Preparation method for oxygen-storage material with high thermal stability

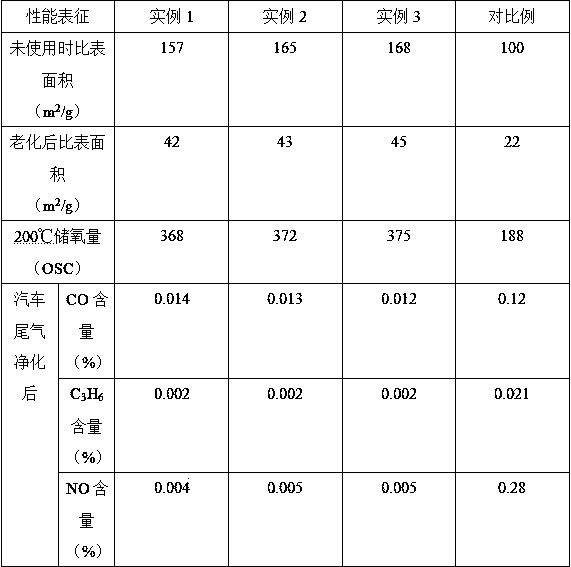

An oxygen storage material and stable technology, which is applied in the field of preparation of high thermally stable oxygen storage materials, can solve the problems of poor thermal stability, decreased oxygen storage/release capacity, low specific surface area, etc. The effect of improving the ability and increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In parts by weight, weigh 6 to 15 parts of lanthanum nitrate solution, 10 to 26 parts of cerium nitrate solution, 10 to 26 parts of zirconium nitrate solution, 10 to 16 parts of cyanuric acid, 50 to 60 parts of deionized water, 1 to 8 parts of 1.0mol / L sodium hydroxide solution, mix cyanuric acid and deionized water, stir at a constant temperature for 15-20min at a water bath temperature of 60-80°C, add lanthanum nitrate solution, cerium nitrate solution, zirconium nitrate solution, continue Stir for 1-2 hours to obtain a mixed liquid, add a sodium hydroxide solution with a concentration of 1.0mol / L, and continue to stir at a constant temperature for 30-60 minutes to obtain a composite liquid, filter while it is hot to obtain a filter residue, and use a deionized filter with a temperature of 60-80°C Wash with water for 3 to 5 times, dehydrate, place in an oven at 60 to 80°C, dry to constant weight, and cool to room temperature to obtain the precursor of the oxygen storag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com