ZK60 magnesium alloy heat treatment process and performance study thereof,

A magnesium alloy and process technology, which is applied in the field of ZK60 magnesium alloy heat treatment process and its performance research, can solve the problems of lack of research on new high-strength deformed magnesium alloy ZK60 heat treatment process, and achieve the effect of improving plasticity and widening the application field.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1) Determination of heat treatment process parameters:

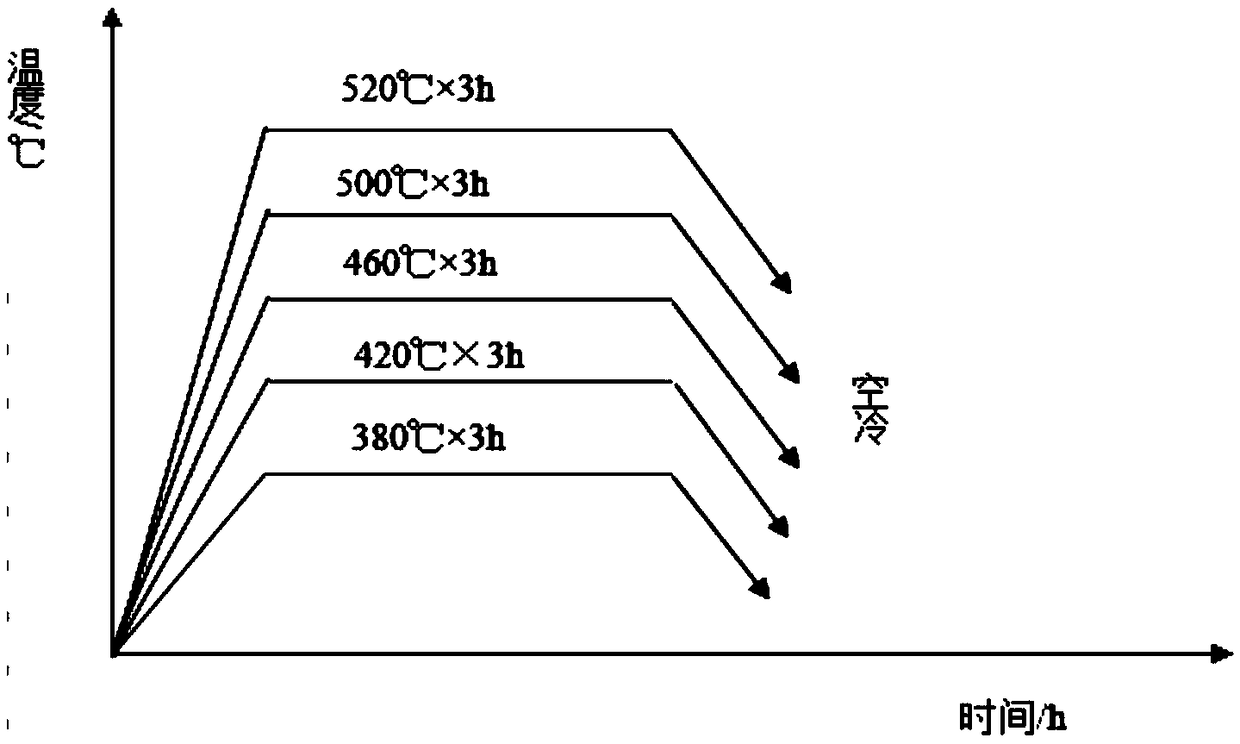

[0041]From the research results of the as-cast microstructure of ZK60 magnesium alloy, it can be seen that there are a large number of eutectic structures in the grain boundaries and dendrite boundaries, and the Zn-rich phase is the main one. It can be speculated that the segregation of Zn element at the grain boundary will inevitably reduce its solid solubility in the matrix, thereby affecting the performance of the material. At the same time, ZK60 magnesium alloy is also an alloy material that can be strengthened by heat treatment. For this reason, solid solution and aging treatment under various conditions were carried out in experiments to study the changes in mechanical properties and precipitated phases of alloys under various heat treatment processes, so as to select the best heat treatment plan and obtain the best service structure and mechanical properties. performance. figure 1 is the phase diagram of ...

Embodiment 2

[0047] The mass fractions (%) of the main elements of the ZK60 magnesium alloy in the examples are shown in Table 1.

[0048] Table 1 Mass fraction of main elements in ZK60 magnesium alloy (%)

[0049] element

Zn

Zr

Impurities

Mg

4.8-6.2

>0.45

<0.30

margin

[0050] Other impurity elements such as Fe, Ni, Cu, and Co have a very small solid solubility in magnesium, and when the mass fraction of the concentration is less than 0.2%, it will have a very harmful effect on the corrosion resistance of Mg, and serious damage will occur. Galvanic corrosion accelerates the corrosion of Mg. Ni often forms Mg with magnesium 2 Intermetallic compounds such as Ni are distributed in the grain boundary in the form of a network, which reduces the corrosion resistance of magnesium. When the Ni content is greater than 0.016%, the corrosion rate of the magnesium alloy is significantly accelerated. Fe is insoluble in solid magnesium,...

Embodiment 3

[0060] Performance Testing:

[0061] 1. Microhardness analysis, the test force (load) is 9.8N, and the holding time is 15s;

[0062] 2. Metallographic analysis: metallographic observation of the metallographic structure of the alloy under various heat treatment states, the uniformity of the as-cast structure, the shape, size, quantity and distribution of the precipitated phase of the material after heat treatment, so as to qualitatively explain Material properties.

[0063] 3. X-Ray diffraction analysis: scanning angle: 30°~80°; scanning speed: 5° / min; target material: Cu target; accelerating voltage: 40KV; filament current: 200mA; graphite monochromator filter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com