High dielectric ceramic/PVDF composite material and preparation method thereof

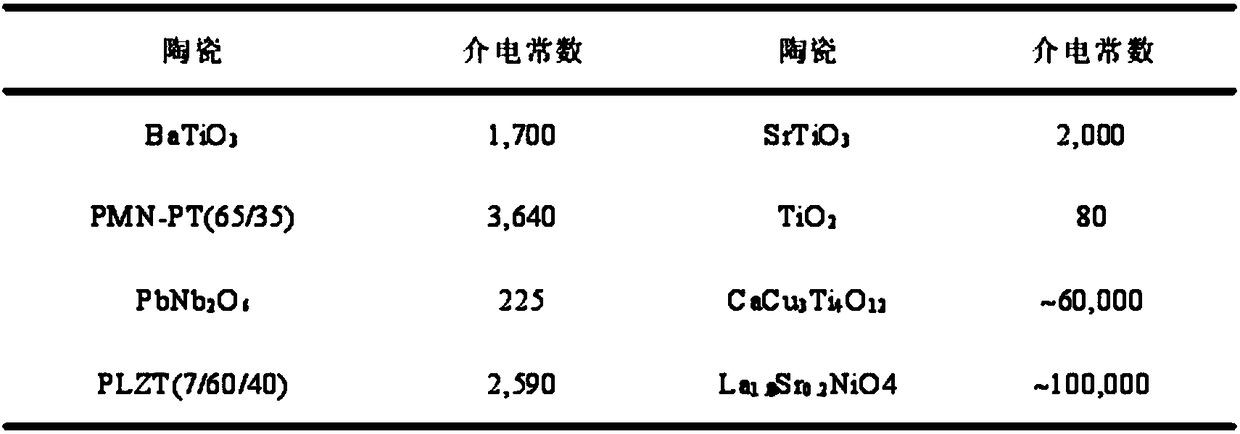

A composite material and high dielectric technology, applied in the field of high dielectric ceramic/PVDF composite materials and preparation, can solve the problems of energy storage density limitation and low dielectric strength, and achieve high dielectric constant, low dielectric and low loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

