High-performance hydrogenated nitrile butadiene rubber complex and preparation method thereof

A hydrogenated nitrile rubber and rubber compound technology, which is applied in the field of high-performance hydrogenated nitrile butadiene rubber compound and its preparation, can solve the problems of short service life, narrow application range of working environment, difficult to meet strict mechanical properties, etc., to achieve Good economic benefits, good dispersibility, good oil resistance and high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

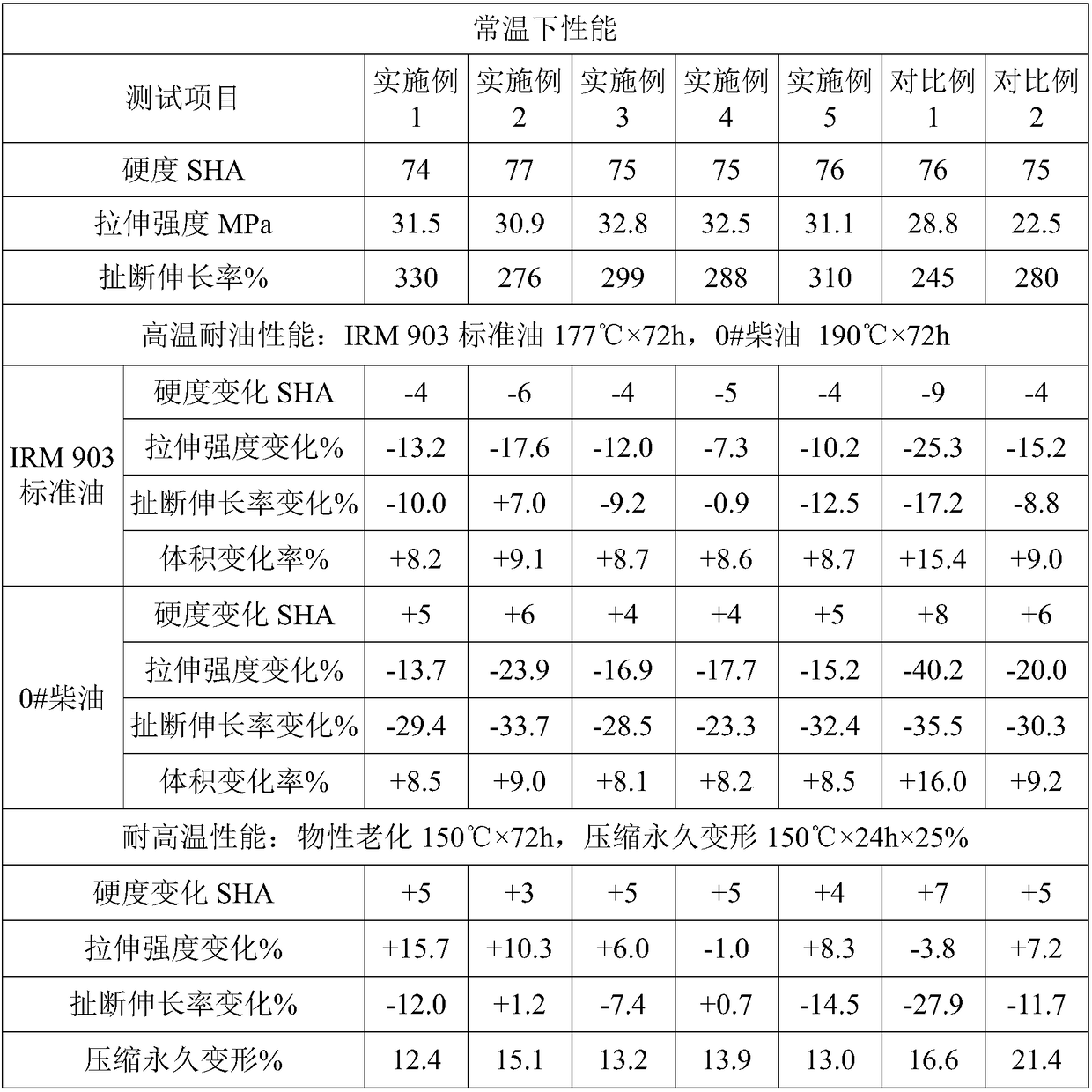

Examples

Embodiment 1

[0052] Prepare high-performance raw materials for the preparation of hydrogenated nitrile-butadiene-based rubber compounds, which include the following raw material components in parts by weight: 70 parts of hydrogenated nitrile-butadiene rubber, 30 parts of composite masterbatch, 1 part of stearic acid, 40 parts of N220, 3 parts of Plastic agent TOTM, 1 part of anti-aging agent MBZ2, 1 part of anti-aging agent 445, 3 parts of vulcanizing agent DCP, 1 part of triallyl isocyanurate TAIC.

[0053] Preparation of Hydrogenated Nitrile-Based Rubber Compounds:

[0054] S 1 , mixing of composite masterbatch: 55% by weight of Zannan Hydrogenated nitrile butadiene rubber is dropped in the banbury mixer, masticating 1.5min; Then open top bolt, drop into the nano-zinc oxide of 20% weight part in the banbury mixer, the carbon nanotube of 10% weight part, the aromatic powder of 15% weight part Close the top bolt and continue mixing for rayon pulp. Mix for 8 minutes. When the temperature...

Embodiment 2

[0061] Prepare high-performance raw materials for the preparation of hydrogenated nitrile-butadiene-based rubber compounds, which include the following raw material components in parts by weight: 100 parts of hydrogenated nitrile-butadiene rubber, 15 parts of composite masterbatch, 2 parts of stearic acid, 25 parts of N220, 30 parts of N550 , 20 parts of N990, 10 parts of plasticizer TOTM, 2 parts of antioxidant MBZ2, 2 parts of antioxidant 445, 1.5 parts of antioxidant MB, 11 parts of F-40, 1 part of DCP, 2 parts of triallyl isocyanuric Ester TAIC, 1 part PDM.

[0062] Preparation of Hydrogenated Nitrile-Based Rubber Compounds:

[0063] S 1 , mixing of composite masterbatch: 35% by weight of Zannan Hydrogenated nitrile butadiene rubber is put into the banbury mixer, mastication 1.5min; Then open the top bolt, drop into the nano-zinc oxide of 25% weight part in the banbury mixer, the carbon nanotube of 20% weight part, the carbon nanotube of 20% weight part Close the top b...

Embodiment 3

[0070] Prepare high-performance raw materials for the preparation of hydrogenated nitrile-butadiene-based rubber compounds, which include the following raw material components in parts by weight: 95 parts of hydrogenated nitrile-butadiene rubber, 20 parts of composite masterbatch, 1.5 parts of stearic acid, 50 parts of N220, 7 parts of Plasticizer TOTM, 2 parts of antioxidant MBZ2, 1.5 parts of antioxidant 445, 10 parts of F-40, 2 parts of triallyl isocyanurate TAIC.

[0071] Preparation of Hydrogenated Nitrile-Based Rubber Compounds:

[0072] S 1 , mixing of composite masterbatch: 40% by weight of Zannan Hydrogenated nitrile butadiene rubber is dropped in the banbury mixer, masticating 1.5min; Then open the top bolt, drop into the nano-zinc oxide of 23% weight part in the banbury mixer, the carbon nanotube of 15% weight part, the carbon nanotube of 22% weight part Close the top bolt and continue mixing for aramid pulp. Mix for 8 minutes. When the temperature in the interna...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com