Ultrahigh-strength-toughness medium-manganese phase-change induced plasticity steel and preparation method thereof

A technology that induces plasticity and ultra-high strength, which is applied in the field of high-strength steel preparation, can solve the problems of long time consumption and low production efficiency, and achieve the effects of reducing production costs, high feasibility, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. According to the ingredients in Table 1, the alloy ingredients are carried out, and the intermediate frequency vacuum induction melting furnace is used for smelting. After refining and vacuum degassing, it is poured into columnar steel ingots under the protection of argon.

[0028] 2. The as-cast steel ingot is homogenized and annealed at 1200℃~1250℃ for 1.5h-2h and then forged. The starting forging temperature is 1200±5℃, the final forging temperature is 850±5℃, then cooled to room temperature, and the final shape is 100mm (width)×30mm (thickness) slab sample.

[0029] 3. Heat the forged slab at 1150°C-1200°C for 1.5h-2h, then start rolling at 1150±5°C, finish rolling at 880±5°C, the thickness of the hot-rolled plate is 4-6mm, and finally air-cool to room temperature.

[0030] Table 1 The preferred alloy composition 1 of medium manganese steel in the present invention

[0031]

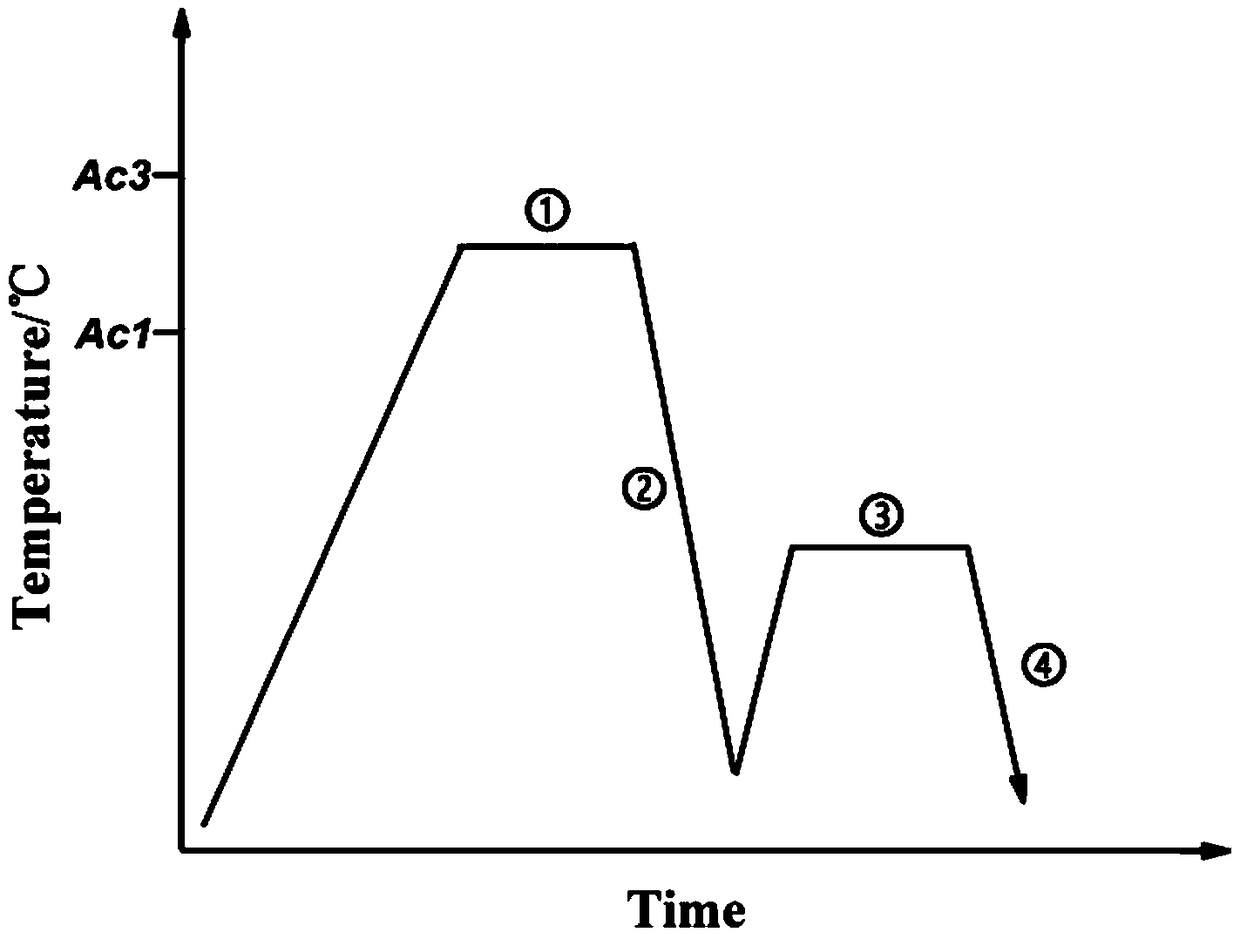

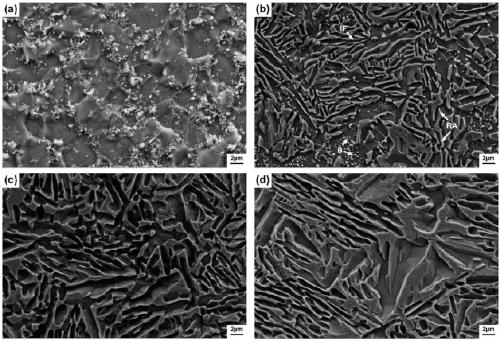

[0032] The hot-rolled material is subjected to heat treatment structure control, mai...

Embodiment 2

[0038] According to the composition of Table 4, the alloy ingredients are carried out, and the intermediate frequency vacuum induction melting furnace is used for smelting. After refining and vacuum degassing, it is poured into columnar steel ingots under the protection of argon.

