Cylinder type separation test device for non-uniform bed load particles and test method of device

A test device and non-uniform technology, applied in the direction of particle and sedimentation analysis, measuring device, particle size analysis, etc., can solve the problems of complex physical process and poor effectiveness, and achieve the effect of reliable test basis, avoiding water velocity and simplifying physical model

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

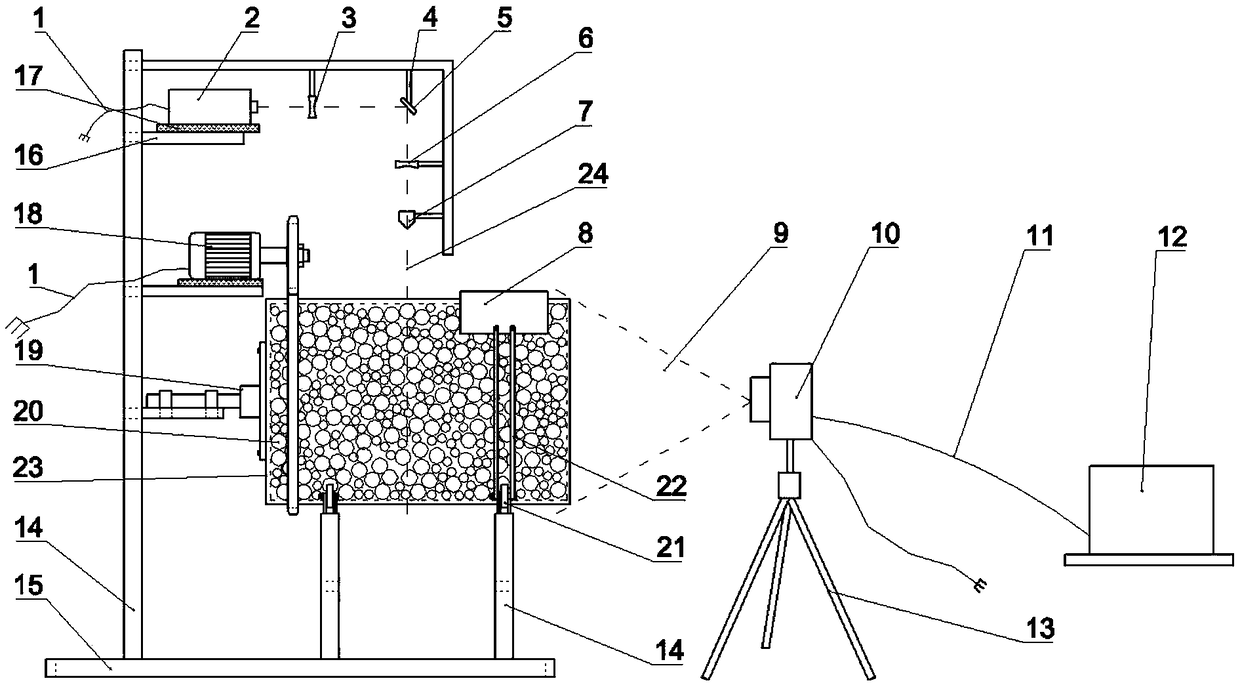

[0057] Example 1: Effect test of particle size ratio in the process of mass separation

[0058] The transparent cylinder 23 of prefabricated plexiglass material is 40cm in diameter, and length is 60cm, and the wall thickness of cylinder is 1.5cm. The black protective cover 8 of prefabricated organic plastic material, thickness is 3cm. Prepare some rectangular square tubes of aluminum alloy material, prepare some screws, the primary support 14 needs to be a rectangular square tube of 5cm*10cm, and the secondary support 16 needs to be a rectangular square tube of 5cm*5cm. The prefabricated protective cover 8 is fixed on the primary support 14 around the outer side of the transparent cylinder 23 through the arc-shaped fixing strip 22 . Purchasing maximum rotating speed is 5r / s, diameter is the driving motor 18 of 10cm, and is installed on the support 14, and its rotating shaft head installs gear 26, makes it mesh with transparent cylinder 23 outer gears 25. The black-and-white ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com