A preparation method oflithium ion battery aluminum-plastic composite film with double heat conduction layers

An aluminum-plastic composite film, lithium-ion battery technology, applied in battery pack parts, battery box/jacket, battery box/cover material, etc., can solve problems such as explosion and material stability degradation, and achieve easy operation, high flexibility The effect of convenient industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

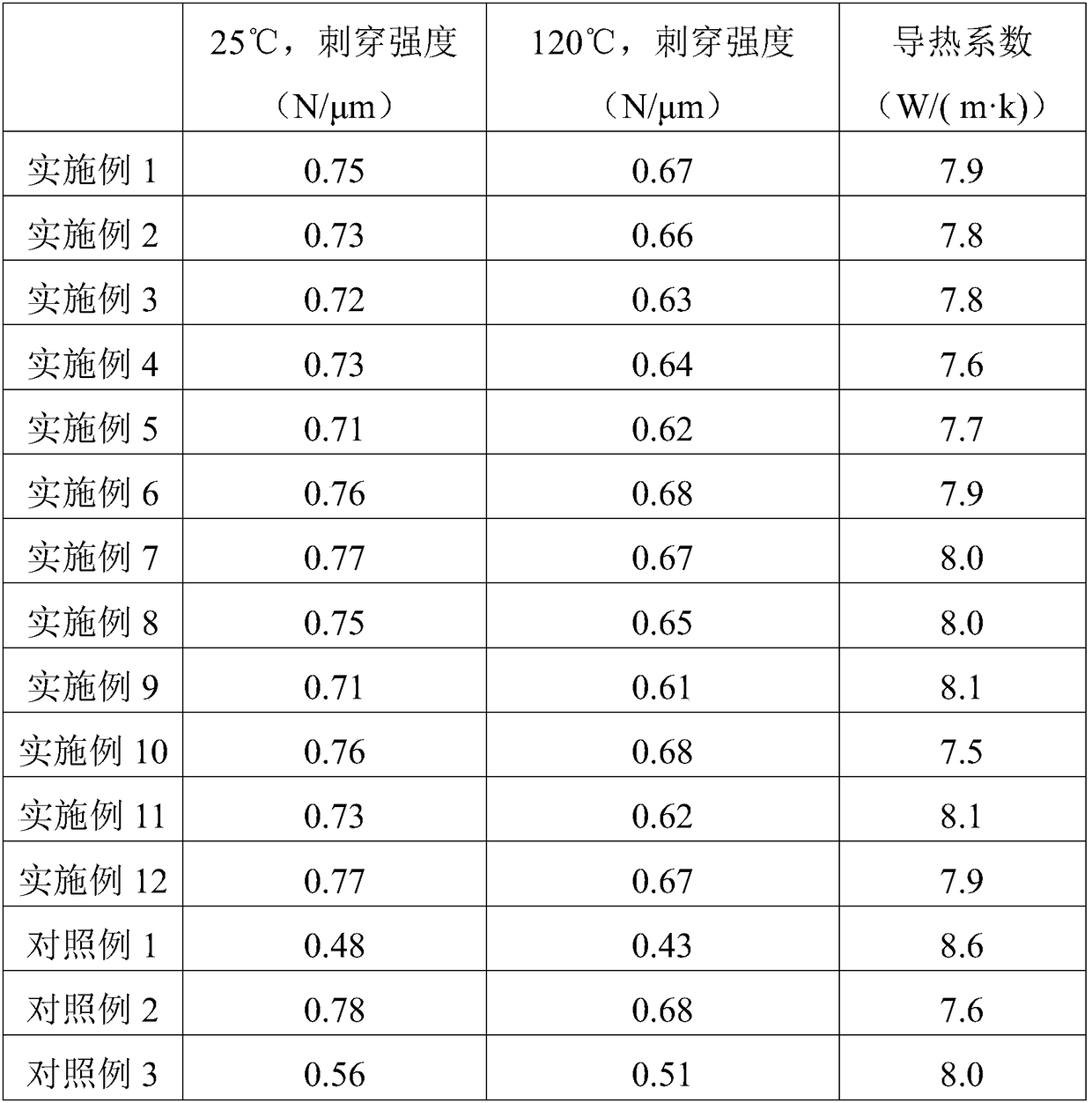

Examples

preparation example Construction

[0016] The invention provides a method for preparing an aluminum-plastic composite film for a lithium-ion battery with double heat-conducting layers, comprising the following steps:

[0017] (1) Apply a layer of low-temperature hot-melt adhesive evenly on one side of the aluminum foil, and then let it stand for 1-3 minutes, then cover the nylon scratch-resistant layer on the low-temperature hot-melt adhesive, and cold press them together at room temperature;

[0018] (2) Add powdered mineral fiber, graphene oxide and alumina powder to the solvent, add thermosetting resin glue and thermosetting resin curing agent during stirring, and ultrasonically disperse the mixture; coat the other side of the aluminum foil And form a hard heat-conducting layer. After the coating is completed, it is dried through a hot drying tunnel with a temperature of 60-80°C. During the drying tunnel, the aluminum foil is in a tight state;

[0019] (3) Add the flexible unsaturated polyester resin into th...

Embodiment 1

[0038]An aluminum-plastic composite film for lithium-ion batteries with double heat-conducting layers, comprising a nylon scratch-resistant layer, an aluminum foil layer, a hard heat-conducting layer and a flexible heat-conducting layer arranged sequentially from the outside to the inside, the nylon scratch-resistant layer and the aluminum foil Layers are bonded together by low-temperature hot-melt adhesive;

[0039] The hard heat conducting layer is prepared from the following raw materials in parts by weight: 35 parts of sepiolite fiber, 5 parts of graphene oxide, 4 parts of alumina powder, 28 parts of epoxy resin glue, and 5 parts of epoxy resin curing agent , 72 parts of ethyl acetate;

[0040] The flexible heat-conducting layer is prepared from the following raw materials in parts by weight: 55 parts of flexible unsaturated polyester resin, 2 parts of aliphatic blocked polyisocyanate curing agent, and 80 parts of ethyl acetate;

[0041] The nylon scratch-resistant layer ...

Embodiment 2

[0049] An aluminum-plastic composite film for lithium-ion batteries with double heat-conducting layers, comprising a nylon scratch-resistant layer, an aluminum foil layer, a hard heat-conducting layer and a flexible heat-conducting layer arranged sequentially from the outside to the inside, the nylon scratch-resistant layer and the aluminum foil Layers are bonded together by low-temperature hot-melt adhesive;

[0050] The hard heat conducting layer is prepared from the following raw materials in parts by weight: 30 parts of sepiolite fiber, 4 parts of graphene oxide, 4 parts of alumina powder, 24 parts of epoxy resin glue, and 4 parts of epoxy resin curing agent , 66 parts of ethyl acetate;

[0051] The flexible heat-conducting layer is prepared from the following raw materials in parts by weight: 48 parts of flexible unsaturated polyester resin, 1 part of aliphatic blocked polyisocyanate curing agent, and 75 parts of ethyl acetate;

[0052] The nylon scratch-resistant layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com