[0039] 2. The as-cast steel ingot is homogenized and annealed at 1200℃~1250℃ for 1.5h-2h and then forged. The starting forging temperature is 1200±5℃, the final forging temperature is 850±5℃, then cooled to room temperature, and the final shape is 100mm (width)×30mm (thickness) slab sample.

[0040] 3. Heat the forged slab at 1150°C-1200°C for 1.5h-2h, then start rolling at 1150±5°C, finish rolling at 880±5°C, the thickness of the hot-rolled plate is 4-6mm, and air-cool to room temperature.

[0041] 4. Heat the hot-rolled sample at 770-800°C for 1 hour, then quench it, and then temper it at 200°C for 20 minutes. Pickle the tempered sample in 1:3 hydrochloric acid solution for 20 minutes to remove th...

Embodiment 3

[0048] 1. According to the ingredients in Table 6, the alloy ingredients are carried out, and the intermediate frequency vacuum induction melting furnace is used for smelting. After refining and vacuum degassing, it is poured into columnar steel ingots under the protection of argon.

[0049] 2. The as-cast steel ingot is homogenized and annealed at 1200℃~1250℃ for 1.5h-2h and then forged. The starting forging temperature is 1200±5℃, the final forging temperature is 850±5℃, then cooled to room temperature, and the final shape is 100mm (width)×30mm (thickness) slab sample.

[0050] 3. Heat the forged slab at 1150°C-1200°C for 1.5h-2h, then start rolling at 1150±5°C, finish rolling at 880±5°C, the thickness of the hot-rolled plate is 4-6mm, and finally air-cool to room temperature.

[0051] Table 6 Preferred alloy composition 3 of medium manganese steel in the present invention

[0052]

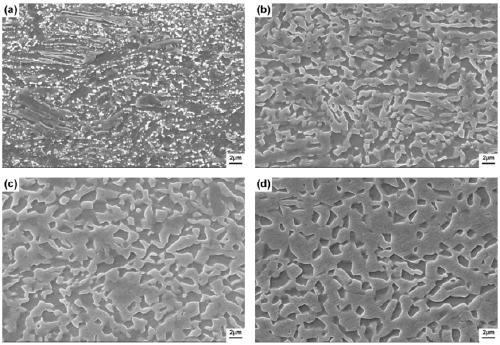

[0053] The hot-rolled material is subjected to heat treatment structure control, mainly ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com