Preparation method of polysiloxane fluid containing active hydrogen at single end

A polysiloxane and active hydrogen technology, applied in the field of polysiloxane fluid preparation, can solve the problems of many by-products, high content, and difficult separation of by-products, and achieve mild reaction conditions, few by-products, and high content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

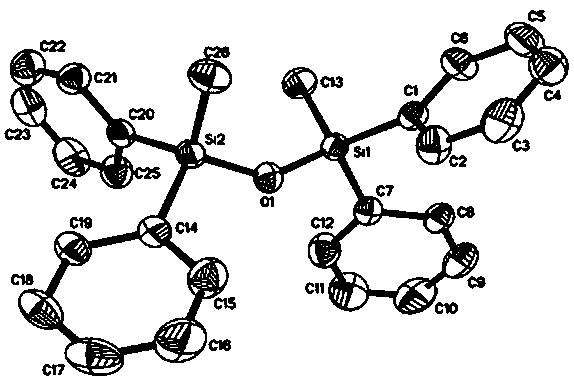

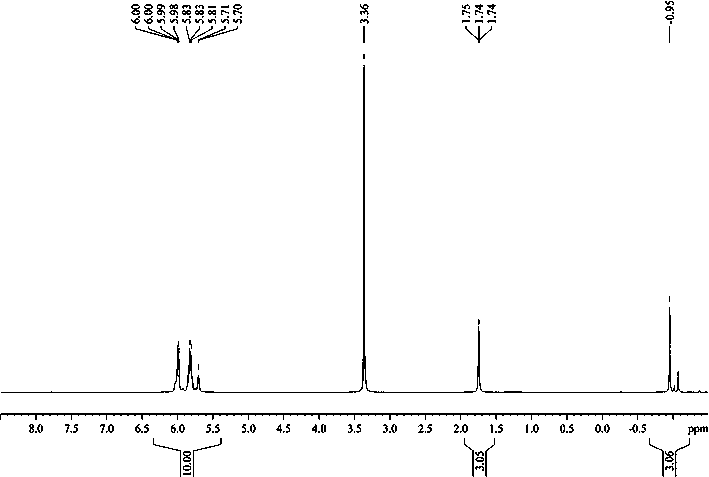

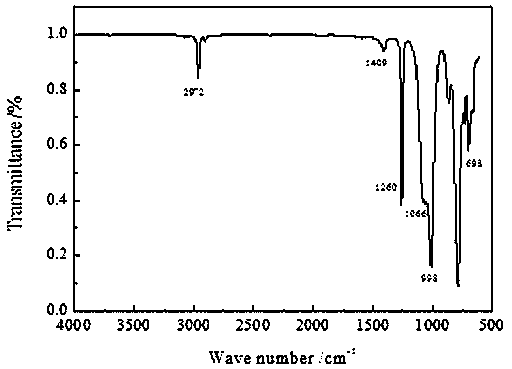

Image

Examples

Embodiment 1

[0041] (1) Preparation of 1,3-dimethyl-1,1,3,3-tetraphenyldisiloxane: in a 500mL three-necked flask with Pt-100 platinum resistance, mechanical stirring and Teflon stirring paddle In, add 120g (0.496mol) methyldiphenylethoxysilane, 145mL concentration is the LiOH aqueous solution of 5wt%; After the material in the bottle rises from room temperature to 100 ℃ with the speed of 1.25 ℃ / min, under this temperature After reacting for 11 hours, collect the ethanol-water mixed solution produced by the hydrolysis reaction; in order to avoid the increase of LiOH concentration after water evaporation, an appropriate amount of deionized water should be added during the reaction. In the later stage of the reaction, measure the instantaneous refractive index of the distillate at any time, when the refractive index (n D 20 ) when the value was close to 1.3330, the reaction was stopped, and the mixture remaining in the three-necked flask was cooled to room temperature to obtain a white solid...

Embodiment 2

[0055] 50g (0.169mol) D 4Put it into a 100mL three-necked flask, add siloxane quality 1wt% concentrated sulfuric acid as a polymerization catalyst, raise the temperature to 80°C, react for 1h, and then cool to room temperature; 10g (0.042mol) of methyl diphenyl Sodium silanolate is added to concentrated sulfuric acid catalyzed D 4 In the ring-opening polymerization product, the temperature was raised to maintain the reaction temperature at 45°C, and the reaction was carried out under stirring for 5 hours. After cooling to room temperature, it was filtered to obtain 44.5 g of methyldiphenylsiloxy-terminated polysiloxane sodium salt solution, with a yield of 74.2%.

[0056] According to the molar ratio of methyldiphenylsiloxy-terminated polysiloxane sodium salt: dimethylchlorosilane = 1: 1.05, at 20°C, weigh 4.1g (0.043mol) dimethylchlorosilane (Me 2 HSiCl) was added into a 100mL three-necked flask, cooled to 10°C, and 44.5g of methyldiphenylsiloxy-terminated polysiloxane sodiu...

Embodiment 3

[0062] 100g (0.337mol) D 4 Put it into a 250mL three-necked flask, add concentrated sulfuric acid with a siloxane quality of 3.0wt% as a polymerization catalyst, heat up to 65°C, react for 4h, and then cool to room temperature; 12.5g (0.0578mol) of methyl Sodium diphenylsilanolate is added to concentrated sulfuric acid catalyzed D 4 In the ring-opening polymerization product, the temperature was raised to maintain the reaction temperature at 50° C., and the reaction was carried out under stirring for 10 h. After cooling to room temperature, it was filtered to obtain 90.5 g of methyldiphenylsiloxy-terminated polysiloxane sodium salt solution with a yield of 80%.

[0063] According to the molar ratio of methyldiphenylsiloxy-terminated polysiloxane sodium salt: dimethylchlorosilane = 1: 1.05, weigh 5.2g (0.055mol) dimethylchlorosilane (Me 2 HSiCl) was added into a 250mL three-necked flask, cooled to 5°C, and under stirring, 90.5g of methyldiphenylsiloxy-terminated polysiloxane s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com