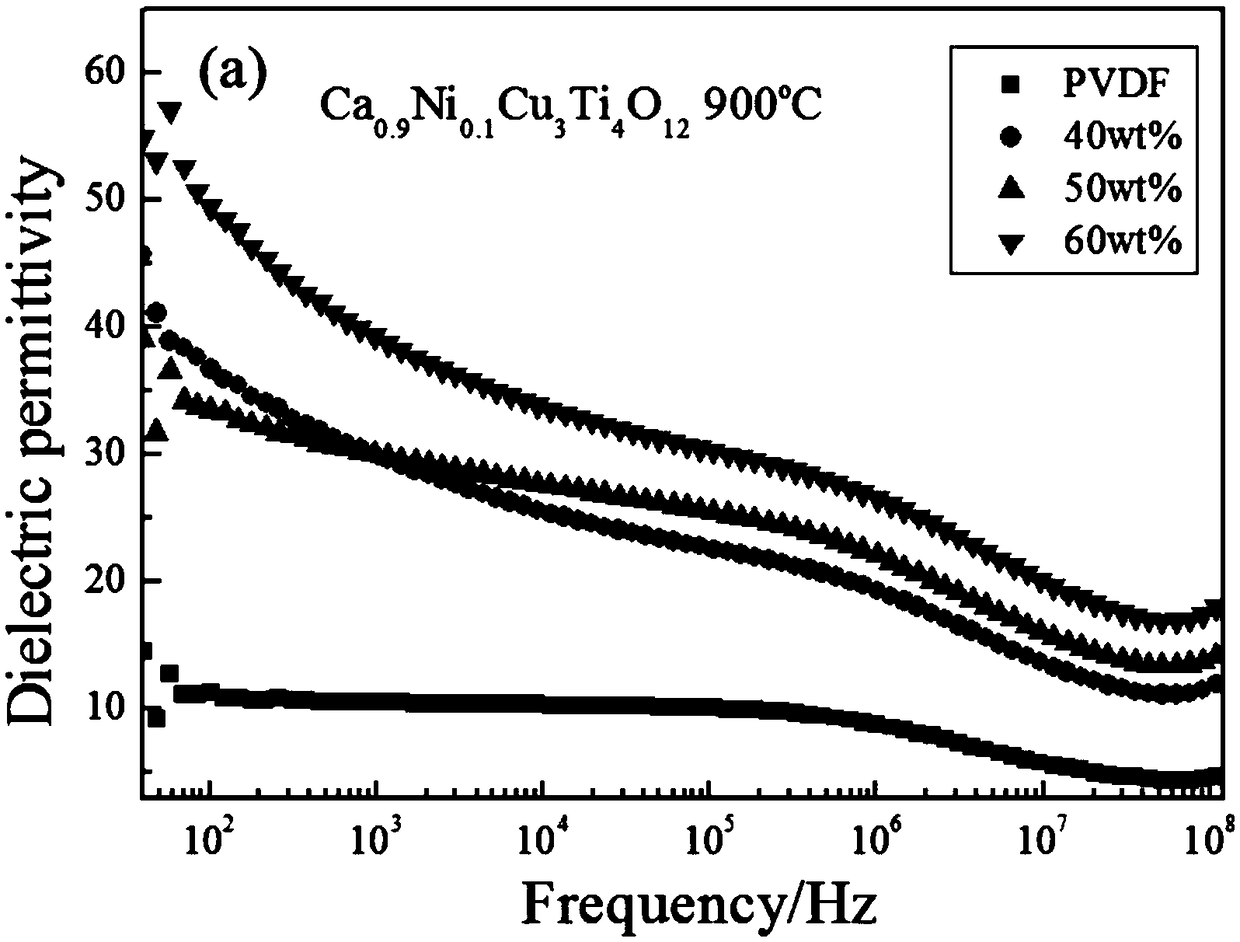

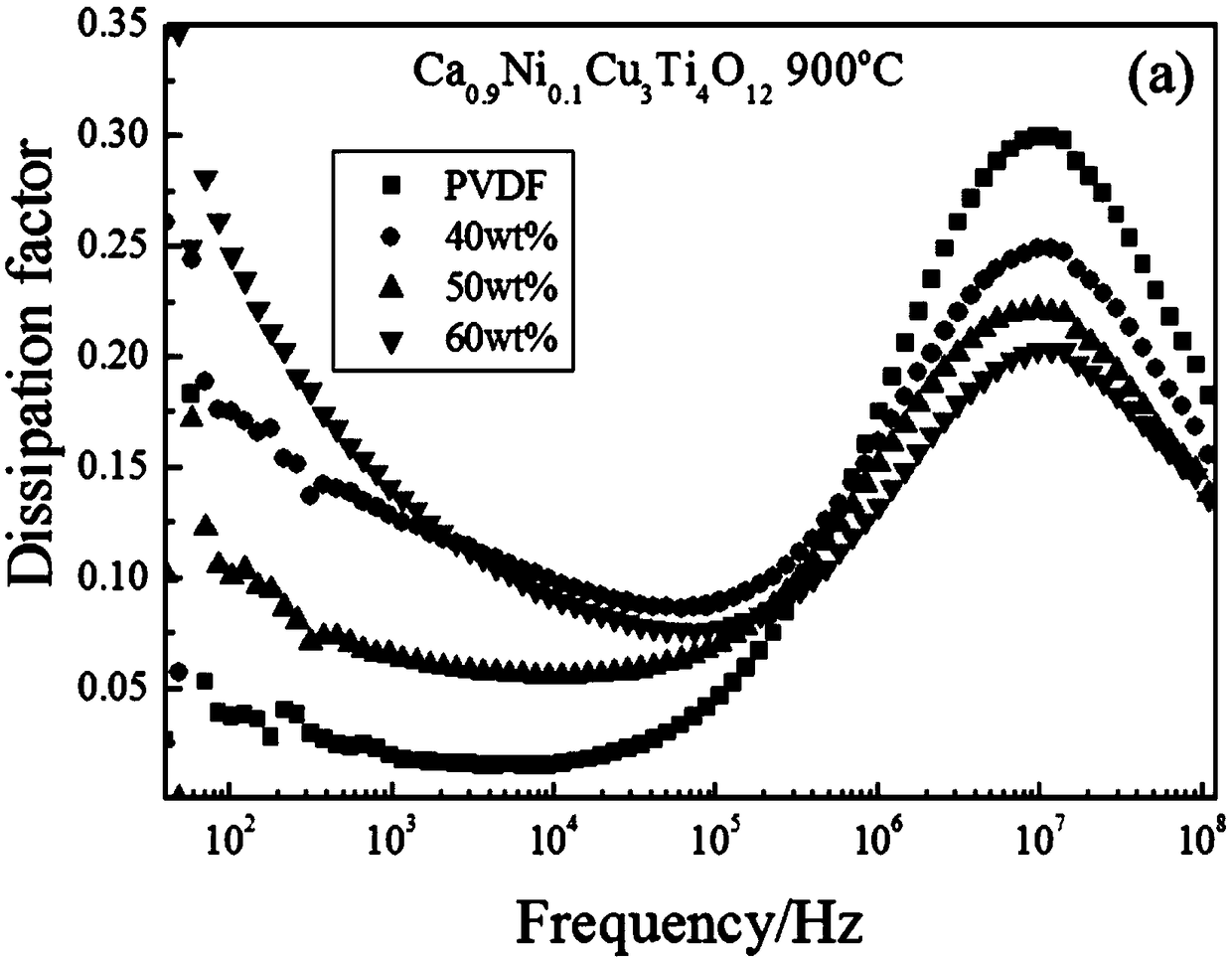

[0033] Ca 0.9 Ni 0.1 Cu 3 Ti 4 o 12 The preparation process of / PVDF composite material is as follows:

[0034] 1) Preparation of ceramic powder Ca 0.9 Ni 0.1 Cu 3 Ti 4 o 12

[0035] 1.1) Add 0.9mol of Ca(NO 3 ) 2 , 0.1mol of Ni(NO 3 ) 2 .6H 2 O and Cu(N0 3 )2·3H 2 O These three substances were dissolved in ethanol and deionized water volume ratio (3:1) solution.

[0036] 1.2) Ti(OC 4 h 9 ) 4 Dissolved to form a 0.5mol / L solution.

[0037] 1.3) Mix the above two solutions, add an appropriate amount of nitric acid to the mixed solution, stir for 20 minutes, and then react at 50 degrees for 24 hours.

[0038] 1.4) Dry the formed gel at 80 degrees to form a xerogel.

[0039] 1.5) Dry the formed xerogel at 900°C for two hours to obtain ceramic powder Ca 0.9 Ni 0.1 Cu 3 Ti 4 o 12 .

[0040]2) Mixing of ceramics and PVDF

[0041] 2.1) Dissolve 1.5g of PVDF in DMF to obtain a PVDF solution.

[0042] 2.2) Add 1 g of the prepared ceramic powder into the PV...

Embodiment 2

[0046] Ca 0.8 Ni 0.2 Cu 3 Ti 4 o 12 The preparation process of / PVDF composite material is as follows:

[0047] 1) Preparation of ceramic powder Ca 1-x Ni x Cu 3 Ti 4 o 12

[0048] 1.1) 0.8molCa(NO 3 ) 2 ,, 0.2molNi(NO 3 ) 2 .6H 2 O, Cu(N0 3 )2·3H 2 O These three substances were dissolved in ethanol and deionized water volume ratio (3:1) solution.

[0049] 1.2) Ti(OC 4 h 9 ) 4 Dissolved to form a 0.5mol / L solution.

