Composite separator, process for preparing the same, and lithium-sulfur battery comprising the same

A composite diaphragm and diaphragm technology, applied in the direction of lithium batteries, battery pack components, non-aqueous electrolyte batteries, etc., can solve problems such as weak physical force, damage to battery performance, and reduced conductivity of the modified layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

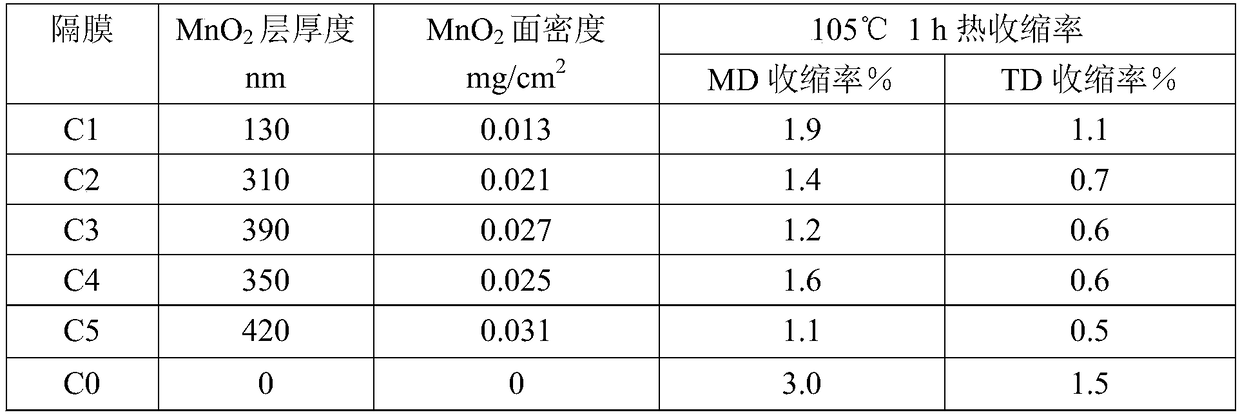

Embodiment 1

[0056] At room temperature, 7.9g KMnO 4 Add the powder into 100g of water and configure 0.5mol / L of KMnO 4 solution. Using a polyethylene diaphragm as the base film, a 10×10 cm base film sample was soaked in the KMnO 4 solution, and placed in a blast drying oven at a temperature of 40°C, soaking for 1 day. After the completion, the separator was repeatedly rinsed with deionized water, and dried in a blast drying oven at 50°C for 10 hours to obtain the composite MnO for lithium-sulfur batteries. 2 @PE diaphragm (C1).

Embodiment 2

[0058] At room temperature, 7.9g KMnO 4 Add the powder into 100g of water and configure 0.5mol / L of KMnO 4 solution. Using a polyethylene diaphragm as the base film, a 10×10 cm base film sample was soaked in the KMnO 4 solution, and placed in a blast drying oven at a temperature of 50°C, soaking for 1 day. After the completion, the separator was repeatedly rinsed with deionized water, and dried in a blast drying oven at 50°C for 10 hours to obtain the composite MnO for lithium-sulfur batteries. 2 @PE diaphragm (C2).

Embodiment 3

[0060]At room temperature, 7.9g KMnO 4 Add the powder into 100g of water and configure 0.5mol / L of KMnO 4 solution. Using a polyethylene diaphragm as the base film, a 10×10 cm base film sample was soaked in the KMnO 4 solution, and placed in a blast drying oven at a temperature of 60°C, soaking for 1 day. After the completion, the separator was repeatedly rinsed with deionized water, and dried in a blast drying oven at 50°C for 10 hours to obtain the composite MnO for lithium-sulfur batteries. 2 @PE diaphragm (C3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com