Three dimensional (3D) printed PCL-PDA-AgNPs scaffold for anti-infective bone tissue engineering as well as preparation method and application of 3D printed PCL-PDA-AgNPs scaffold

A technology of bone tissue engineering and 3D printing, applied in tissue regeneration, additive processing, medical science, etc., can solve the problems of high price, immune rejection of bioactive factors, low processing performance, etc., and improve hydrophilicity and biophase Capacitance, promotion of new bone tissue formation, beneficial effect of exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

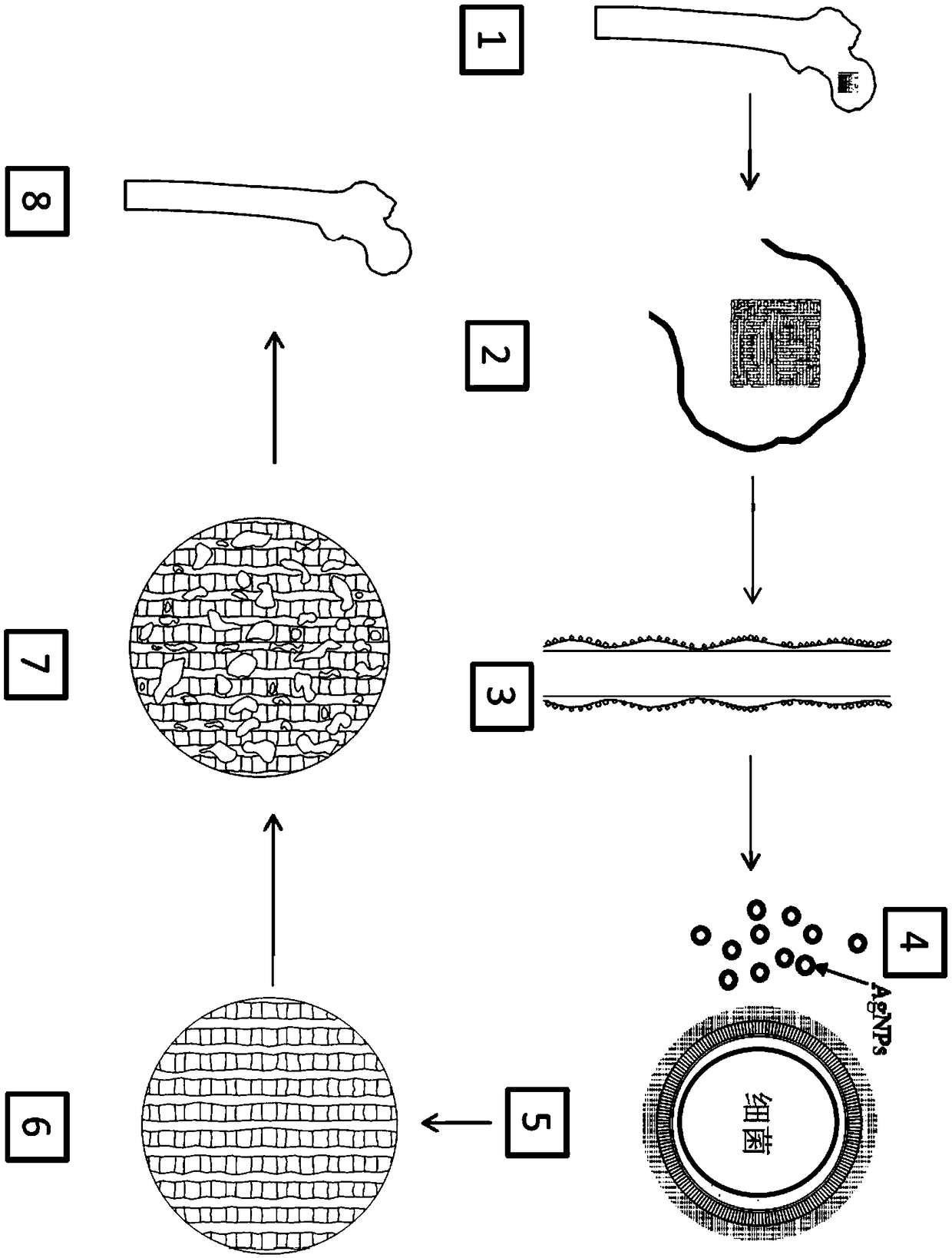

[0043] A 3D printing PCL-PDA-AgNPs anti-infection bone tissue engineering scaffold, which is prepared by the following method:

