A kind of cyanide-free electroplating brass plating solution containing ionic liquid additive and its application method

A technology of ionic liquids and additives, applied in the field of improving the performance of deposited coatings, can solve problems such as poor continuity of coatings, unstable copper-zinc ratio, missing plating, etc., and achieve high energy consumption, difficult maintenance and management, simple and clean process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

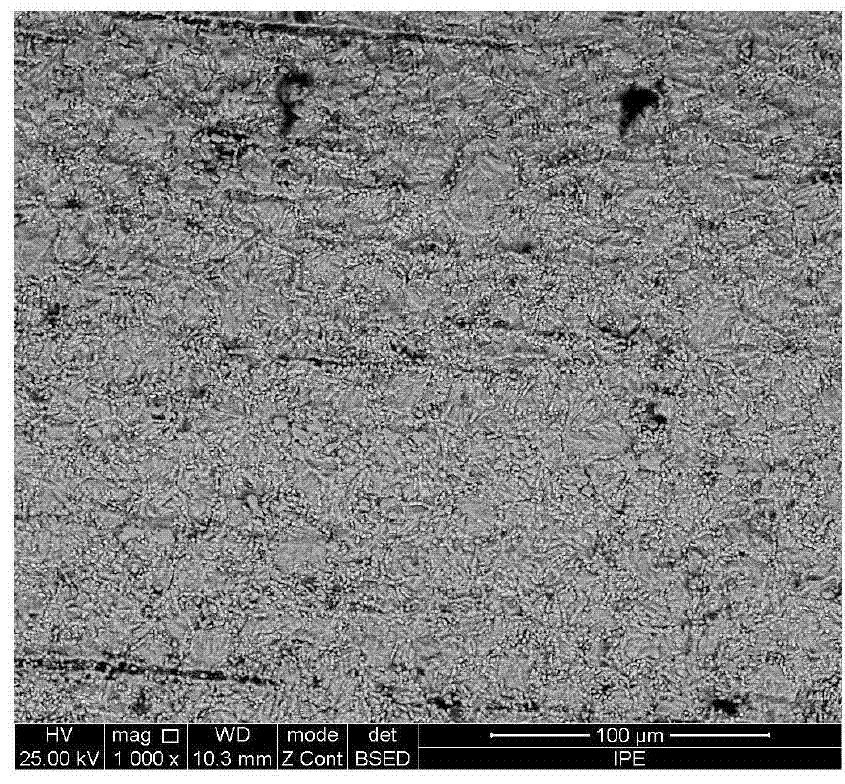

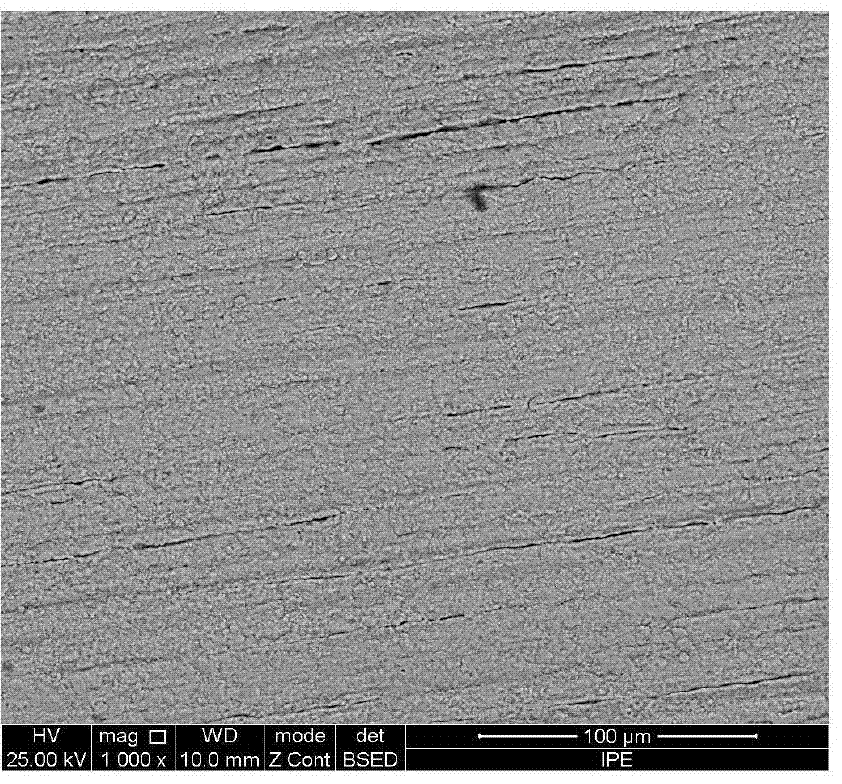

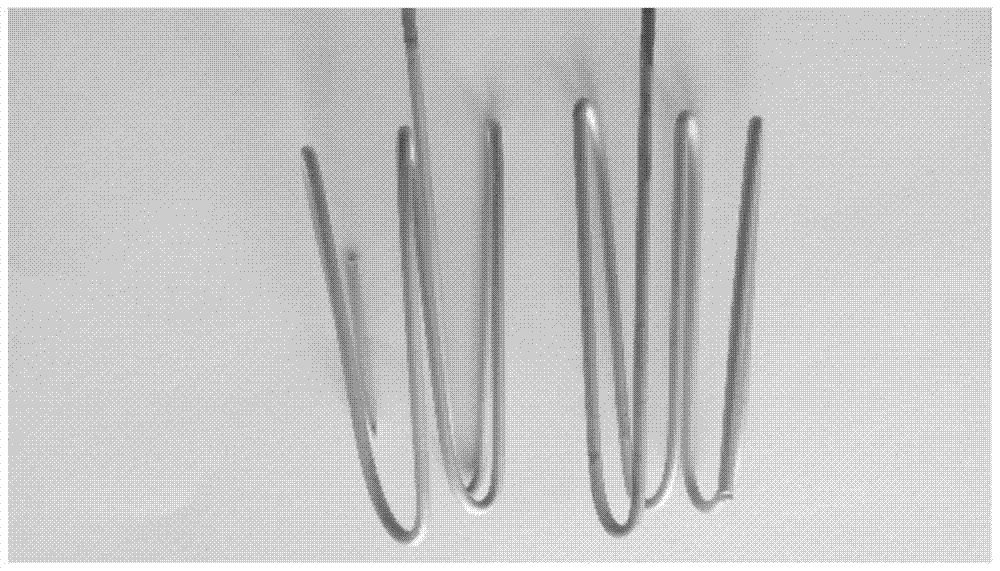

[0034] The ionic liquid [OMIM]HSO 4 Dry in vacuum at 50°C for 24 hours, in the glove box, under the protection of inert gas argon, measure [OMIM]HSO with a pipette 4 And added to the pre-prepared plating solution, in the plating solution [OMIM]HSO 4 Concentration is 5.0mg / L, keep stirring until the plating solution is fully mixed and even. The steel cord base material is degreased with acetone, washed with ethanol, washed with water, derusted with pickling, washed with water and activated as the cathode; the anode is made of brass plate (H68), polished with sandpaper, degreased with acetone, washed with water, After ethanol washing, water washing, acid washing and water washing pretreatment, it is ready for use. Add the plating solution into the plating tank, the distance between the anode and the cathode is about 4.0cm, the deposition temperature is room temperature (25±3°C), and the current density is 1.75A / dm 2 , the electrodeposition process uses a peristaltic pump to c...

example 2

[0036] The difference between this embodiment and embodiment 1 is that the ionic liquid additive added in the cyanide-free plating solution is [HMIM] HSO 4 , the concentration is 20mg / L, the plating time is 5min, and the current density is 1.5A / dm 2 , the others are the same as in Example 1. On the steel cord base material, a uniform, continuous and dense brass coating is prepared on the steel cord substrate, and its copper-zinc ratio and thickness etc. 2009 "Steel cord for rubber track" and the technical requirements of relevant national standards.

example 3

[0038] The difference between this embodiment and embodiment 2 is that the ionic liquid additive added in the cyanide-free plating solution is [BMIM] HSO 4 , the concentration is 10mg / L, the plating time is 10min, and the current density is 1.5A / dm 2, the others are the same as in Example 2. On the steel cord base material, a uniform, continuous and dense brass coating is prepared on the steel cord base material. 2009 "Steel cord for rubber track" and the technical requirements of relevant national standards.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com