A three-dimensional porous nano-network structure MOS immobilized by ultra-small particles 2 Composite powder and its preparation method and application

A three-dimensional porous, network structure technology, applied in nanotechnology, structural parts, nanotechnology and other directions, can solve the problems of reducing electrochemical performance, affecting electronic/ionic conductivity, etc., to improve electrochemical performance, uniform morphology, The effect of uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

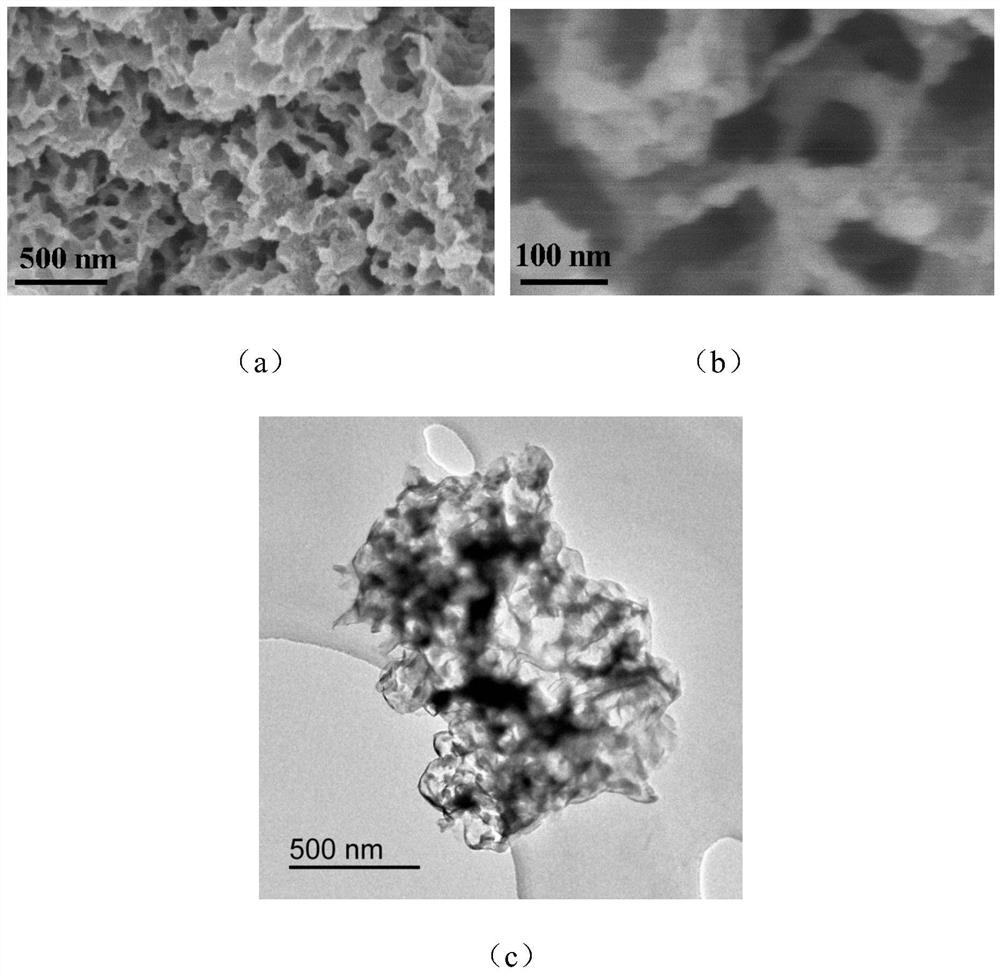

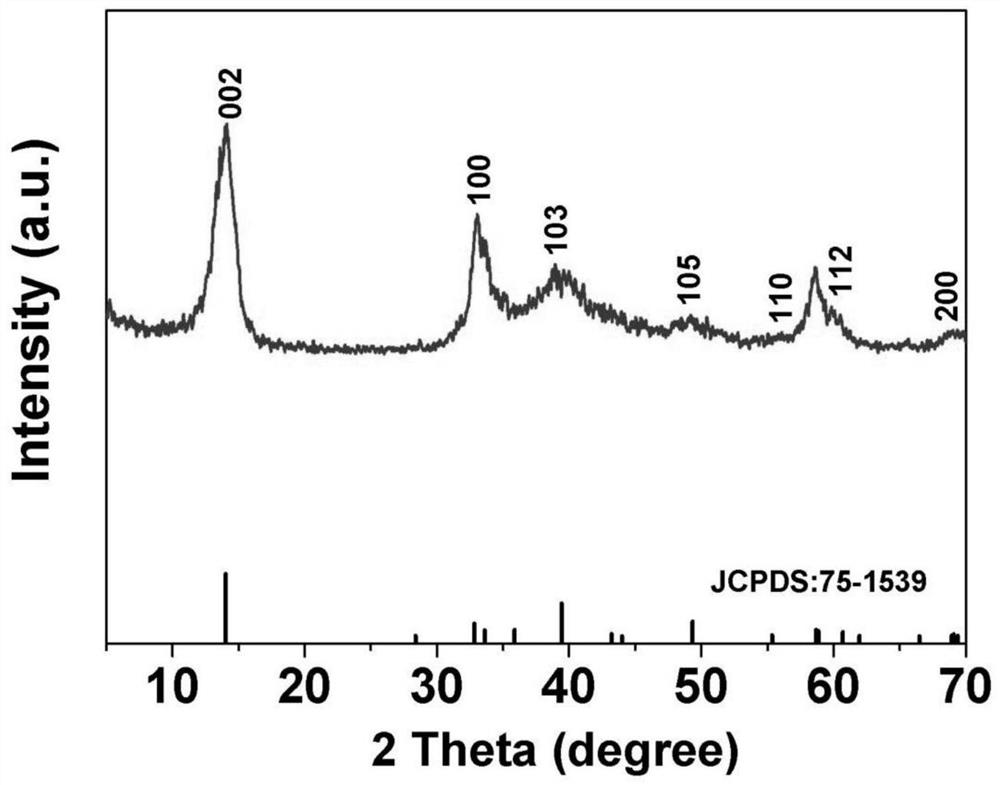

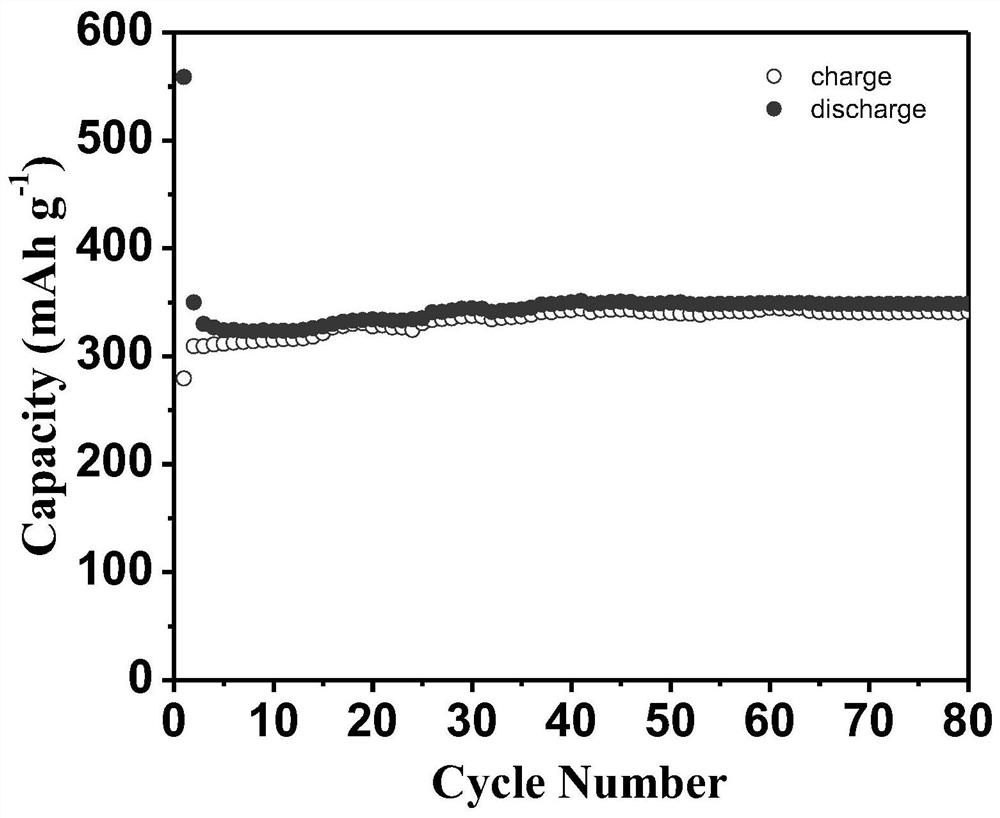

[0040] A three-dimensional porous nano-network structure MoS immobilized by ultra-small particles 2 The preparation method of composite powder comprises the following steps:

[0041] 1) put H 2 o 2 Make 100ml solution A with NMP solution at a volume ratio of 1:0.5;

[0042] 2) Disperse 80mg of pure molybdenum disulfide nanosheets into 100ml of solution A, and stir at 35°C for 8h to obtain mixture B;

[0043] 3) The mixture B was centrifuged at 5000rpm for 50 minutes, and the supernatant was collected as solution C, that is, the mixture evenly dispersed in H 2 o 2 and ultra-small MoS in mixed solution of NMP 2 ;