[0044] Step 1: Prepare 3D printed PCL scaffold

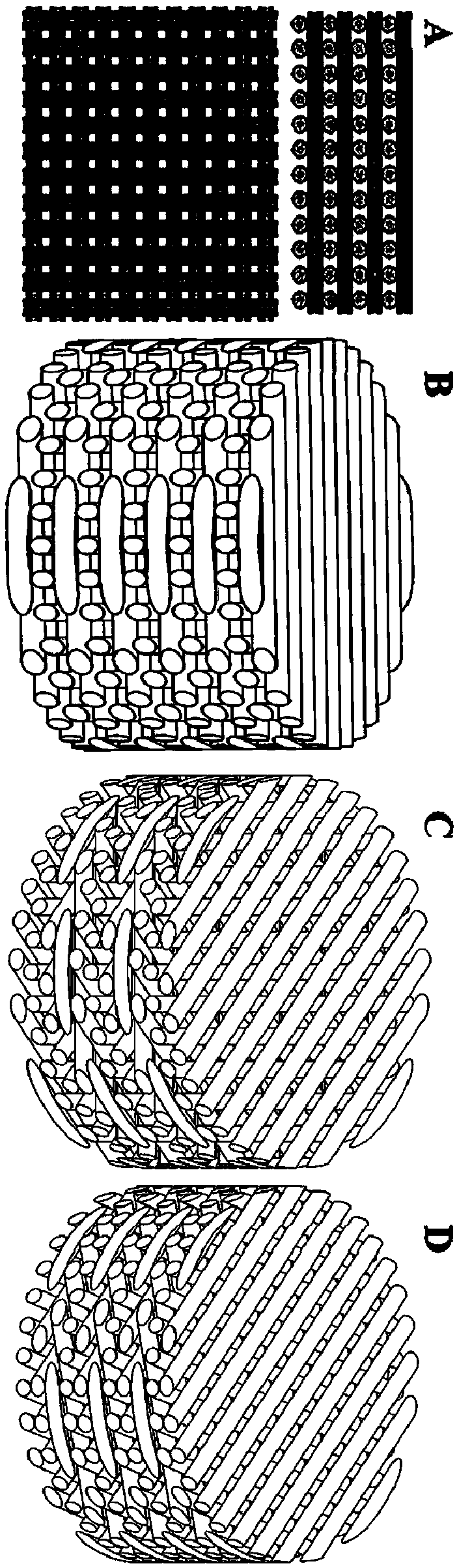

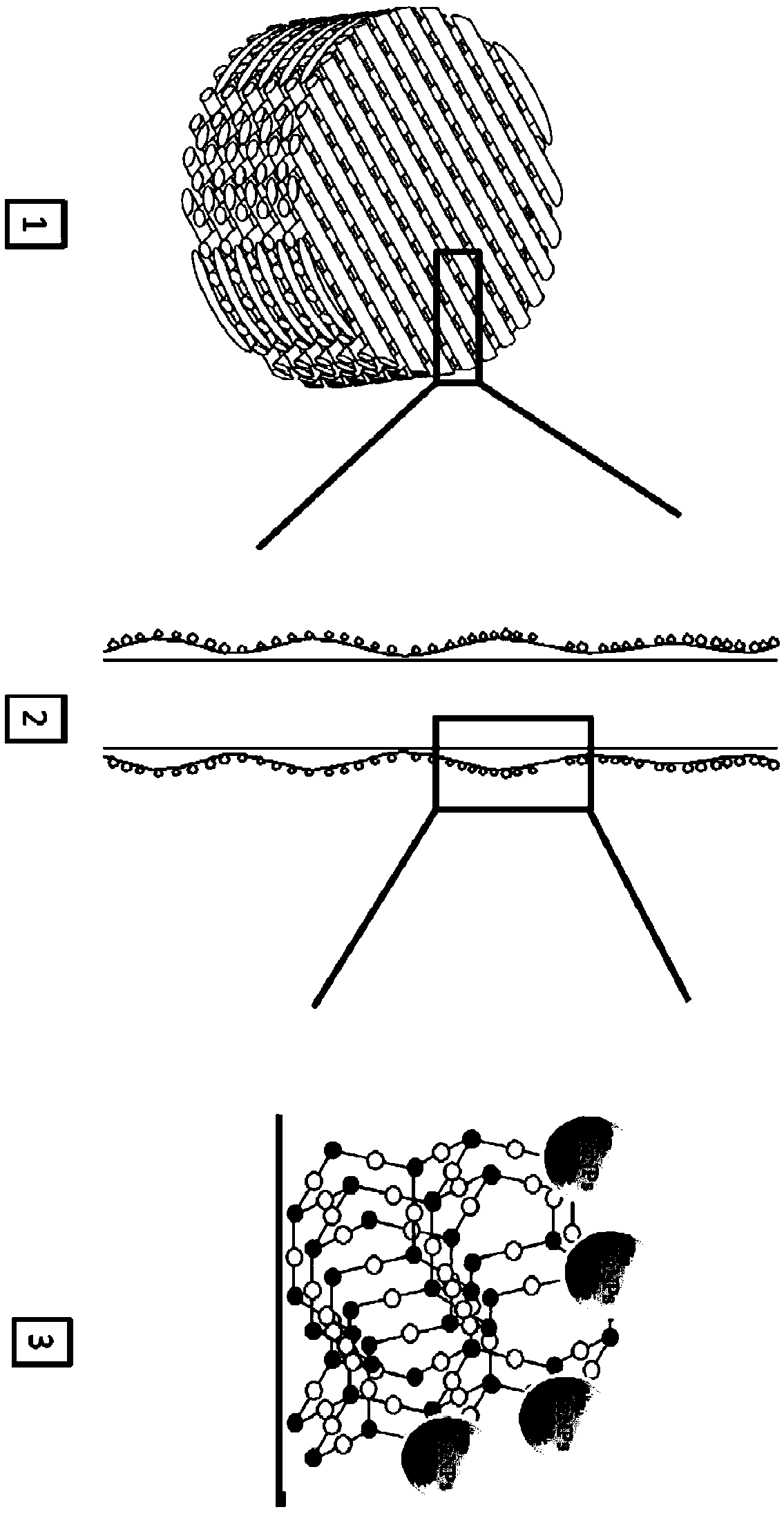

[0045] Such as figure 1 As shown in (A), the PCL is heated to a liquid state through the heating system of the melt-extruded 3D printing, extruding the molded fiber bundles, and obtaining the 3D scaffold PCL by superimposing and arranging different layers of the fiber bundles;

[0046] Step 2: Prepare 3D printed PCL-PDA bracket

[0047] Dissolve 0.61g Tris in 500mL water, then add HCL to adjust the pH of the system to 8-9, and prepare a Tris-HCL solution; dissolve 1g dopamine in the Tris-HCL solution, stir to dissolve, and configure it as a DA-Tris-HCL solution ;Add the 3D scaffold PCL to the DA-Tris-HCl solution, stir under the condition of avoiding light, and take out the scaffold after the DA self-polymerizes on the surface of the PCL to form PDA, and obtain the 3D printed PCL-PDA scaffold;

[00...

Embodiment 2

[0051] A 3D printing PCL-PDA-AgNPs anti-infection bone tissue engineering scaffold, which is prepared by the following method:

[0052] Step 1: Prepare 3D printed PCL scaffold

[0053] Such as figure 1 As shown in (B), the PCL is heated to a liquid state through the heating system of the melt-extruded 3D printing, and the molded fiber bundle is extruded, and the 0-90° stacked arrangement of the fibers is a square-pore 3D support PCL;

[0054] Step 2: Prepare 3D printed PCL-PDA bracket

