A silicon carbide Schottky diode with high withstand voltage and a method for manufacturing the same

A technology of Schottky diodes and manufacturing methods, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problem of reduced withstand voltage efficiency, increase the forward conduction voltage drop of devices, and reduce the current conduction area of devices and other problems, to achieve the effect of reducing the forward voltage drop and reducing the electric field strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

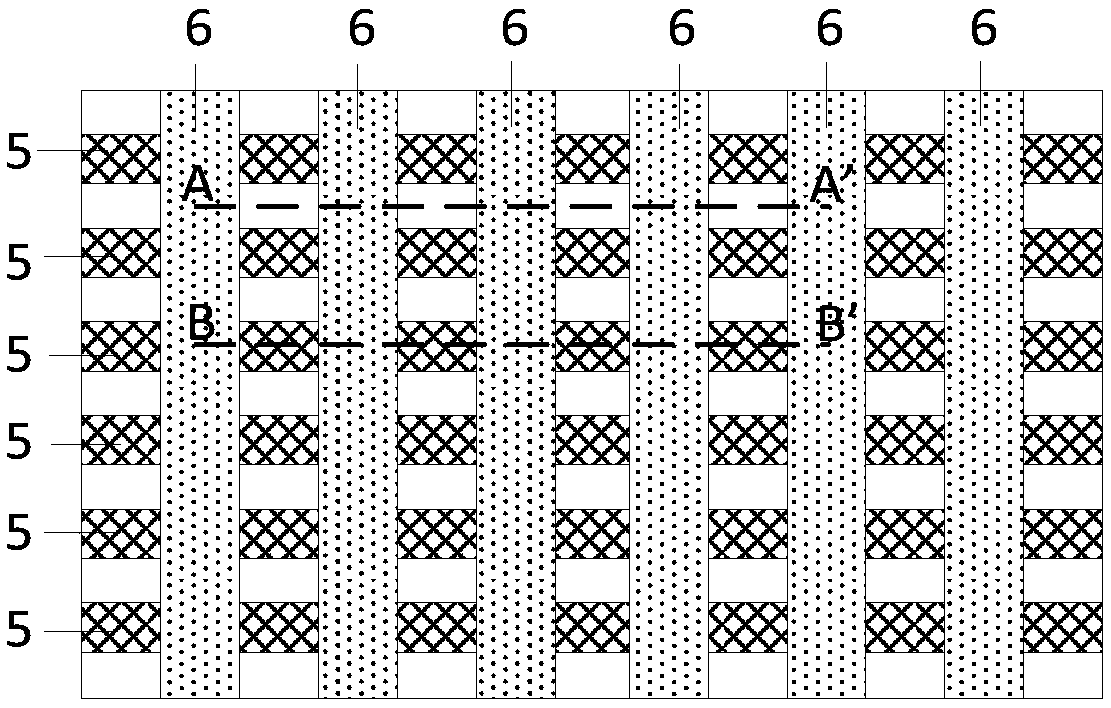

[0035] Embodiment 1: as figure 2As shown, a high withstand voltage silicon carbide Schottky diode is provided, including a semiconductor substrate, and the semiconductor substrate includes an N-type silicon carbide substrate 2 and an N-type silicon carbide epitaxial layer on the N-type silicon carbide substrate 2 3. In the cross-sectional direction of the device, a cathode metal 1, an N-type silicon carbide substrate 2, an N-type silicon carbide epitaxial layer 3, and an anode metal 8 are sequentially arranged from bottom to top, and in the N-type silicon carbide epitaxial layer 3 The upper part is provided with several strip-shaped first P-type well regions 6 separated at intervals and strip-shaped first N-type well regions 7 between adjacent strip-shaped first P-type well regions 6. The anode metal 8 and the The strip-shaped first N-type well region 7 is in Schottky contact, and the anode metal 8 is in ohmic contact with the strip-shaped first P-type well region 6; a cathod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com