[0044] 4) Dissolve 1.5 g of thiourea in 100 ml of deionized water to obtain solution D. Add 0.5 g MoO with stirring 3 into solution D, MoO 3 Distribute evenly in it; finally, slowly add 2ml of solution C to it, and finally obtain precursor E by heating while stirring;

[0045] 5) Put the precursor E in a magnetic boat and put it into a horizontal tube furnac...

Embodiment 2

[0049] A three-dimensional porous nano-network structure MoS immobilized by ultra-small particles 2 The preparation method of composite powder comprises the following steps:

[0050] 1) put H 2 o 2 Make 100ml solution A with NMP solution at a volume ratio of 1:0.8;

[0051] 2) Disperse 90mg of pure molybdenum disulfide nanosheets into 100ml of solution A, and stir at 40°C for 9h to obtain mixture B;

[0052] 3) The mixture B was centrifuged at 6000rpm for 45 minutes, and the supernatant was collected as solution C, that is, the solution evenly dispersed in H 2 o 2 and ultra-small MoS in mixed solution of NMP 2 ;

[0053] 4) Dissolve 1.8g of thiourea in 100ml of deionized water to obtain solution D; add 0.75g of MoO under stirring 3 into solution D, MoO 3 Evenly distributed in it; finally, slowly add 3ml of solution C to it, and finally obtain precursor E by heating while stirring;

[0054] 5) Put the precursor E in a magnetic boat and put it into a horizontal tube fur...

Embodiment 3

[0058] A three-dimensional porous nano-network structure MoS immobilized by ultra-small particles 2 The preparation method of composite powder comprises the following steps:

[0059] 1) put H 2 o 2 Make 100ml solution A with NMP solution at a volume ratio of 1:1.2;

[0060] 2) Disperse 100mg of pure molybdenum disulfide nanosheets into 100ml of solution A, and stir at 45°C for 10h to obtain mixture B;

[0061] 3) The mixture B was centrifuged at 6000rpm for 40 minutes, and the supernatant was collected as solution C, that is, the mixture evenly dispersed in H 2 o 2 and ultra-small MoS in mixed solution of NMP 2 ;

[0062] 4) Dissolve 2.0 g of thiourea in 100 ml of deionized water to obtain solution D; add 1.0 g of MoO under stirring 3 into solution D, MoO 3 Evenly distributed in it; finally, slowly add 4ml of solution C to it, and finally obtain precursor E by heating while stirring;

[0063] 5) Put the precursor E in a magnetic boat and put it into a horizontal tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com