Hard bone liquefaction equipment and method for synchronously producing bone collagen polypeptides and ultrafine bone powder

A collagen and hard technology, applied in the liquefaction equipment of hard bone, co-production of collagen polypeptide and ultrafine bone meal, co-production of polypeptide and bone meal, liquefaction equipment field, can solve the problem of water consumption and energy consumption, high production cost , large equipment investment and other problems, to achieve the effect of increasing the area, high safety, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

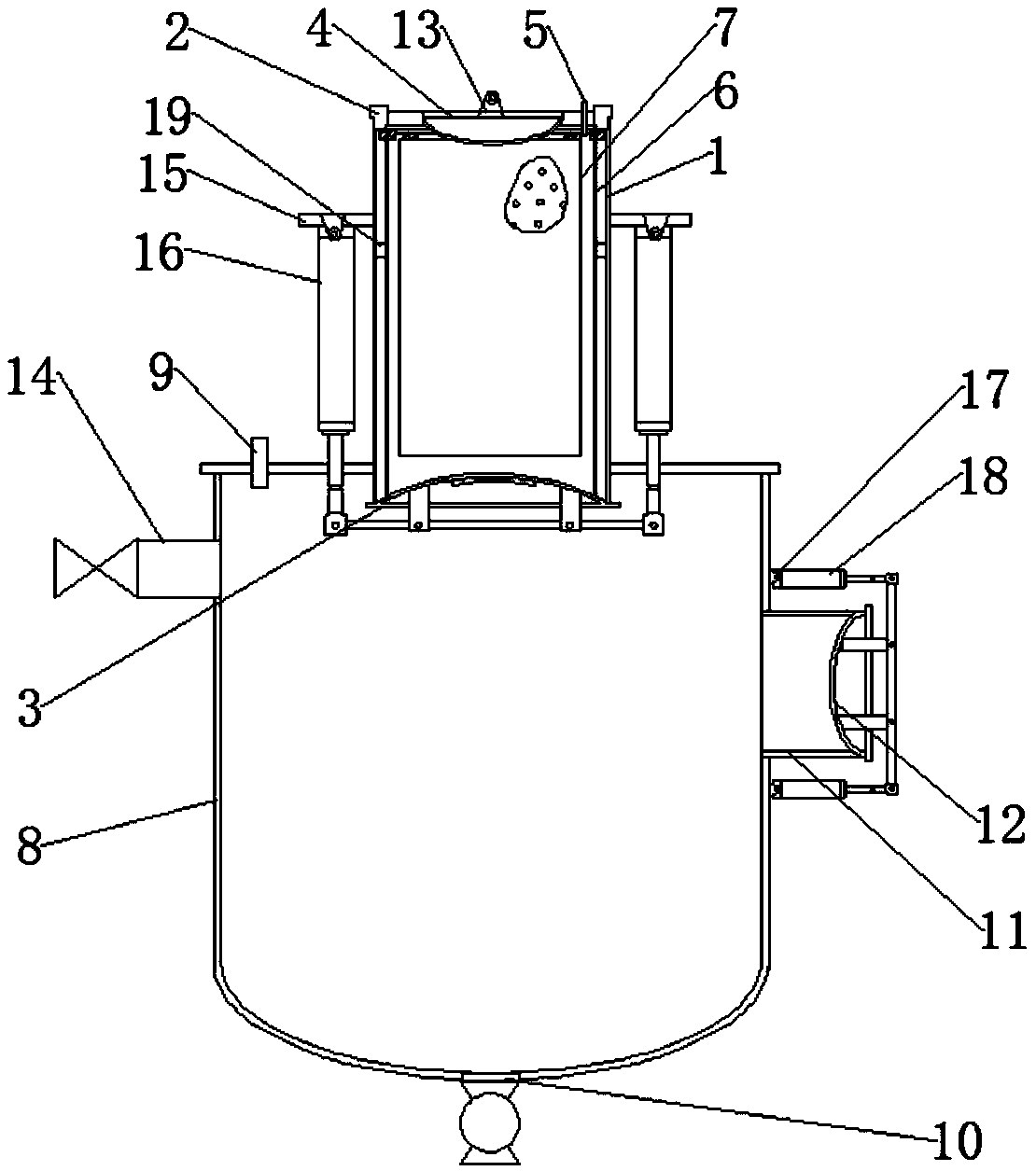

Embodiment 1

[0072] The method for co-producing collagen polypeptide and ultrafine bone powder based on the hard bone liquefaction equipment includes: selecting edible animal hard bone and crushing it to a particle size of 3 cm; putting the broken hard bone into the stainless steel In the cage, close the lower cover, seal the outer cavity, and feed saturated water vapor with a pressure of 1.5 MPa into the first steam inlet to perform primary liquefaction. The primary liquefaction time is 10 minutes, and at the same time Evacuate the pressure of the second liquefaction chamber to a negative pressure of -0.08MPa, then open the lower cover to perform the first pressure relief, and after the first pressure relief is completed, the second steam inlet Introduce saturated water vapor with a pressure of 1.0MPa for secondary liquefaction, the secondary liquefaction time is 5min, and finally perform a second pressure release to obtain liquid and solid phases; centrifuge the liquid phase at a speed of...

Embodiment 2

[0074] The method for co-producing collagen polypeptide and ultrafine bone powder based on the hard bone liquefaction equipment includes: selecting edible animal hard bone and crushing it to a particle size of 4 cm; putting the broken hard bone into the stainless steel In the cage, close the lower cover, seal the outer cavity, and feed saturated water vapor with a pressure of 1.8 MPa into the first steam inlet to perform primary liquefaction. The primary liquefaction time is 15 minutes, and at the same time Evacuate the pressure of the second liquefaction chamber to a negative pressure of -0.08MPa, then open the lower cover to perform the first pressure relief, and after the first pressure relief is completed, the second steam inlet Introduce saturated water vapor with a pressure of 1.5MPa for secondary liquefaction, the secondary liquefaction time is 8 minutes, and finally perform a second pressure release to obtain liquid and solid phases; centrifuge the liquid phase at a spe...

Embodiment 3

[0076] The method for co-producing collagen polypeptide and ultrafine bone powder based on the hard bone liquefaction equipment includes: selecting edible animal hard bone and crushing it to a particle size of 5 cm; putting the broken hard bone into the stainless steel In the cage, close the lower cover, seal the outer cavity, and introduce saturated water vapor with a pressure of 2.3 MPa into the first steam inlet to perform primary liquefaction. The primary liquefaction time is 20 minutes, and at the same time Evacuate the pressure of the second liquefaction chamber to a negative pressure of -0.09MPa, then open the lower cover to perform the first pressure relief, and after the first pressure relief is completed, the second steam inlet Introduce saturated water vapor with a pressure of 2.0MPa for secondary liquefaction, the secondary liquefaction time is 10 minutes, and finally perform a second pressure release to obtain liquid and solid phases; centrifuge the liquid phase at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com