[0050] 1.3) Mix the above two solutions, add an appropriate amount of nitric acid to the mixed solution, stir for 20 minutes, and then react at 50 degrees for 24 hours.

[0051] 1.4) Dry the formed gel at 80 degrees to form a xerogel.

[0052] 1.5) Dry the formed xerogel at 850°C for two hours to obtain ceramic powder Ca 0.8 Ni 0.2 Cu 3 Ti 4 o 12 .

[0053] 2) Mixing of ceramics and PVDF

[0054] 2.1) 1.5g of PVDF was dissolved in DMF to obtain a PVDF solution.

[0055] 2.2) Add 1.5 g of the prepared ceramic powder into the PVDF solut...

Embodiment 3

[0059] Ca 0.5 Ni 0.5 Cu 3 Ti 4 o 12 The preparation process of / PVDF composite material is as follows:

[0060] 1) Preparation of ceramic powder Ca 1-x Ni x Cu 3 Ti 4 o 12

[0061] 1.1) 0.5molCa(NO 3 ) 2 ,, 0.5molNi(NO 3 ) 2 .6H 2 O, Cu(N0 3 )2·3H 2 O These three substances were dissolved in ethanol and deionized water volume ratio (3:1) solution.

[0062] 1.2) Ti(OC 4 h 9 ) 4 Dissolved to form a 0.5mol / L solution.

[0063] 1.3) Mix the above two solutions, add an appropriate amount of nitric acid to the mixed solution, stir for 20 minutes, and then react at 50 degrees for 24 hours.

[0064] 1.4) The formed gel was dried at 80° C. to form a xerogel.

[0065] 1.5) Dry the formed xerogel at 1000°C for two hours to obtain ceramic powder Ca 0.5 Ni 0.5 Cu 3 Ti 4 o 12 .

[0066] 2) Mixing of ceramics and PVDF

[0067] 2.1) 1 g of PVDF was dissolved in DMF to obtain a PVDF solution.

[0068] 2.2) Add 1.5 g of the prepared ceramic powder into the PVDF sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com