared metal component solution while stirring. Heated to 100°C and refluxed for 36h to obtain an intermediate.

[0047] S3. The intermediate obtained in S2 was washed with deionized water, and dried in an oven at 100° C. for 16 hours to obtain a black solid.

[0048] S4. Put the black solid obtained in S3 i...

Embodiment 2

[0050] S1. At room temperature, put 1.352g of manganese sulfate monohydrate into a beaker, add 20mL of deionized water, stir and mix evenly, then add an appropriate amount of concentrated nitric acid, adjust the pH of the solution to 2, and keep stirring.

[0051] S2. Put 3.793 g of potassium permanganate in a beaker, add 60 mL of deionized water to prepare a potassium permanganate solution, and then slowly drop it into the solution obtained in step 1. After the potassium permanganate solution is added dropwise, the mixed solution is transferred to the flask, and the copper doping is carried out by the previous doping method, and the mixed solution is added dropwise to the prepared metal component solution while stirring. Heated to 110°C and refluxed for 12h to obtain an intermediate.

[0052] S3. The product obtained in step 2 was washed with deionized water, and dried in an oven at 120° C. for 12 hours to obtain a black solid.

[0053] S4. Put the black solid obtained in st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com