Application of sago as pore former, pore former and method for preparing foam metal through pore former

A foam metal and pore-forming agent technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of poor pore-forming effect, difficult to remove, high cost of pore-forming agent, etc., and achieve low price, low equipment requirements, cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1 adopts technical scheme of the present invention to prepare foamed steel

[0045] Prepare foam steel according to the following steps:

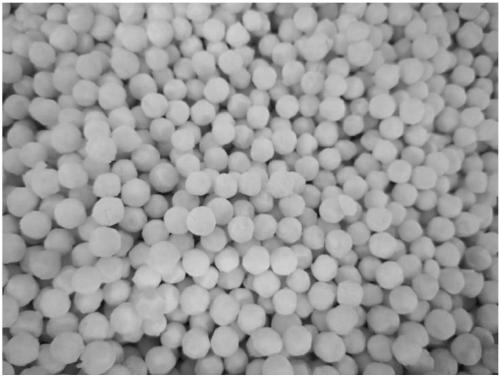

[0046]A. Put titanium powder with a particle size of 200 mesh and a purity of 99.9% and spherical sago particles with a particle size of about 4mm at a volume fraction of 2:3, and put them into a V-type mixer and mix them for 1 hour; during the mixing process, add Absolute ethanol, the mass ratio of absolute ethanol and the mixture is 5:95.

[0047] B. Put the uniformly mixed powder into a steel mold and compact it into a billet. The one-way pressure is 200Mpa, the holding time is 5min, and the mold is demoulded and dried.

[0048] C. Pre-sinter the dry blank, in the atmosphere of high-purity argon, raise it to 550°C at a rate of 10°C / min, and keep it for 21 hours. Next, raise it to 1000°C at the same rate, keep it for 2 hours, and cool with the furnace , to obtain foamed steel with a pore size of 3.6mm and a porosity of...

Embodiment 2

[0049] Embodiment 2 adopts technical scheme of the present invention to prepare foamed titanium

[0050] Foam titanium is prepared according to the following steps:

[0051] A. Put titanium powder with a particle size of 100 mesh and a purity of 99.9% and spherical sago particles with a particle size of about 0.2mm at a volume fraction of 3:7, and mix them in a V-type mixer for 1 hour; during the mixing process Add dehydrated ethanol, the mass ratio of dehydrated ethanol and mixture is 4:96.

[0052] B. Put the uniformly mixed powder into a steel mold and compact it into a billet. The one-way pressure is 200Mpa, the holding time is 4min, and the mold is demoulded and dried.

[0053] C. Pre-sinter the dry billet, in the atmosphere of high-purity argon, raise it to 520°C at a rate of 7°C / min, keep it for 3 hours, and then raise it to 1200°C at the same rate, keep it for 2 hours, and cool with the furnace A titanium foam with a pore diameter of 0.15 mm and a porosity of 73.26% ...

Embodiment 3

[0054] Embodiment 3 adopts technical scheme of the present invention to prepare foamed copper

[0055] Prepare foamed copper according to the following steps:

[0056] A. Put the copper powder with a particle size of 300 mesh and a purity of 99.9% and spherical sago particles with a particle size of about 0.3mm at a volume fraction of 1:4, and put them into a V-shaped mixer and mix them for 1 hour; during the mixing process Add absolute ethanol, and the mass ratio of absolute ethanol and the mixture is 3:97.

[0057] B. Put the uniformly mixed powder into a steel mold and compact it into a billet. The one-way pressure is 100Mpa, the holding time is 3min, and the mold is demoulded and dried.

[0058] C. Pre-sinter the dry billet, raise it to 480°C at a rate of 4°C / min in a high-purity argon atmosphere, and keep it for 1 hour. Next, raise it to 900°C at the same rate, hold it for 2 hours, and cool it with the furnace. A copper foam with a pore diameter of 0.25mm and a porosity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com