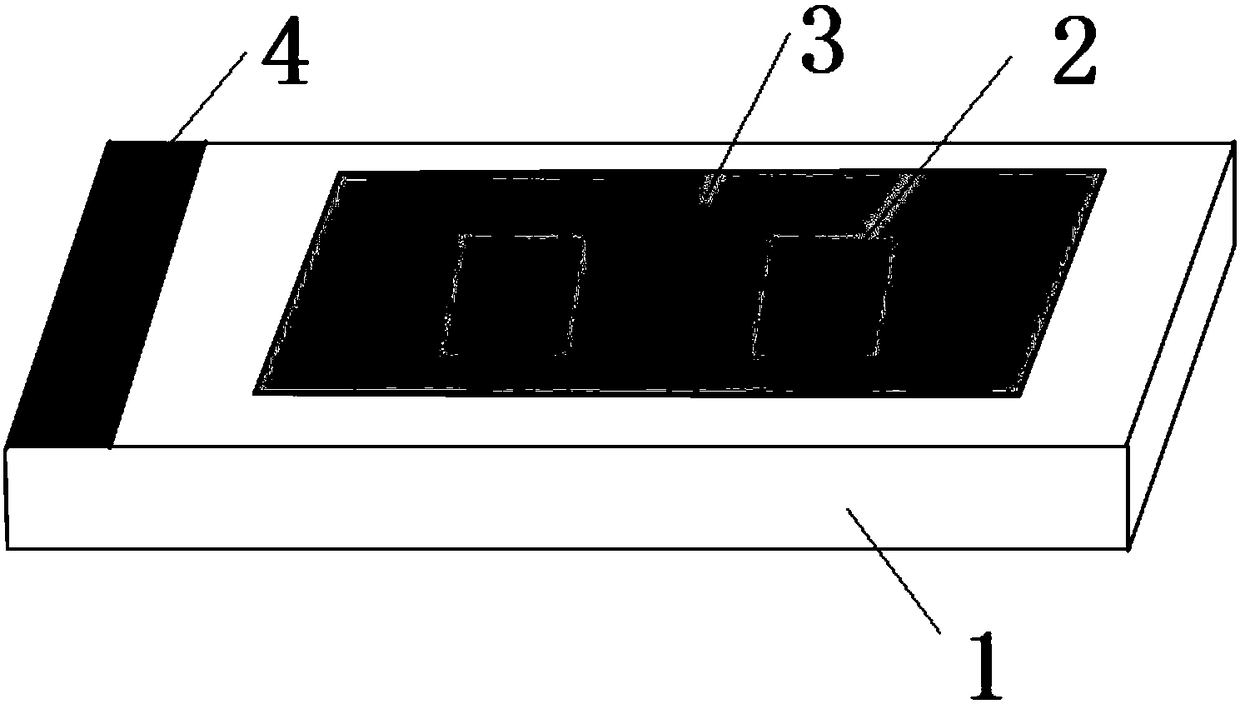

Porous silicon-based tungsten oxide film composite material gas sensitive sensor and preparation method and application thereof

A thin-film composite material and gas sensor technology, which is applied in the field of gas sensors, can solve the problems of gas response/recovery performance, poor selectivity and stability of porous silicon gas sensors, and the inability of porous silicon to have high gas sensitivity and limitations. The effect of good response/recovery performance, good selectivity and repeatability, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The technical solutions of the present invention will be further described below in conjunction with specific embodiments. It should be noted that: the following examples are illustrative, not limiting, and cannot limit the protection scope of the present invention with the following examples.

[0047] The raw materials used in the present invention are commercially available chemically pure reagents. The silicon wafer is a Prime-grade 4-inch single-sided polished p-type silicon wafer provided by Suzhou Jingsi Electronic Technology Co., Ltd., with a crystal orientation of , a resistivity of 9-10Ω·cm, and a thickness of 500 μm. The ultra-high vacuum target magnetron sputtering apparatus is a DPS-III ultra-high vacuum target magnetron sputtering coating machine manufactured by Shenyang Scientific Instrument Development Center Co., Ltd., and the muffle furnace model is SX2-2.5-10A.

[0048] The porous silicon-based tungsten oxide film composite gas sensor prepared by the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com