[0055] Dissolve 0.4g Tris in 500mL water, then add HCL to adjust the pH value of the system to 8-9, and prepare a Tris-HCL solution; dissolve 1g dopamine in the Tris-HCL solution, stir to dissolve, and configure it as a DA-Tris-HCL solution ;Add the 3D scaffold PCL to the DA-Tris-HCl solution, stir under the condition of avoiding light, and take out the scaffold after the DA self-polymerizes on the surface of the PCL to form PDA, and obtain the 3D printed PCL-PDA scaffold;

[0056] Step 3: P...

Embodiment 3

[0059] A 3D printing PCL-PDA-AgNPs anti-infection bone tissue engineering scaffold, which is prepared by the following method:

[0060] Step 1: Prepare 3D printed PCL scaffold

[0061] Such as figure 1 As shown in (C), the PCL is heated to a liquid state through the heating system of the melt-extruded 3D printing, and the molded fiber bundles are extruded, and the fiber bundles are stacked at 0-60-120-180° to obtain a 3D scaffold PCL;

[0062] Step 2: Prepare 3D printed PCL-PDA bracket

[0063] Dissolve 0.8g Tris in 500ml of water, then add HCL to adjust the pH of the system to 8-9, and prepare a Tris-HCL solution; dissolve 1g of dopamine in the Tris-HCL solution, stir to dissolve, and configure it as a DA-Tris-HCL solution ;Add the 3D scaffold PCL to the DA-Tris-HCl solution, stir under the condition of avoiding light, and take out the scaffold after the DA self-polymerizes on the surface of the PCL to form PDA, and obtain the 3D printed PCL-PDA scaffold;

[0064] Step 3: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com