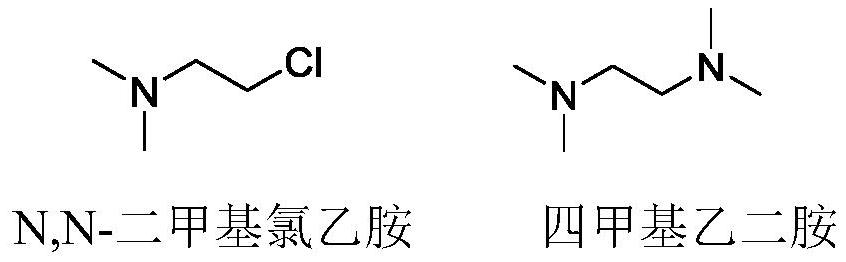

Self-binding acid integrated production method of n,n-dimethylchloroethylamine and tetramethylethylenediamine

A technology of tetramethylethylenediamine and dimethylchloroethylamine, which is applied in the field of co-production of important intermediates N,N-dimethylchloroethylamine and tetramethylethylenediamine, which can solve industrial production problems The limited significance of benzene, the high toxicity of benzene as a solvent, etc., achieve the effect of safe reaction, simple post-processing operation, simple and clean process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

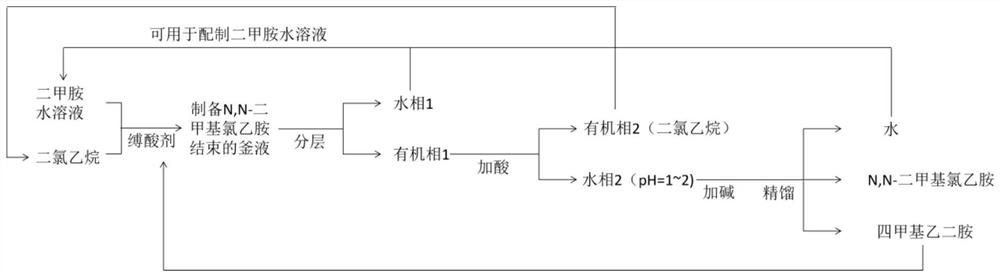

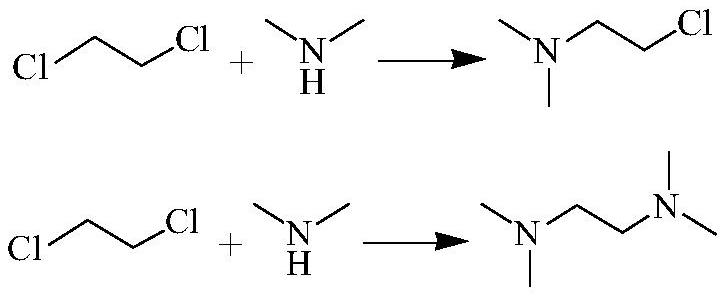

[0047] Embodiment 1, a kind of technique of producing N,N-dimethylchloroethylamine and co-production of tetramethylethylenediamine. Taking dichloroethane and 33% dimethylamine aqueous solution as starting materials, the following steps are carried out successively:

[0048] (1) Synthesis:

[0049] Add 67.5g dimethylamine aqueous solution (0.5mol, mass concentration is 33%), 148.5g dichloroethane (1.5mol) and 58g acid-binding agent tetramethylethylenediamine (0.5mol) in 500ml autoclave, will After replacing the reactor with nitrogen for 3 times, fill it with nitrogen to 1.5MPa, start stirring, raise the temperature to 35°C for reaction, and the reaction time is 5h, and the resulting reaction solution is collected.

[0050] (2) Separation:

[0051] The reaction solution in step (1) was allowed to stand, separated into layers, and the water layer was set aside (the water layer was composed of water, tetramethylethylenediamine hydrochloride and other components), and the organic...

Embodiment 2-6

[0068] Embodiment 2-6, change the reaction pressure in embodiment 1 into 3MPa, all the other are equal to embodiment 1;

[0069] The yield of N,N-dimethylchloroethylamine in step (2) is 23.2%, and the yield of tetramethylethylenediamine is 75%.

[0070] In step (4), the yield of N,N-dimethylchloroethylamine was 23.0%, and the yield of tetramethylethylenediamine was 75.1%.

Embodiment 2-7

[0071] Embodiment 2-7, change the mol ratio of dimethylamine and dichloroethane in embodiment 1 into 1:1, all the other are equal to embodiment 1;

[0072] The yield of N,N-dimethylchloroethylamine in step (2) is 18%, and the yield of tetramethylethylenediamine is 80.8%.

[0073] The yield of N,N-dimethylchloroethylamine in step (4) was 17.6%, and the yield of tetramethylethylenediamine was 80.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com